Slotting blast hole layout structure for blind raise once well completion and well completion method

A technology for arranging structures and cutting holes, which can be used in sinking, shaft equipment, earthwork drilling and mining, etc. It can solve problems such as difficulty in reaching the design well depth, high blast vibration hazards, long drilling time period, etc., and achieve weakening of the rock mass Damage damage phenomenon, high construction precision, effect of reducing construction time period and excavation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the construction in an underground mine whose lithology is above medium hardness is taken as an example to describe in detail, and a field blasting construction is carried out at the level of -485m. The height of the blind raised shaft is designed to be 10m. Its diameter is 2.0 m.

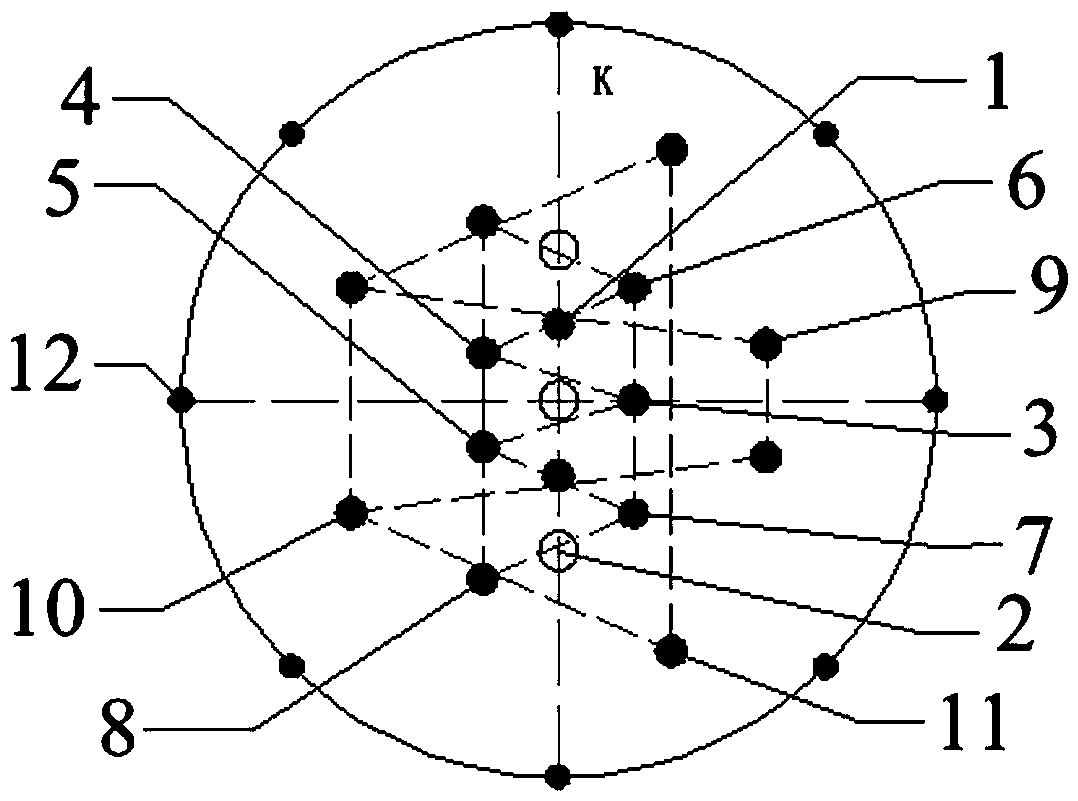

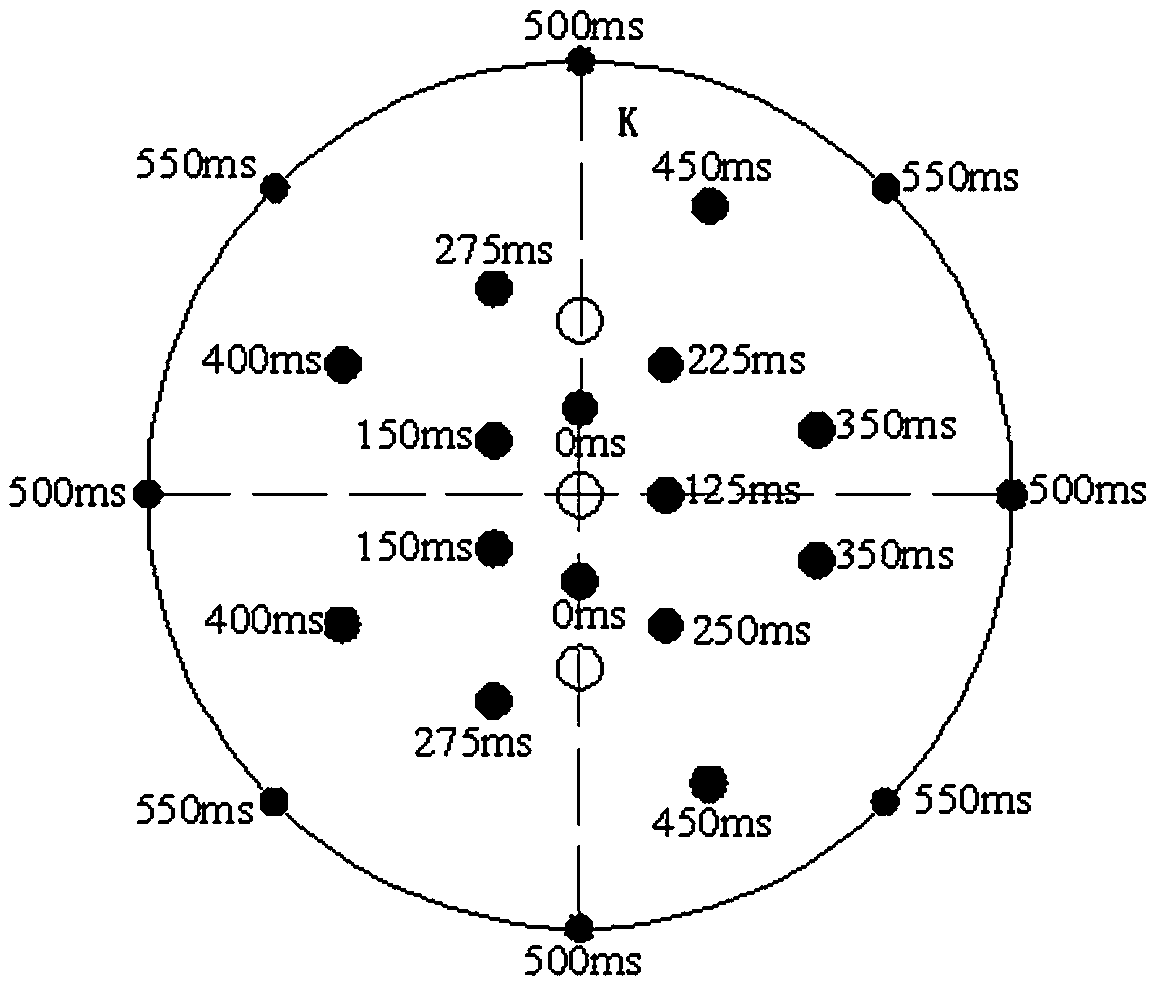

[0030] see figure 1 , the present invention provides a cutting blast hole layout structure for a blind patio well to be formed at one time. A linear cutting hole is provided on one of the center lines K of the blasting area, and the linear cutting hole consists of three empty holes 2 and two Charge holes 1 are alternately arranged.

[0031] The blasting area is provided with a triangular cut hole, and the triangular cut hole consists of a first-level triangular cut hole 3, two second-level triangular cut holes 4 and 5, and two third-level triangular cut holes 6. and 7, two fourth-level triangular cut holes 8, the first-level triangular cut hole 3 is vertically arranged ...

Embodiment 2

[0040] On the basis of Embodiment 1, this embodiment provides a method for forming a blind well at one time, including the following steps:

[0041] Step 1: On the end face of the circular blasting area of the blind patio, use a medium-deep hole drilling rig to drill a linear cut hole along one of the center lines K. Holes and two charge holes are arranged alternately, the distance between each two adjacent linear cut holes is 0.2m, the charge hole diameter is 76mm, and the empty hole diameter is 102mm to form a linear cut hole Arrangement, the depth of the five blastholes is 50-100cm deeper than the height of the designed blind patio;

[0042] Step 2: Drill triangular cut holes on both sides of the center line described in step 1. The aperture of the triangular cut holes is 76mm; Cutting holes, two third-level triangular cutting holes and two fourth-level triangular cutting holes, the first-level triangular cutting holes are vertically set on the side 0.2m away from the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com