Low-nitrogen gas burner achieving automatic adjustment of flame shape

A gas burner and automatic adjustment technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of mismatched flame shapes of new burners, furnace surge, limited adjustment amount, etc., to improve safety. and economy, eliminate residual rotation, realize the effect of real-time adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

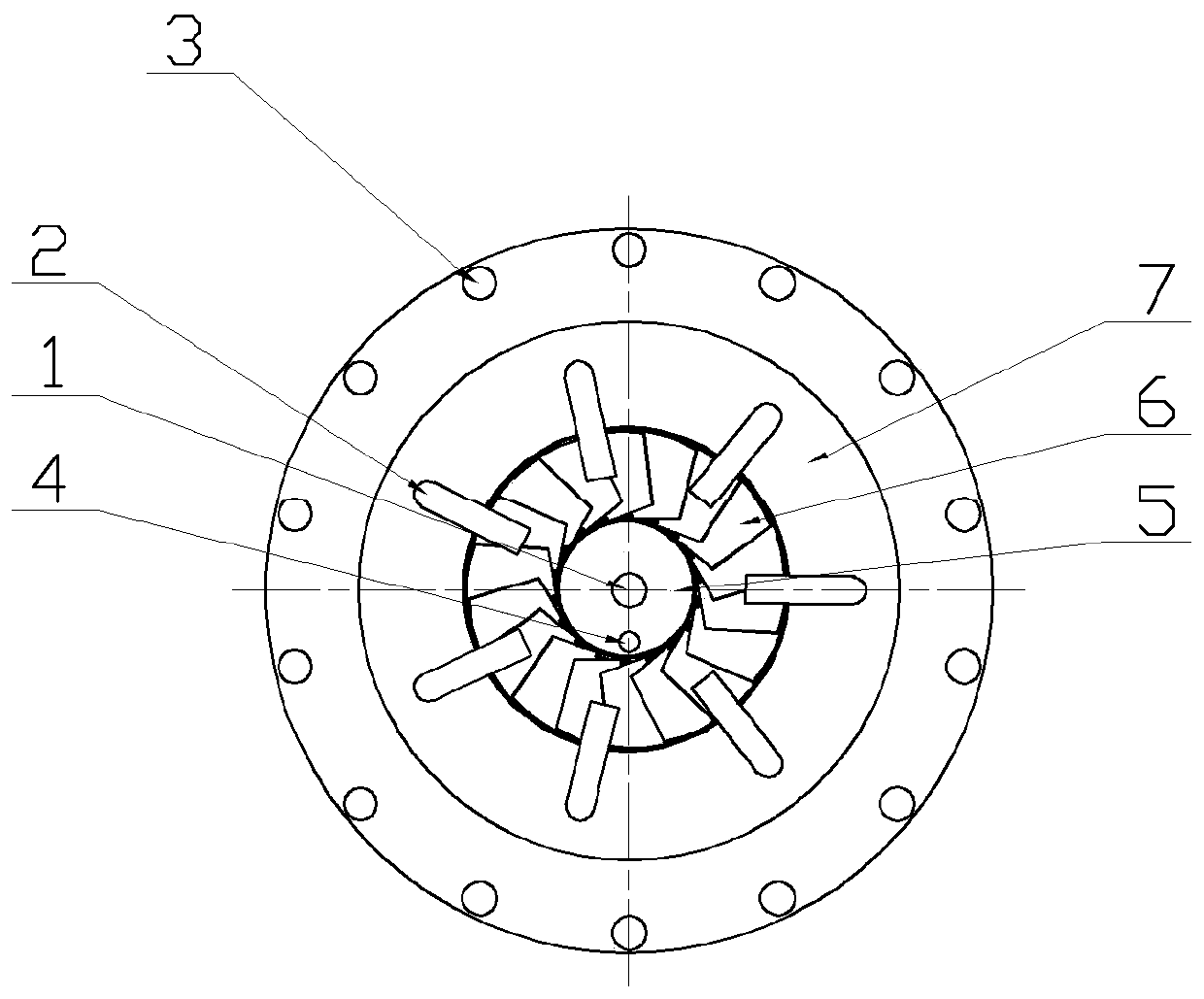

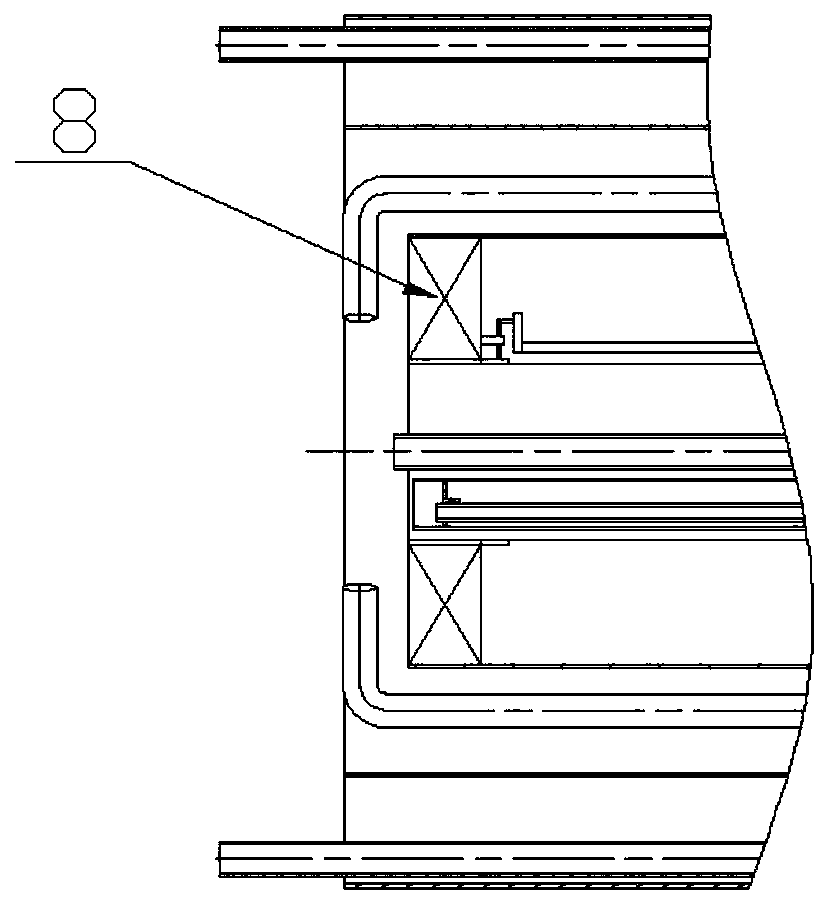

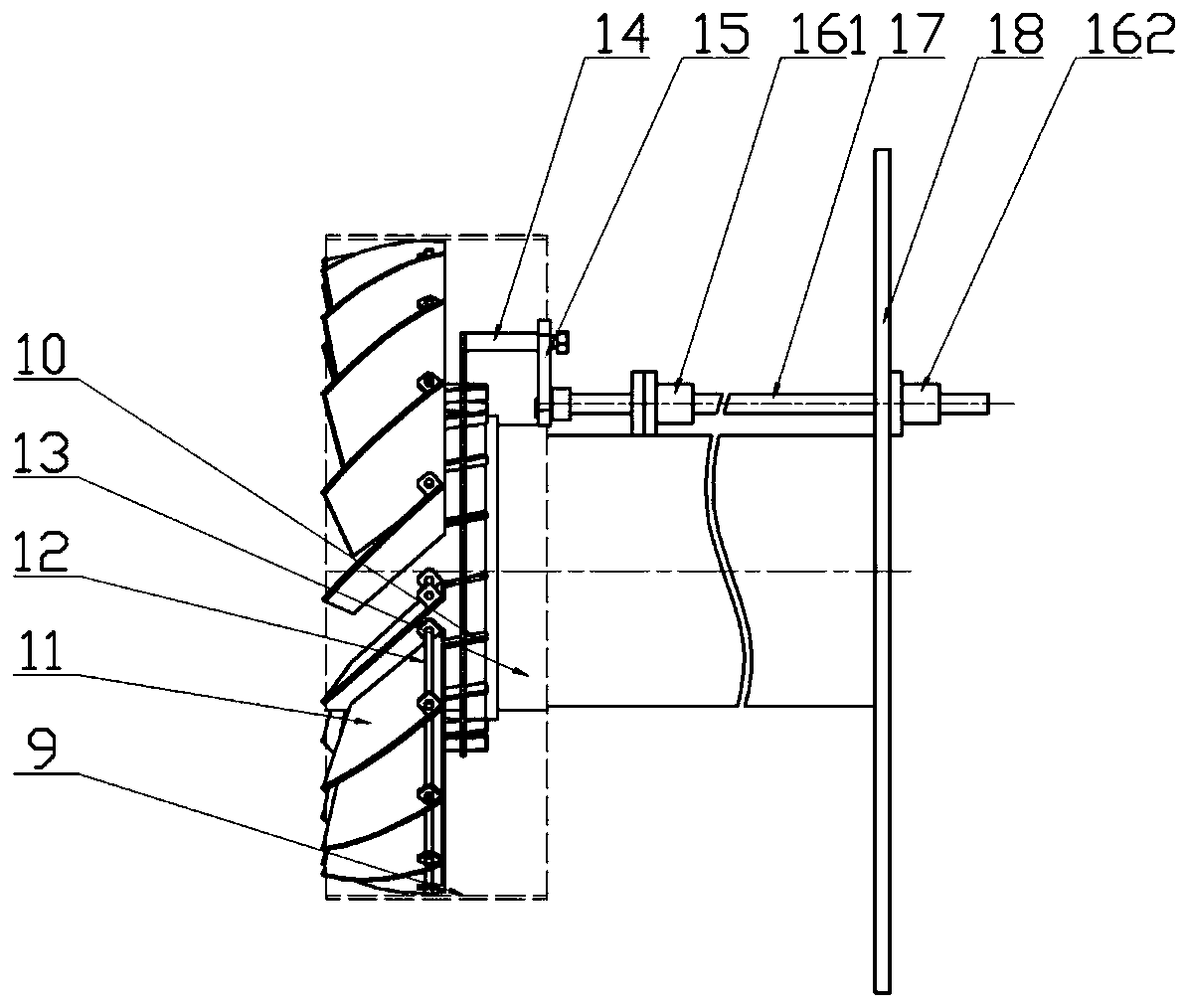

[0024] refer to figure 1 , figure 2 and image 3 , the low-nitrogen gas burner with automatic flame shape adjustment according to the present invention includes an inner air duct 13, an outer air duct 9, a casing, a swirl disc 8, an actuator, several primary fuel spray guns 1, several ignition spray guns 4, several The secondary fuel spray gun 2 and several tertiary fuel spray guns 3; the inner air cylinder 13, the outer air cylinder 9 and the casing are empty from the inside to the outside in turn, and the primary air passage 5 is formed in the inner air cylinder 13, and the inner air cylinder 13 and the outer air cylinder The secondary air passage 6 is formed between the air cylinders 9, the tertiary air passage 7 is formed between the outer air cylinder 9 and the box shell, the secondary air passage 6 is provided with a swirl disc 8, the primary fuel spray gun 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com