Welding, processing, transferring and lead pressing device of storage battery pole columns

A battery and pole technology, which is applied in the field of battery pole welding, processing, and transfer lead pressing devices, can solve the problems that the transfer device does not have simultaneous transfer and flipping, affects the normal operation of the machine, and reduces production efficiency. It is easy to popularize and apply, Simple structure, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

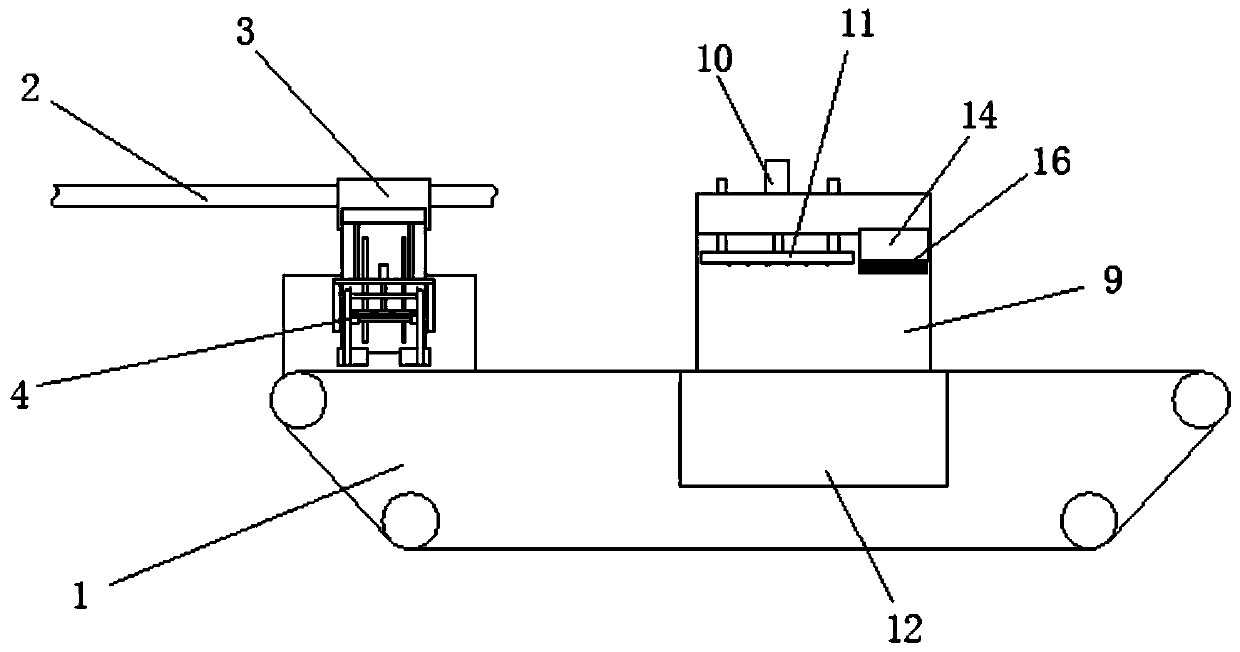

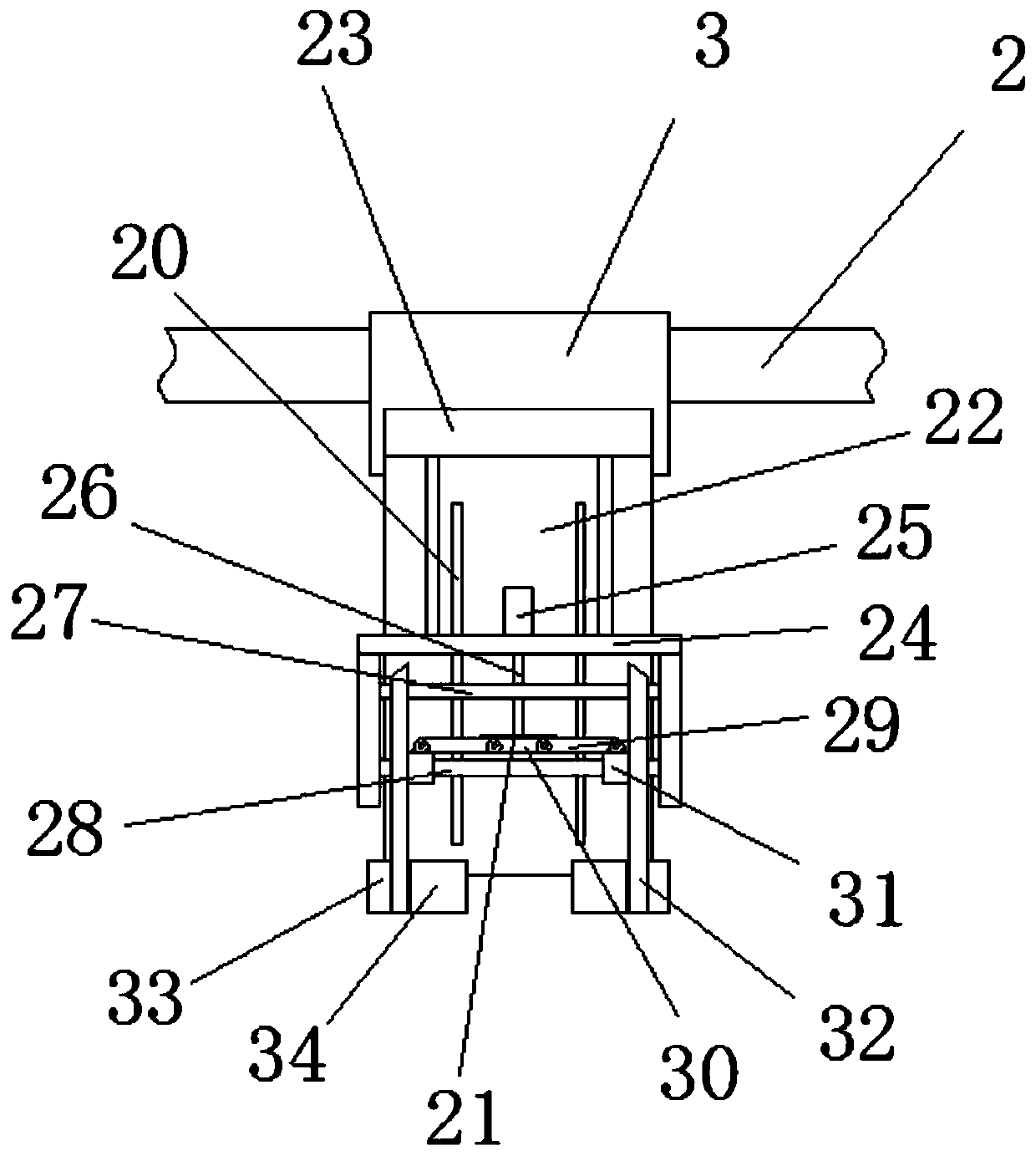

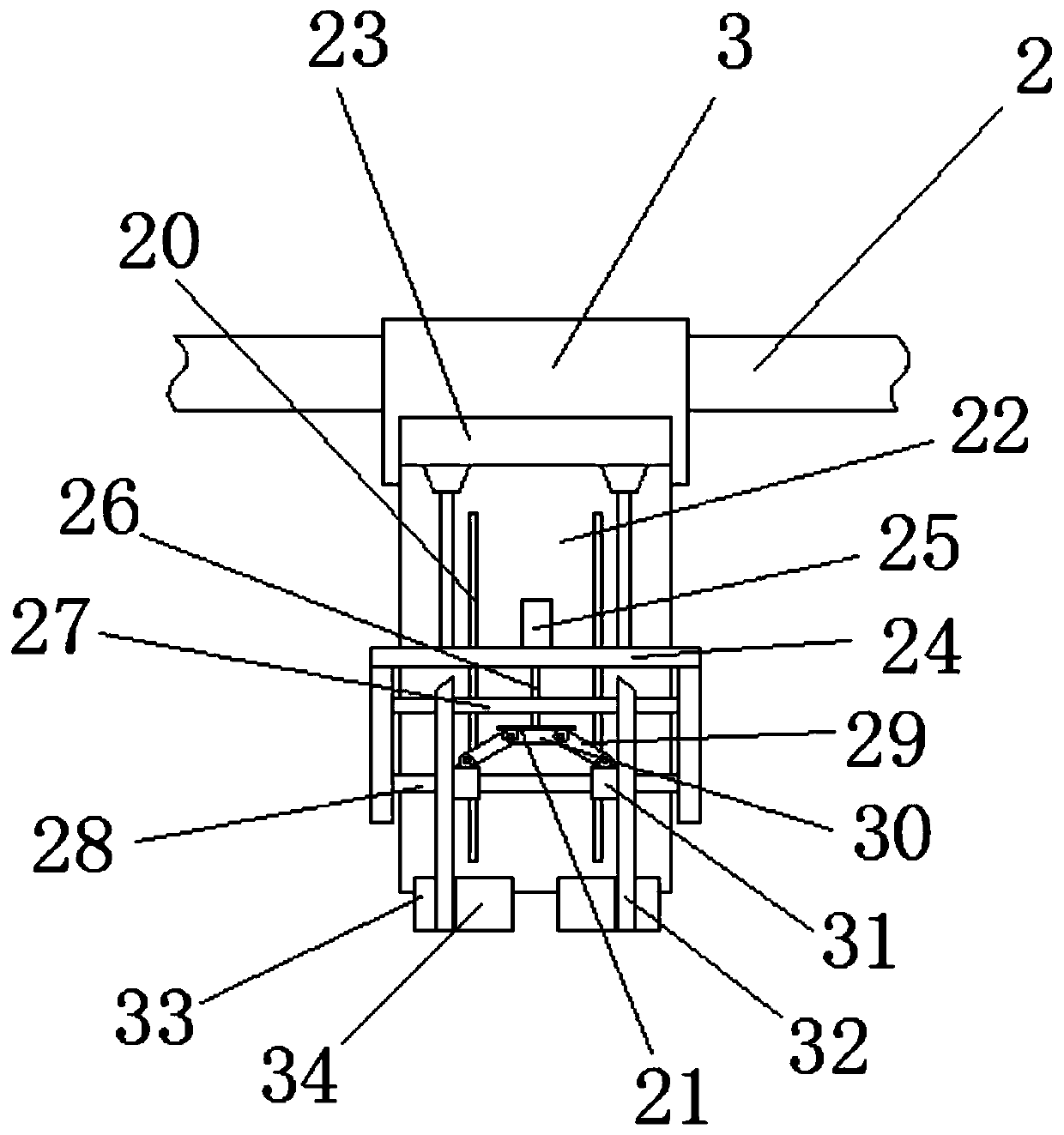

[0023] Embodiment 1: as Figure 1-6 As shown in the figure, a lead pressing device for welding, processing, and transporting battery poles includes a conveyor belt 1 and a conveyor rail 2, and both sides of the top of the conveyor belt 1 are fixedly connected