Reinforcing device of pneumatic motor

A reinforcement device, air motor technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as unfavorable protective cover protection, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in connection with the drawings and embodiments.

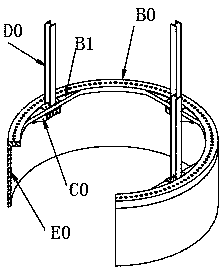

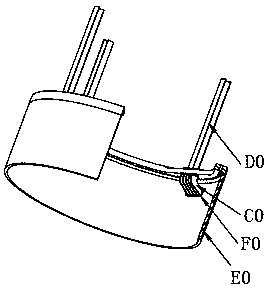

[0028] Such as Figure 1-Figure 5 As shown, the reinforcement device of the air motor and the reinforcement device of the protective cover can be equipped on the outer and inner sides of the protective cover of the air motor, and are used for additional facilities such as automatic control devices and metal structures that must be equipped under pressure; It can ensure that the protective cover is not damaged by a large strain, and the effect of not hindering its structural requirements is achieved.

[0029]The protective cover reinforcing device is equipped on the inner edge of the protective cover, and there is no welding between the surface of the protective cover, and several positioning areas F0 are equipped with equidistant positioning on the protective cover subsection E0 of the protective cover used to equip the air motor, so as to This constrains the moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com