Integrated brushless motor used for automobile EPS

A brushless motor and integrated technology, applied in the direction of electric steering mechanism, etc., can solve the problems of complex structure, large space occupation, and reduced reliability of automotive EPS systems, and achieve simple structure, small space occupation, and increased speed and torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

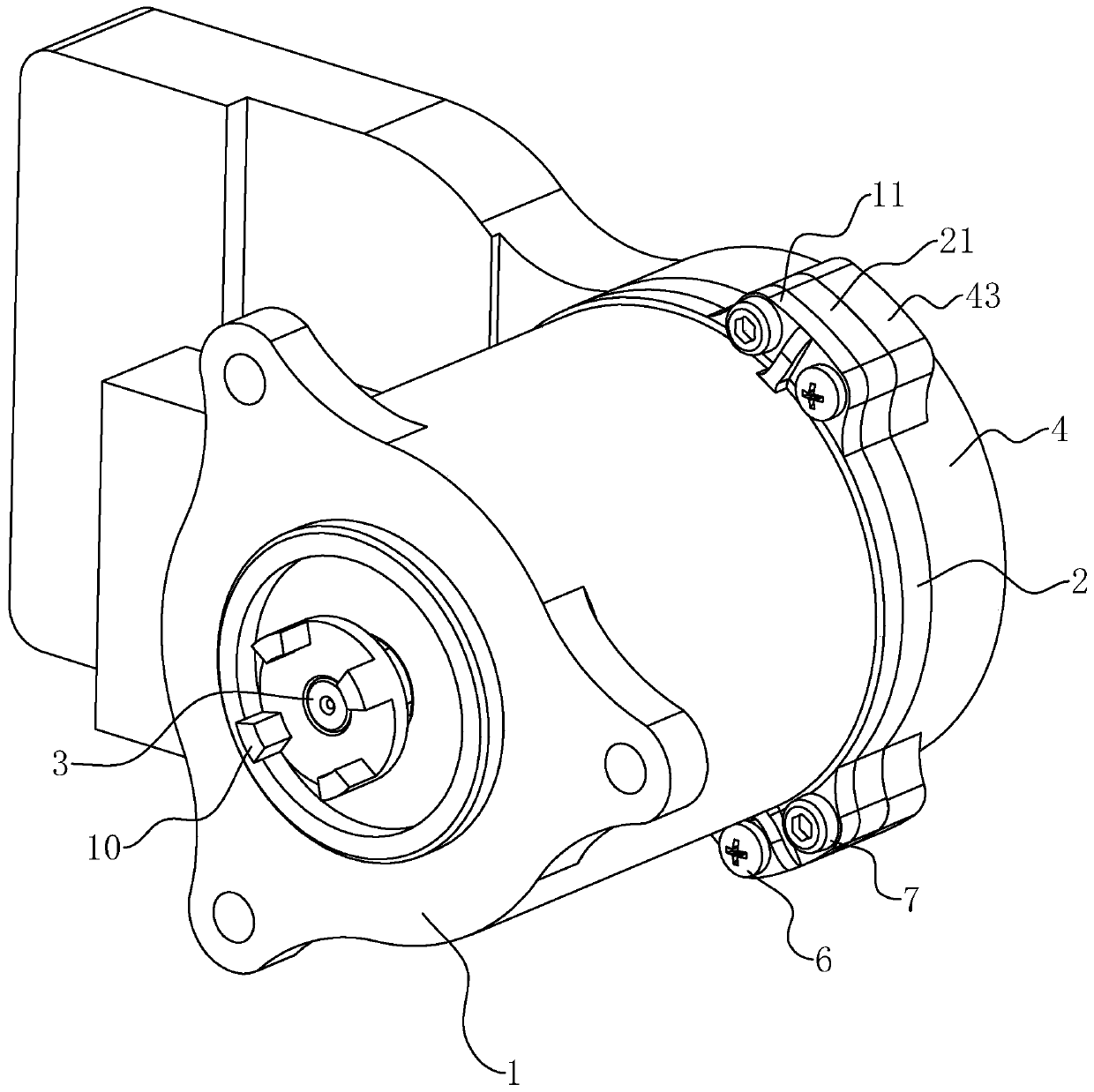

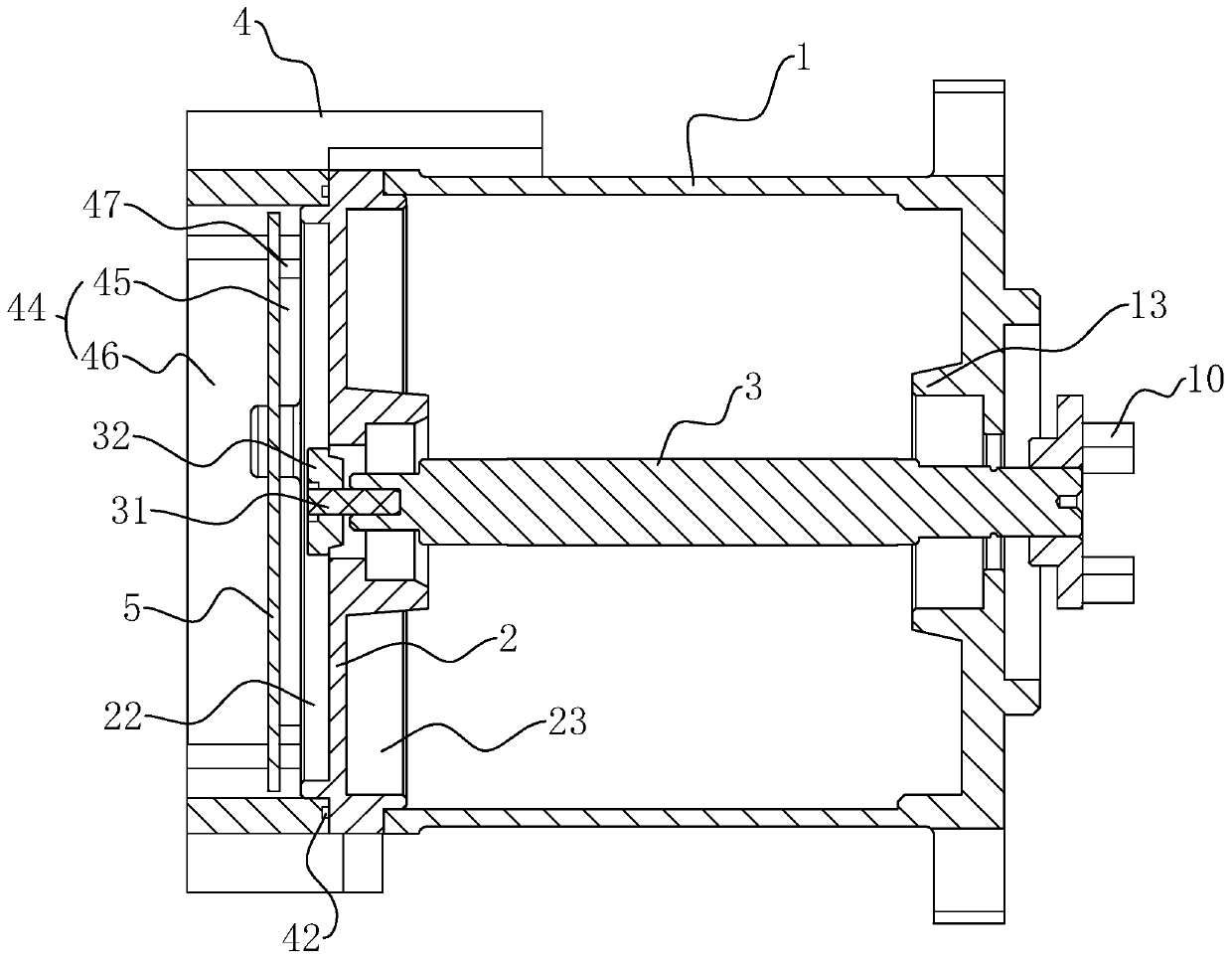

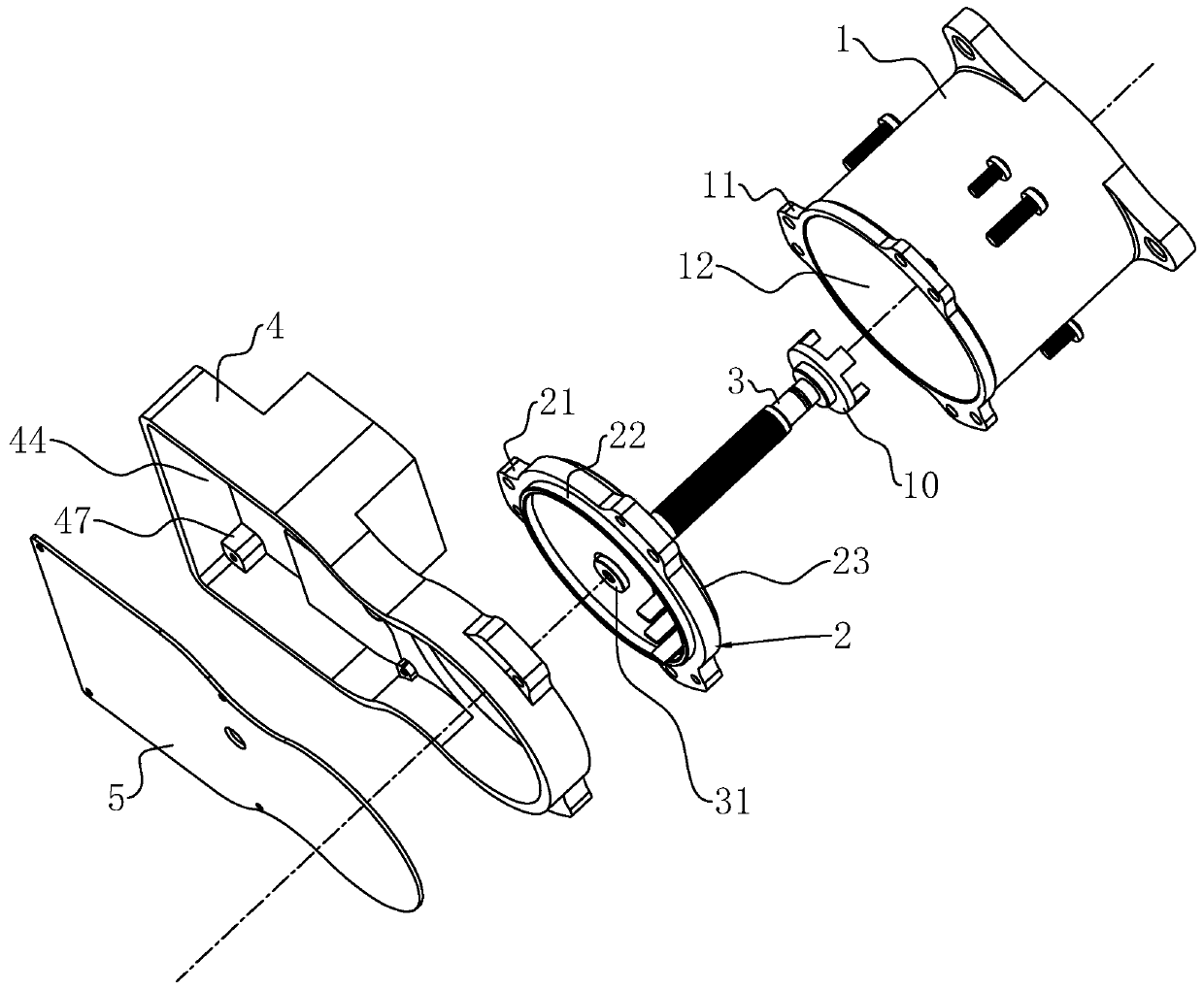

[0037] With reference to the accompanying drawings, the brushless motor for the integrated automotive EPS will be further described.

[0038] An integrated brushless motor for automotive EPS, such as figure 1 with figure 2 As shown, it includes a housing 1, a rear cover 2 arranged at one end of the housing 1, a rotating shaft 3 respectively rotated on the rear cover 2 and the housing 1 at both ends, a controller housing 4 connected to the rear cover 2, and a set The partition 5 arranged on the controller housing 4 and in a gap with the rear cover 2; the partition 5 is provided with a gap between the inner wall of the cavity 44, and the partition 5 is a heat-dissipating insulating plate.

[0039] Such as figure 1 As shown, wherein, the first mounting seat 11 is provided on the circumferential side wall of the housing 1, and the extension edge 21 matched with the first mounting seat 11 is provided on the back cover 2, and the first mounting seat 11 and the The extension 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com