with a material guide plate 17, and the material guide plate 17 is located in the recovery bin 12, the transport rail 2 is movably connected with a transport frame 3, the bottom of the transport frame 3 is fixedly connected with a mounting frame 22, and the top of the mounting frame 22 is fixedly equipped with a lifting device 23, and the lifting device 23 The bottom of the U-shaped mounting frame 24 is fixedly connected, and the inner wall of the U-shaped mounting frame 24 is fixedly connected with the first guide rod 28 and the second guide rod 28 in sequence from top to bottom, and the U-shaped mounting frame 24 The top is fixedly equipped with a cylinder 25, the bottom of the cylinder 25 is equipped with a telescopic ...

Embodiment 2

[0024] Embodiment 2: as figure 1 As shown, a lead pressing device for battery pole welding, processing, transfer, and transportation includes a conveyor belt 1 and a conveyor rail 2. The conveyor belt 1 is provided with anti-skid lines, and the conveyor rail 2 is movably connected with a conveyor frame 3. The bottom of the delivery frame 3 is fixedly connected with a mounting frame 22, and the front side of the mounting frame 22 is fixedly equipped with two sets of slide rails 20, and the top of the mounting frame 22 is fixedly equipped with a lifting device 23, and the bottom of the lifting device 23 A U-shaped mounting frame 24 is fixedly connected, and the U-shaped mounting frame 24 is movably connected with the slide rail 20. The inner walls of the U-shaped mounting frame 24 are sequentially fixedly connected with a first guide rod 28 and a second guide rod 28 from top to bottom. Guide rod 28, the top of the U-shaped mounting frame 24 is fixedly equipped with a cylinder 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com