Train storage battery traction system and method and train

A technology of traction system and storage battery, applied in locomotive propulsion mode, electric vehicle charging technology, locomotive, etc., can solve the problems of wasting power supply energy, wasting hardware resources, and wasting resources, so as to save hardware resources and costs, reduce complexity, The effect of improving usage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

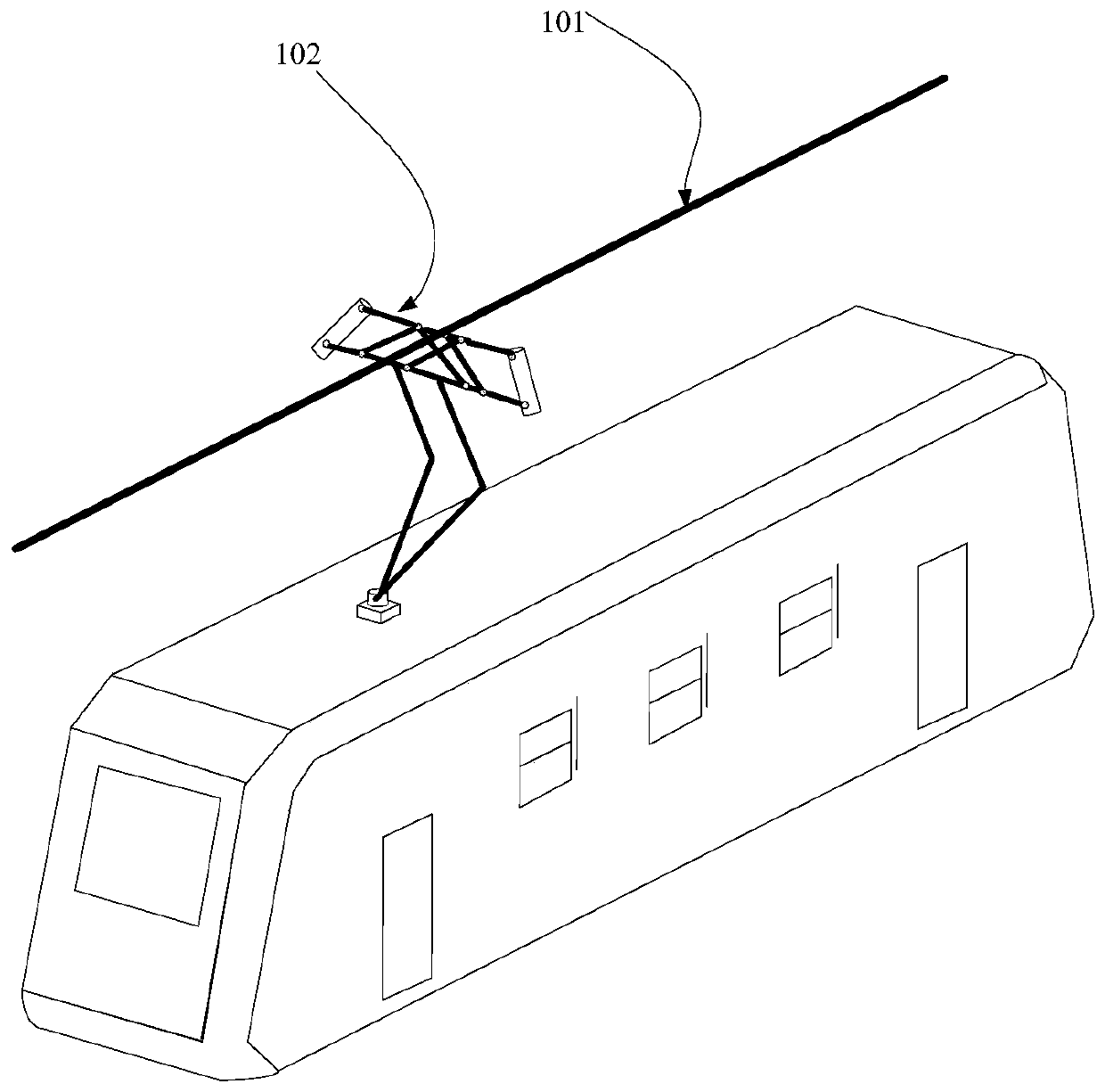

[0044] An embodiment of the present application provides a train battery traction system, which will be described in detail below with reference to the accompanying drawings.

