Method for improving accuracy of automatic monitoring of flue gas emission

An automatic monitoring and emission technology, applied in office automation, volume indication and recording equipment, data processing applications, etc., can solve problems such as instrument blockage, difficulty in measuring flue gas flow rate, and inaccurate flue gas flow measurement, so as to avoid consumption time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

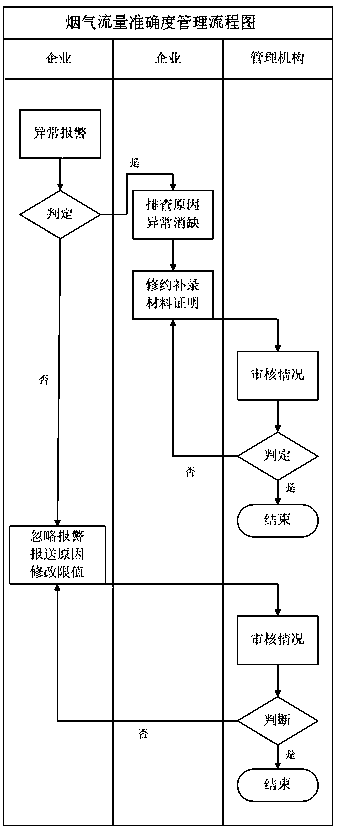

[0022] see figure 1 , a method to improve the accuracy of automatic monitoring of flue gas emissions, adopting "one machine, one policy" to manage the flue gas flow of the unit, that is, by setting the normal range of flue gas flow for each unit (the flue gas flow is normal The change range is between the minimum value and the maximum value of the normal flue gas flow of the unit in the previous year), when the flue gas flow exceeds the set range during the operation of the unit, the system will automatically send an abnormal alarm to the enterprise, and the enterprise management personnel will receive it. Judging the early warning after the abnormal alarm is received. If the alarm is true, the management personnel should immediately check the cause of the abnormal alarm and eliminate the abnormality. The data needs to be uploaded with relevant certification materials), and submitted to the management agency personnel for review. If the management agency personnel pass the rev...

Embodiment 2

[0027] The normal value of the flue gas flow rate of a million-level coal-fired unit of enterprise A last year was 3923m at most 3 / h, the minimum is 2548m 3 / h, at the beginning of this year, the online monitoring platform set the flue gas flow range as 2548-3923m 3 / h. When the million-level coal-fired unit is running on a certain day, the flue gas flow rate is 1452m in a certain hour 3 / h, the system automatically sends an abnormal alarm. After the enterprise management personnel find the abnormal alarm, they immediately check the cause and find that the flue gas flow meter is blocked, which makes the measurement result too small. The actual flue gas flow rate for this hour is 3289m 3 / h, after the enterprise management personnel cleaned the meter, the meter measurement returned to normal. Finally, the enterprise, in accordance with the data revision regulations on the system, corrected and supplemented the data from the alarm occurrence to the data recovery to normal val...

Embodiment 3

[0029] A certain 600,000-class coal-fired unit of B company last year had a maximum flue gas flow rate of 2373m 3 / h, the minimum is 1496m 3 / h, the online monitoring platform set the flue gas flow range at the beginning of this year as 1496-2373m 3 / h. When the 600,000-class coal-fired unit is running on a certain day, the flue gas flow rate is 1200m in a certain hour 3 / h, the system automatically sends an abnormal alarm. After the enterprise management personnel find the abnormal alarm, they find that the flue gas flow value of the hour is true, and the reason is that the flue gas flow exceeds the set range. The coal-fired unit is controlled to operate at a lower load, and the range of flue gas flow during this special period is 1033-1441m 3 / h. After the enterprise management personnel click to ignore the alarm, they fill in and submit the pop-up reason explanation and modification limit value in turn. The management agency verifies that the situation is true, the conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com