Clamping test bench of tunnel protective door, and wind pressure testing system comprising clamping test bench

A test system and protective door technology, applied in aerodynamic test, mechanical component test, machine/structural component test, etc., can solve problems such as restricting the safe application of tunnel protective doors, relying on field testing, and single test conditions. Achieve the effect of shortening loading time, high loading efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0041] In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

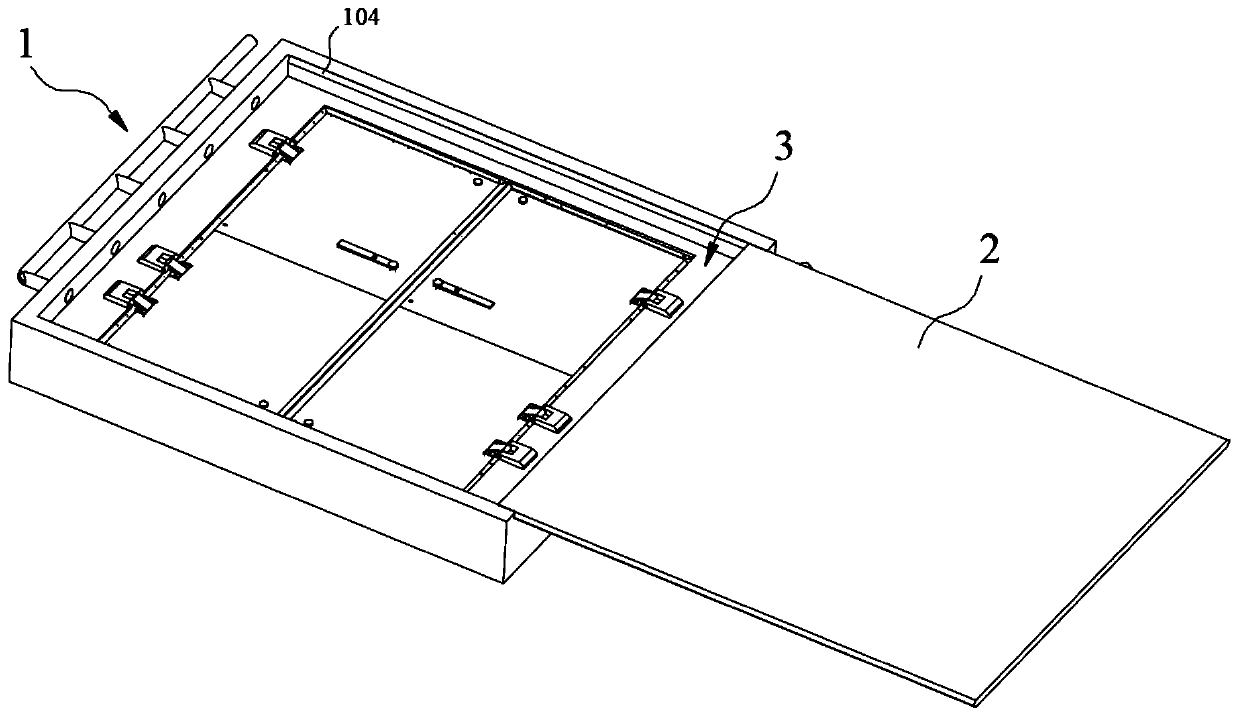

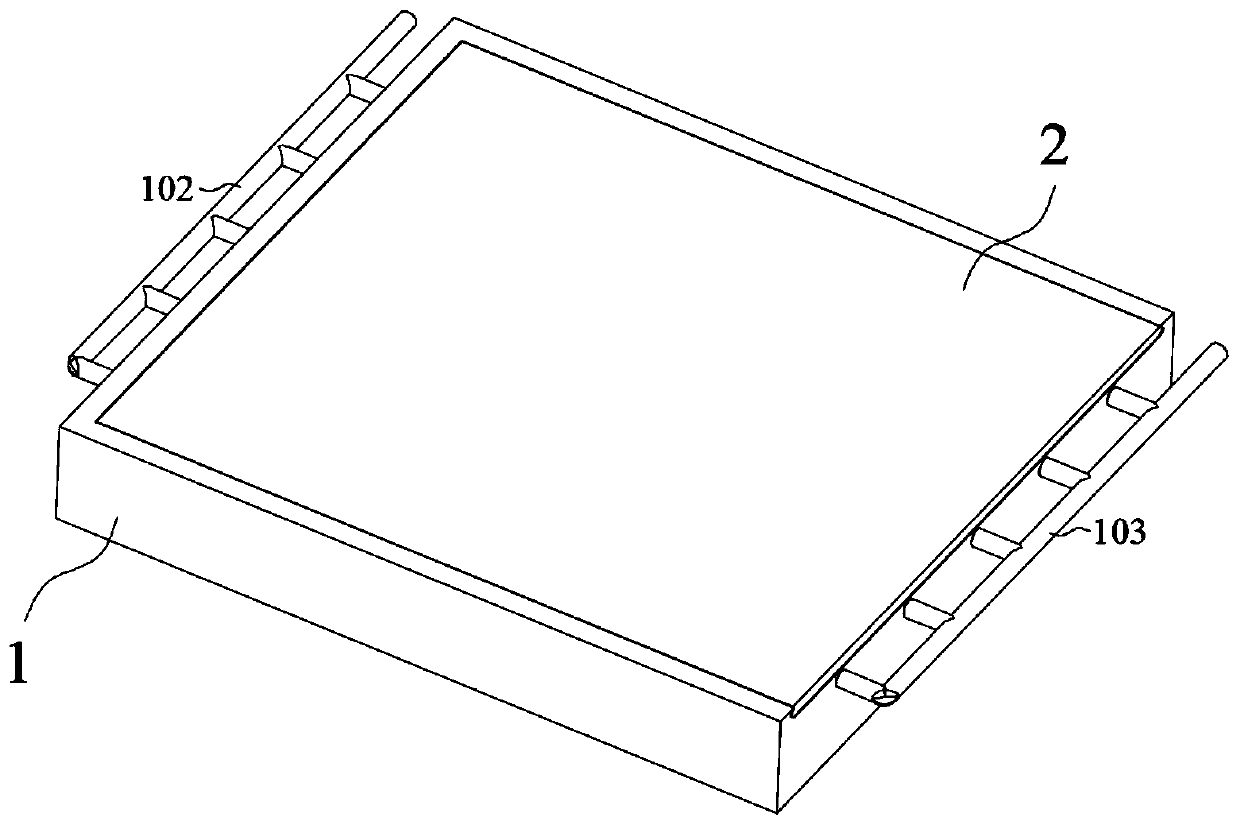

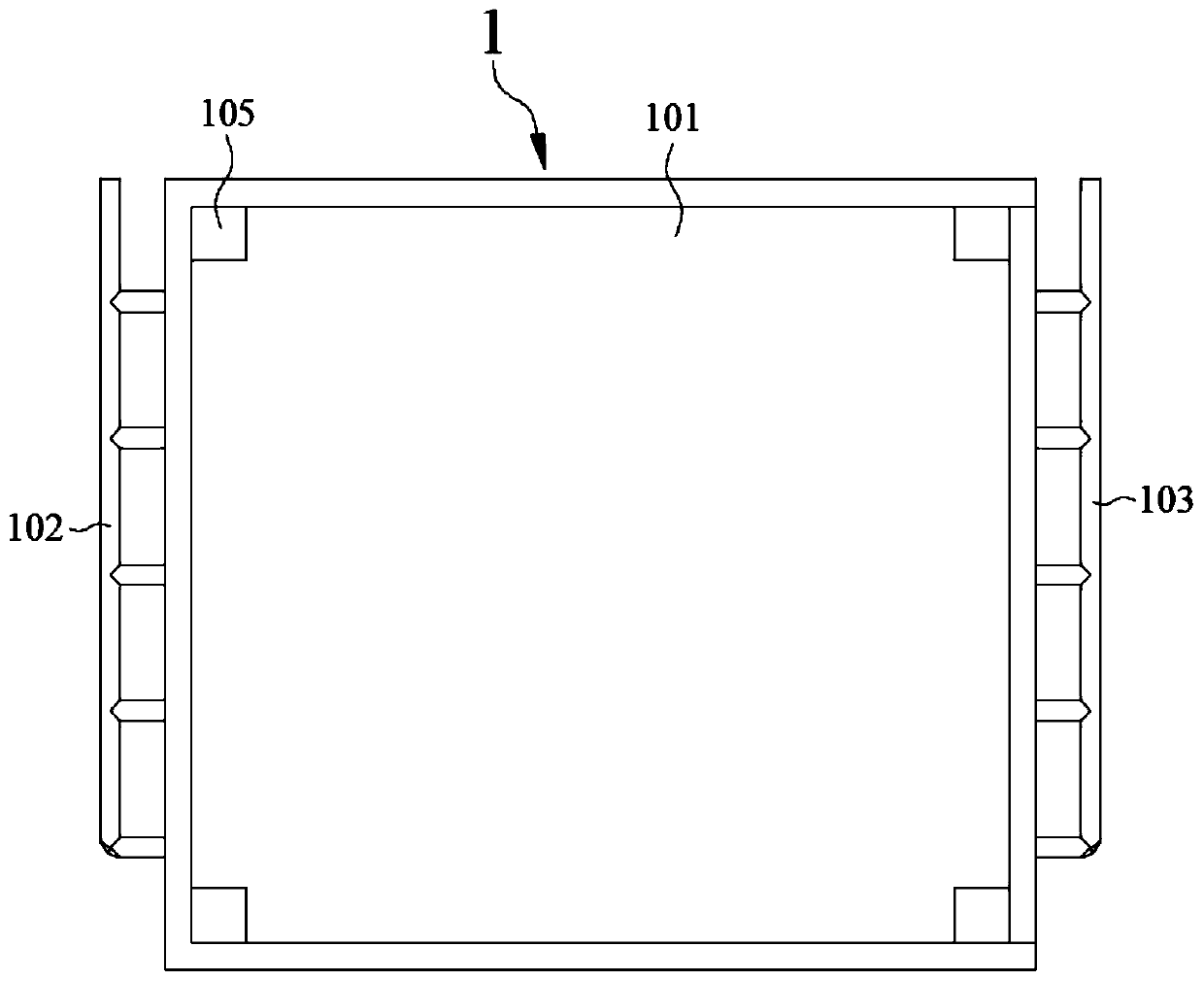

[0042] The clamping test bench of the tunnel protective door in the preferred embodiment of the present invention is as follows: Figure 1~3 Shown in, and the protective door assembly 3 to be tested in the preferred embodiment is as Figure 4 shown in . Wherein, the clamping test bench includes a test bench body 1 and a test bench sliding cover 2 . Wherein, the test bench body 1 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com