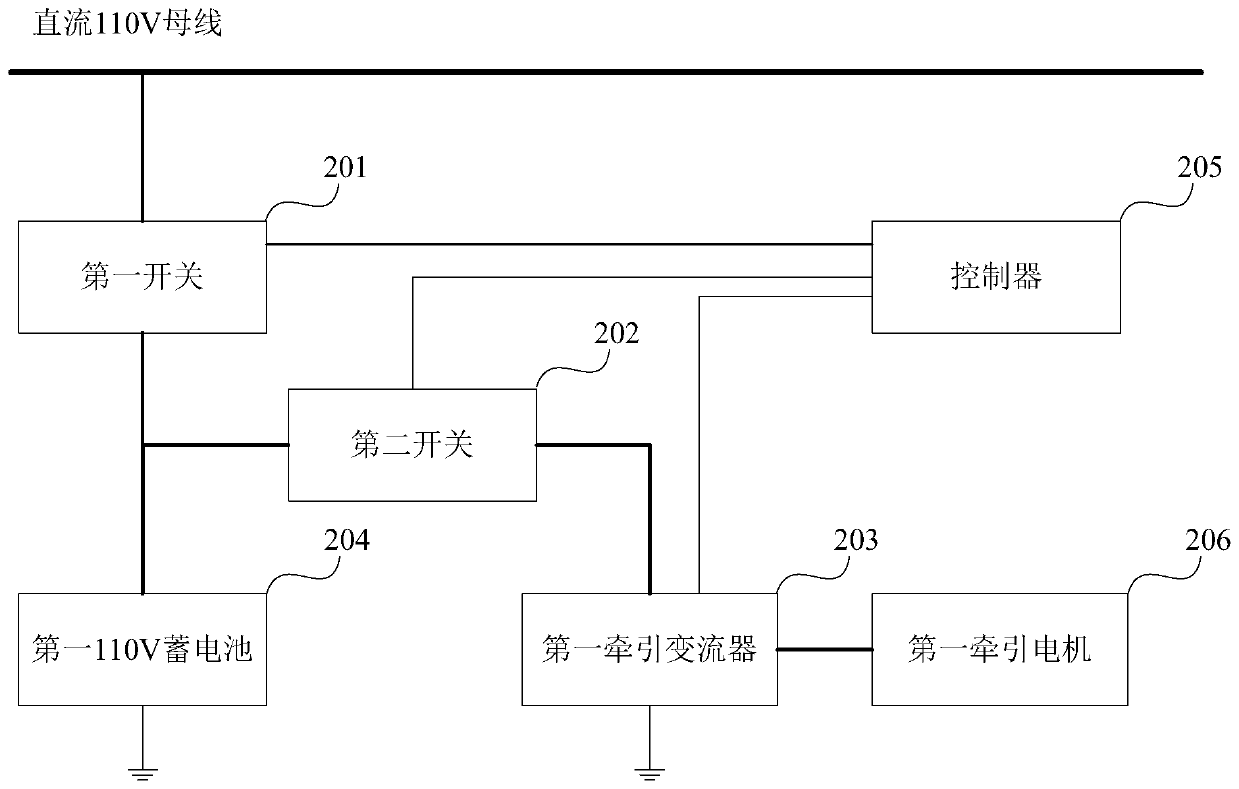

[0045] see figure 2 , which is a train battery traction system provided in Embodiment 1 of the present application.

[0046] The system includes: a first switch 201 , a second switch 202 , a first traction converter 203 , a first 110V battery 204 and a controller 205 . Furthermore, the first traction converter 203 is also connected to the first traction motor 206 .

[0047] It should be noted that "first" and "second" in the embodiments of the present application are only for convenience of explanation and description, and have no limiting function.

[0048] The first switch 201 and the second switch 202 may be circuit breakers, which are used to control the on-off of the circuits where they are located.

[0049] The first 110V battery 204 is connected to a DC 110V bus through the first switch 201 ....

