Special spinning dividing and cutting machine for organic silica gel coating layer cloth

A technology of organic silica gel and slitting machine, which is applied in the textile field, can solve the problems of cutting without a slitting machine, troubles for operators, and wear of coated silica gel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

[0020] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0021] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

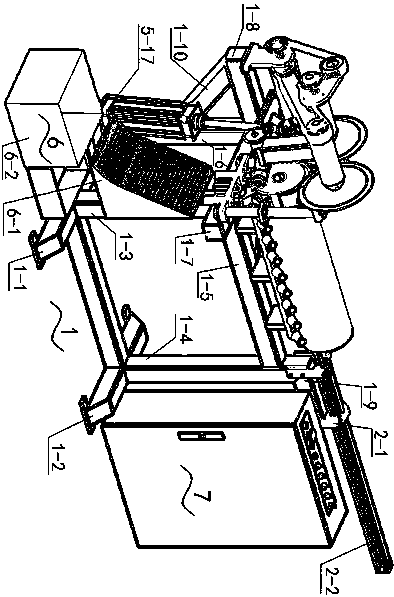

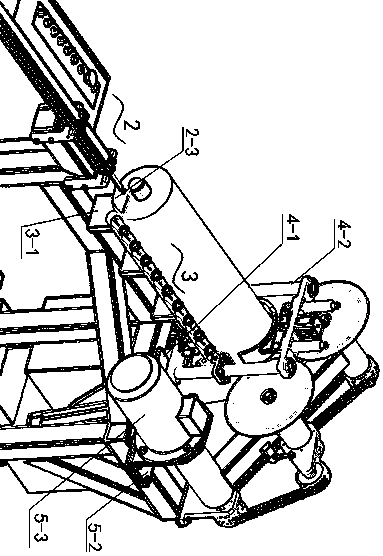

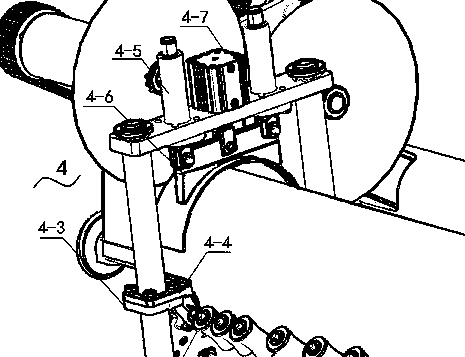

[0022] The special textile slitting machine for silicone-coated fabrics includes a bracket assembly 1, a push assembly 2, a transmission assembly 3, a clamp assembly 4, a cutting assembly 5, a recovery assembly 6, and a control assembly 7.

[0023] The bracket assembly 1 includes front legs 1-1 and rear legs 1-2 arranged in parallel, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com