Production method of blueberry wine

A production method and technology for blueberry wine, which are applied in the field of food fermentation, can solve the problems of low anthocyanin content and low blueberry alcohol content, and achieve the effects of increasing the content of active ingredients, improving stability and adjusting taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

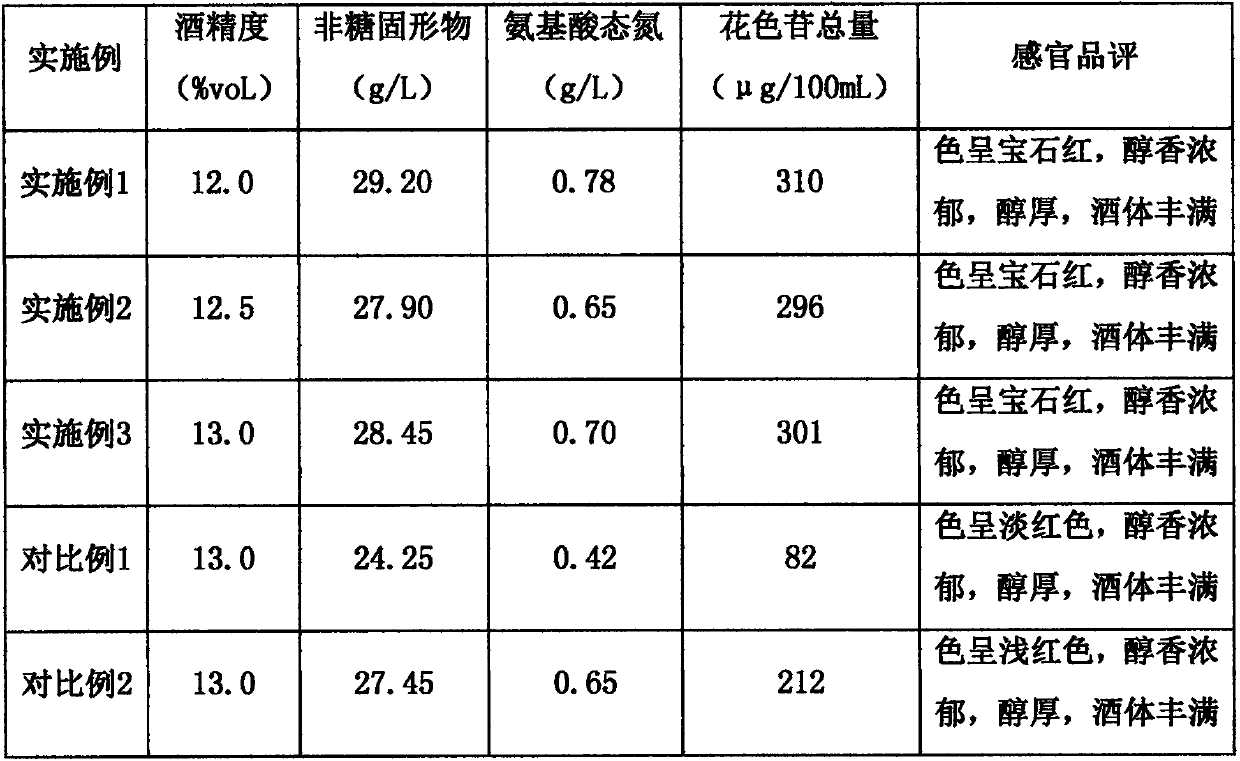

Examples

Embodiment 1

[0032] A kind of production method of blueberry wine is implemented according to the following steps:

[0033] (1) Raw material handling

[0034] (1.1) Blueberry pretreatment: take 4kg of blueberries, wash them with water, drain them, and use a press to separate them to obtain 2.5kg of blueberry juice and 1.5kg of pomace, and add food-grade 6% sulfurous acid 130ppm to the blueberry juice and pomace respectively ;

[0035](1.2) Pretreatment of black rice and fragrant rice: mix black rice and fragrant rice at a mass ratio of 1:0.5, then mix 1kg of the mixture of black rice and fragrant rice with water according to the ratio of material to liquid 60g:100mL, black rice and fragrant rice After soaking, separate and wash from the soaking water, drain the rice for later use, collect rice soaking water and rice washing water for later use as material A, material A is rich in anthocyanins, amino acids and other nutrients;

[0036] (2) Enzymolysis

[0037] (2.1) Mixed enzymolysis of ...

Embodiment 2

[0046] A kind of production method of blueberry wine is implemented according to the following steps:

[0047] (1) Raw material handling

[0048] (1.1) Blueberry pretreatment: take 4kg of blueberries, wash them with water, drain them, and use a press to separate them to obtain 2.4kg of blueberries and 1.6kg of pomace, and add food-grade 6% sulfurous acid 130ppm to the blueberry juice and pomace respectively;

[0049] (1.2) Pretreatment of black rice and fragrant rice: mix black rice and fragrant rice at a mass ratio of 1:0.5, then mix 1kg of the mixture of black rice and fragrant rice with water according to the ratio of material to liquid 60g:100mL, black rice and fragrant rice After soaking, separate and wash from the soaking water, drain the rice for later use, collect rice soaking water and rice washing water for later use as material A, material A is rich in anthocyanins, amino acids and other nutrients;

[0050] (2) Enzymolysis

[0051] (2.1) Mixed enzymolysis of pomac...

Embodiment 3

[0060] A kind of production method of blueberry wine is implemented according to the following steps:

[0061] (1) Raw material handling

[0062] (1.1) Blueberry pretreatment: Take 4kg of blueberries, wash them with water, drain them, and use a squeezer to separate them to obtain 2.3kg of blueberry juice and 1.7kg of pomace, and add food-grade 6% sulfurous acid 130ppm to the blueberry juice and pomace respectively ;

[0063] (1.2) Pretreatment of black rice and fragrant rice: mix black rice and fragrant rice at a mass ratio of 1:0.5, then mix 1kg of the mixture of black rice and fragrant rice with water according to the ratio of material to liquid 60g:100mL, black rice and fragrant rice After soaking, separate and wash from the soaking water, drain the rice for later use, collect rice soaking water and rice washing water for later use as material A, material A is rich in anthocyanins, amino acids and other nutrients;

[0064] (2) Enzymolysis

[0065] (2.1) Mixed enzymolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com