Laser-assisted flexible follow-up tool electrode fine electrodeposition device and method

A tool electrode, laser-assisted technology, applied in the direction of electrodes, cells, electrolysis process, etc., can solve the problems of low shape precision of deposited bodies, enhanced forming precision of complex parts, poor localization, etc., to solve low forming precision and improve mechanical properties , Solve the effect of poor processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples, but the protection scope of the present invention is not limited thereto.

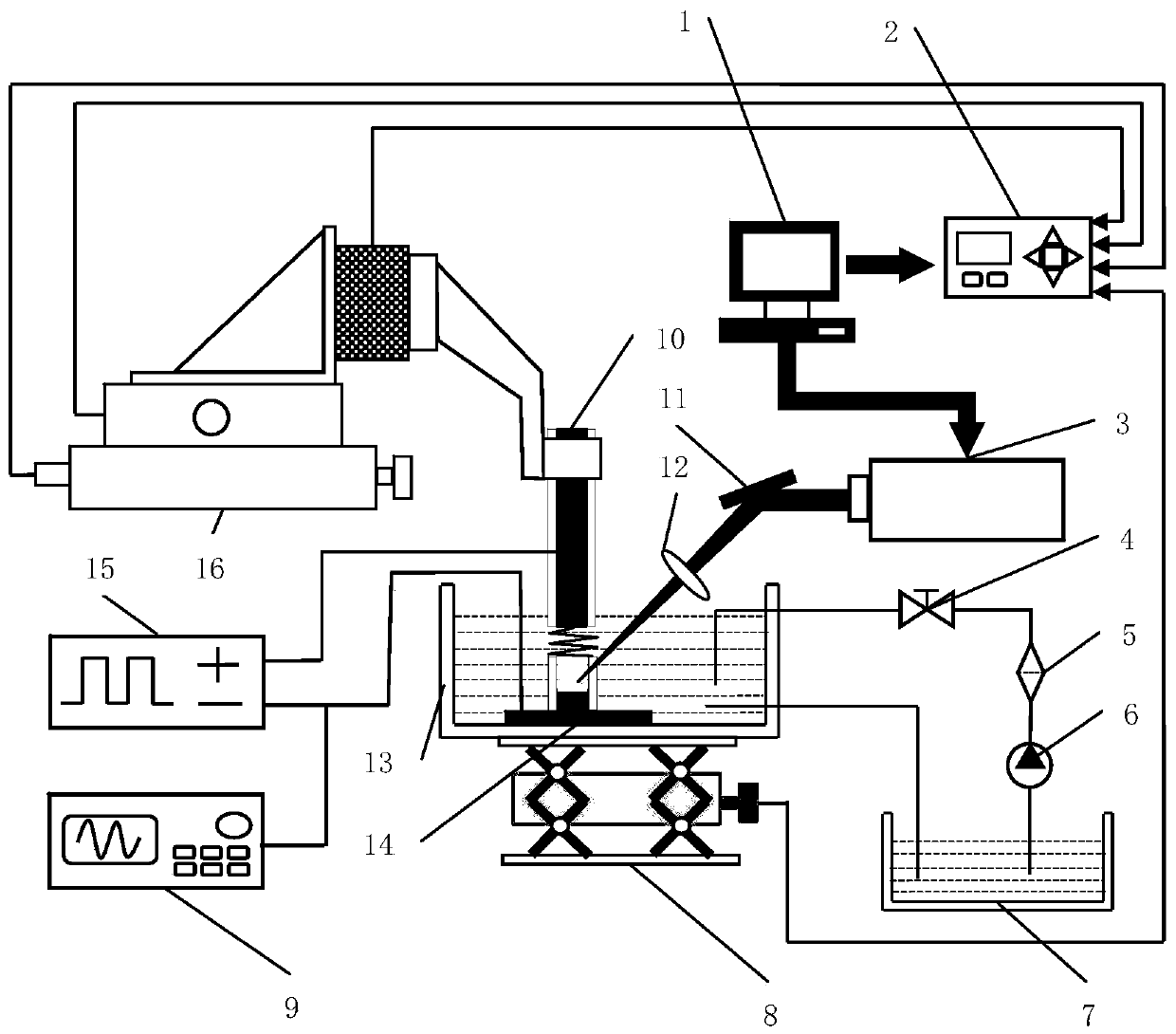

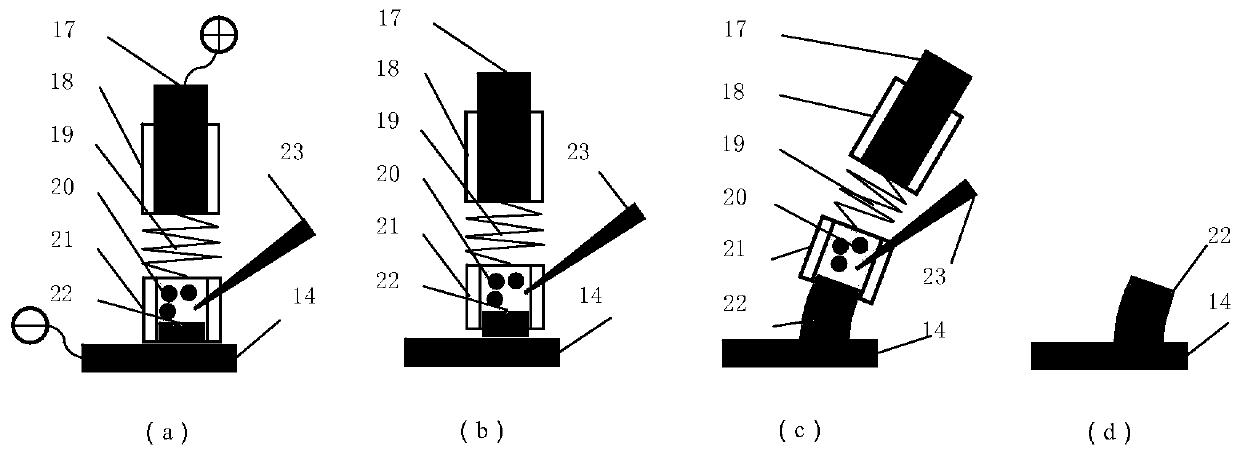

[0039] combined with figure 1, a device for laser-assisted flexible follow-up tool electrode fine electrodeposition, including a workpiece processing system, a laser irradiation system and a motion control system; the workpiece processing system includes an X-Y two-coordinate workbench 16, a vertical lifting workbench 8, DC pulse power supply 15, working tank 13, flexible follow-up tool anode 10 and cathode substrate 14; the flexible follow-up tool anode 10 is connected to the positive pole of DC pulse power supply 15 and clamped by the working arm of X-Y two-coordinate workbench 16 The cathode substrate 14 is connected to the negative pole of the DC pulse power supply 15; the flexible follow-up tool anode 10 and the cathode substrate 14 are arranged from top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com