Embodiment 2

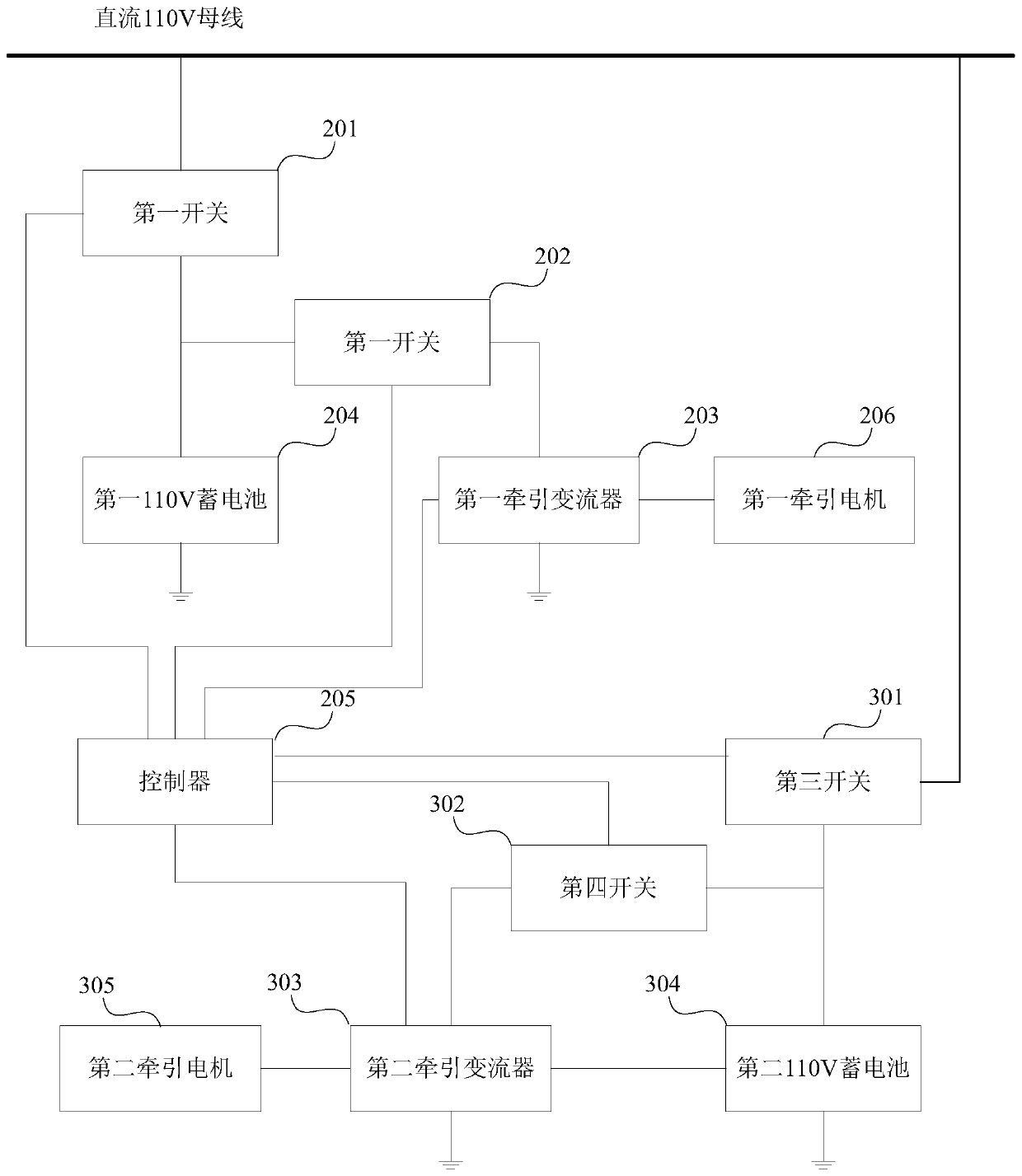

[0061] see image 3 , which is a schematic diagram of another train battery traction system provided in Embodiment 2 of the present application.

[0062] see also Figure 3a , which is a schematic diagram of a specific connection mode of the train battery traction system provided in Embodiment 2 of the present application.

[0063] The system described in the embodiment of the present application is based on the system described in the first embodiment, and further includes a backup part: a third switch 301 , a fourth switch 302 , a second traction converter 303 and a second 110V battery 304 . Furthermore, the second traction converter 303 is also connected to the second traction motor 305 .

[0064] It should be noted that the "third" and "fourth" in the embodiments of the present application are only for convenience of explanation, and have no limiting function.

[0065] The third switch 301 and the fourth switch 302 may be circuit breakers, which are used to control the ...

Embodiment 3

[0080] see Figure 4 , which is a schematic diagram of another train battery traction system provided in Embodiment 3 of the present application.

[0081] The system described in the embodiment of the present application adds a signal acquisition device 401 on the basis of the system described in the third embodiment.

[0082] The signal collection device 401 is configured to determine whether the first pantograph and the second pantograph are raised, and send the results of the first pantograph and the second pantograph raised to the controller 205 .

[0083] The controller 205 may be a control computer of the train.

[0084] Specifically, the signal acquisition device 401 is configured to send the ID of the first pantograph and the effective identifier of the hoisting bow to the controller 205 when the first pantograph is hoisting; When the second pantograph is raising the pantograph, the ID of the second pantograph and the effective identification of the lifting bow are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com