Convex point pressing roller device

A pressure roller device and technology of bumps, applied in the field of conveyor belt forming equipment, can solve the problems of reducing initial tack and bonding strength, unfavorable vulcanization process, production and operation troubles, etc., to improve local initial tack and enhance local tack Effect, the effect of improving product quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

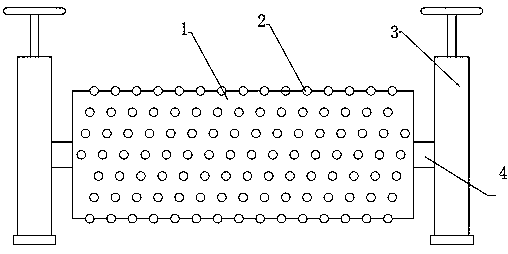

[0030] like Figure 1-Figure 5 As shown, the bump pressure roller in the bump pressure roller device of the present invention includes a pressure roller body 1, a bump 2, a pressure roller shaft 4, and a lifting distance adjustment mechanism 3; wherein:

[0031] like Figure 1-Figure 2 As shown, the pressure roller body 1 has a cylindrical structure and is arranged on the pressure roller shaft 4 . A number of screw holes are evenly distributed along the helical direction on the pressure roller body 1, and the above screw holes can form a screw fit with the bump connecting portion 2-2.

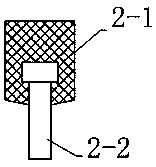

[0032] like Figure 1-Figure 4 As shown, there are several bumps 2, which are evenly distributed on the outer cylindrical surface of the pressure roller body 1 along the helix; the tops of all the bumps are located on the same cylindrical surface. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com