Self-leveling and low self-shrinkage ultra-high performance concrete composition

A concrete composition, ultra-high-performance technology, applied in the field of concrete, can solve the problems of small self-shrinkage value, reduce the early stress concentration of components, etc., and achieve the effects of low cracking risk, ultra-high ultra-high strength, and high system density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

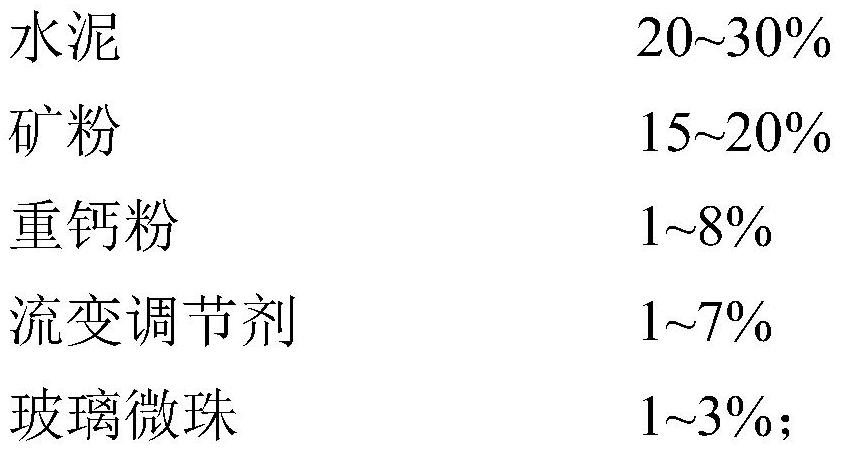

[0072] In this embodiment, a self-leveling low self-shrinkage ultra-high performance concrete composition, its raw material components are as follows:

[0073]

Embodiment 2

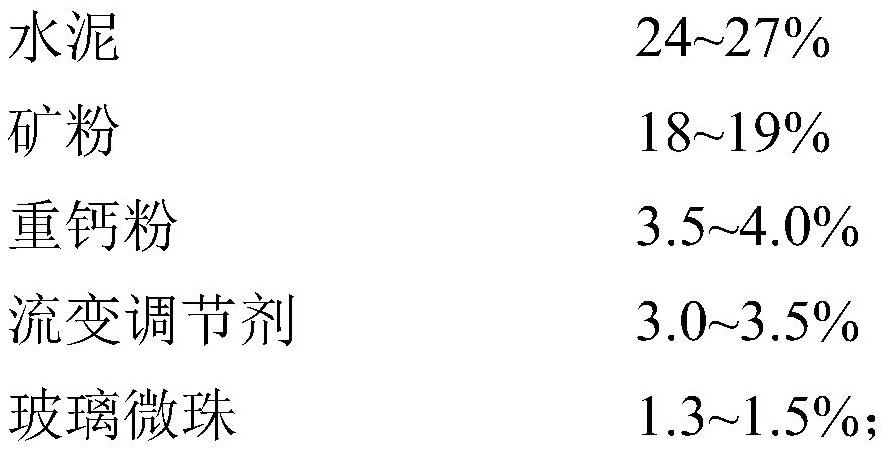

[0075] In this embodiment, a self-leveling low self-shrinkage ultra-high performance concrete composition, its raw material components are as follows:

[0076]

Embodiment 3

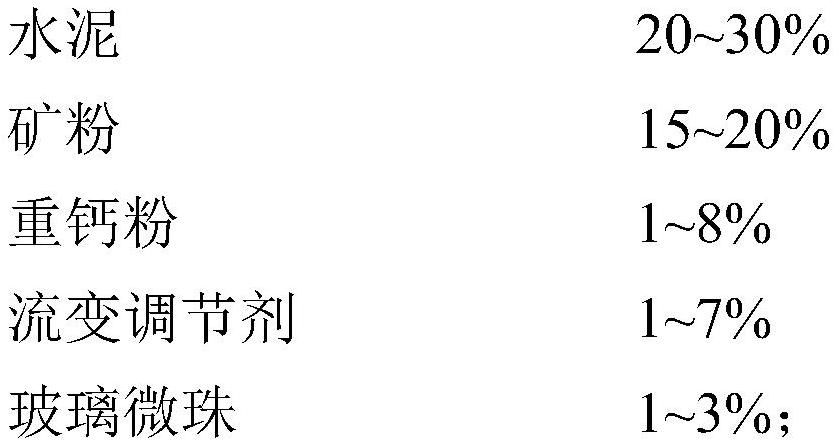

[0078] In this embodiment, a self-leveling low self-shrinkage ultra-high performance concrete composition, its raw material components are as follows:

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com