Large-tonnage tunnel engineering heavy haul train electrical control system

An electrical control system and tunnel engineering technology, applied to locomotives and other directions, can solve problems that affect the progress of tunnel construction, low stability, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

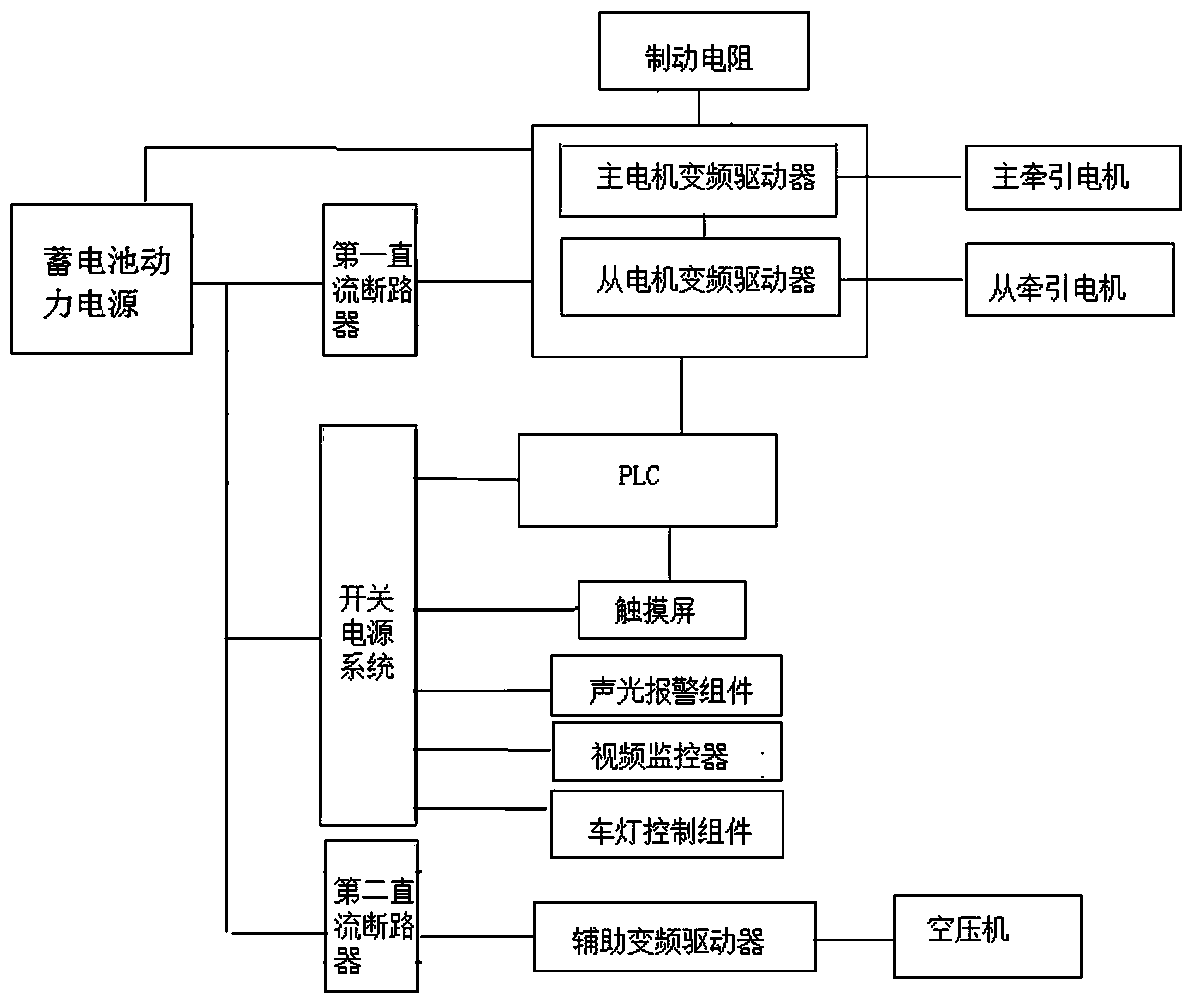

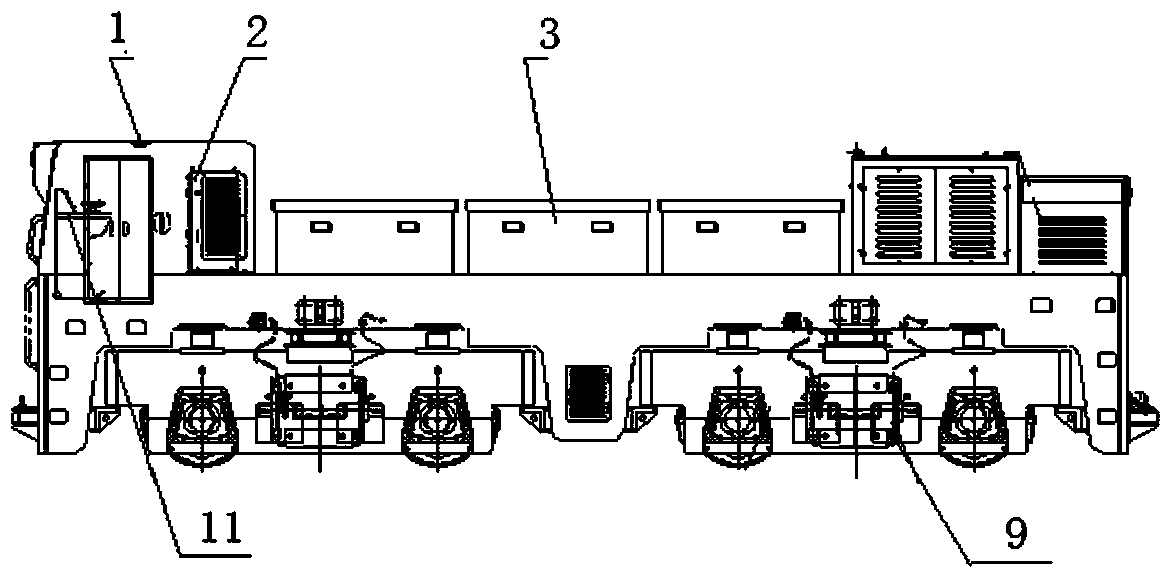

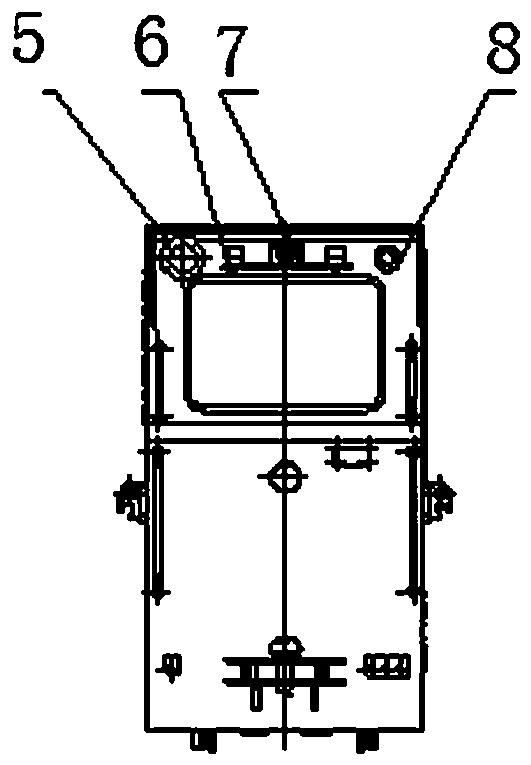

[0023] refer to Figure 1-Figure 4, electrical control system for heavy-duty trains in large-tonnage tunnel projects, including battery power supply, main motor variable frequency drive, slave motor variable frequency drive, switching power supply system, PLC, main traction motor, slave traction motor, touch screen, sound and light alarm components, video surveillance inverter, lamp control components, auxiliary variable frequency drive, air compressor, braking resistor, main motor variable frequency drive and slave motor Drive connection, the variable frequency driver of the main motor is connected with the main traction motor, the variable frequency driver of the slave motor is connected with the traction motor, the variable frequency driver of the main motor and the variable frequency driver of the slave motor are connected with the braking resistor, the variable fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com