Dynamic groove bearing comprising porous lubricant reservoir

A technology of bearings and grooves, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of differences, abnormal operation of grooved bearings, differences, etc., and achieve the effect of easy setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

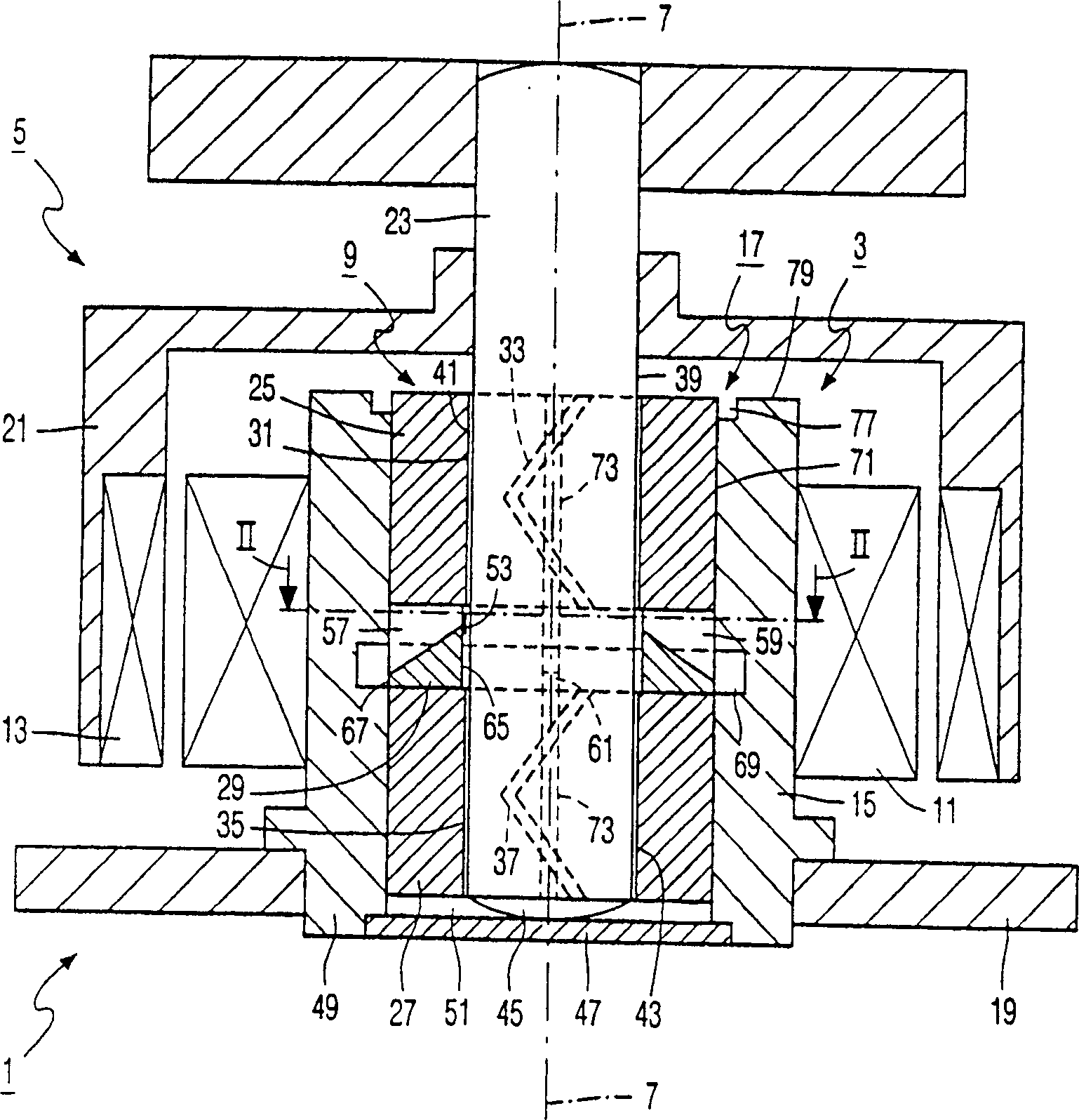

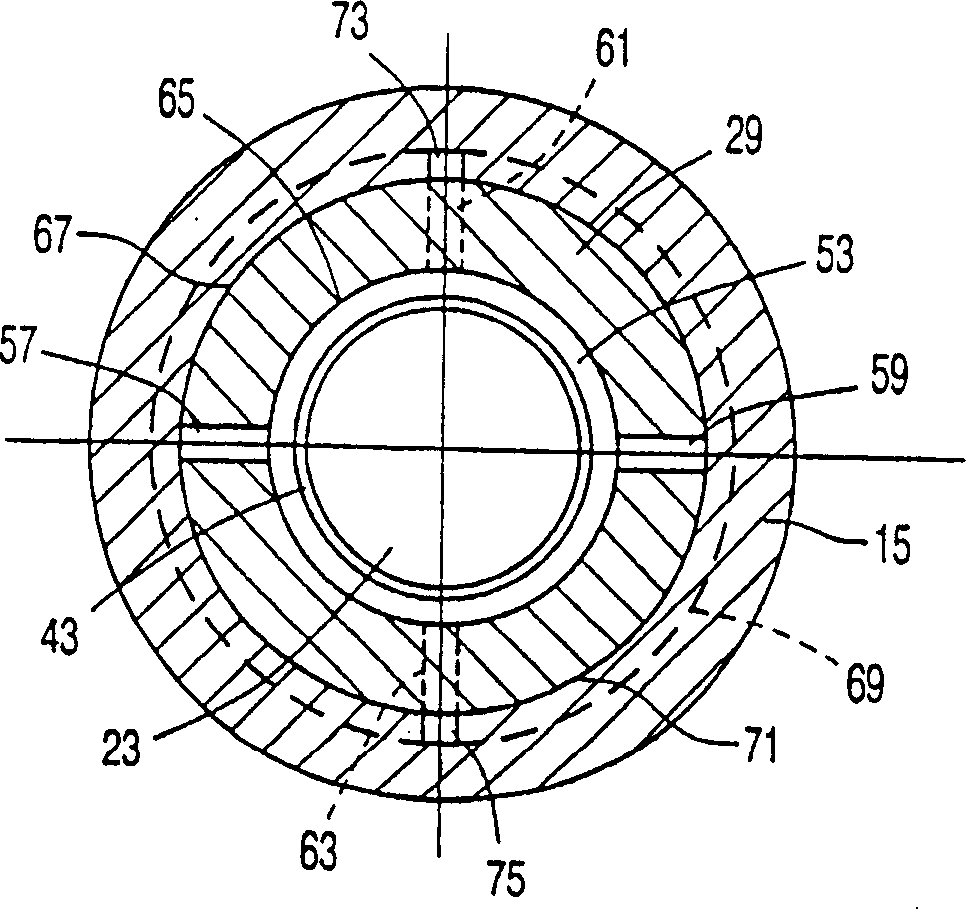

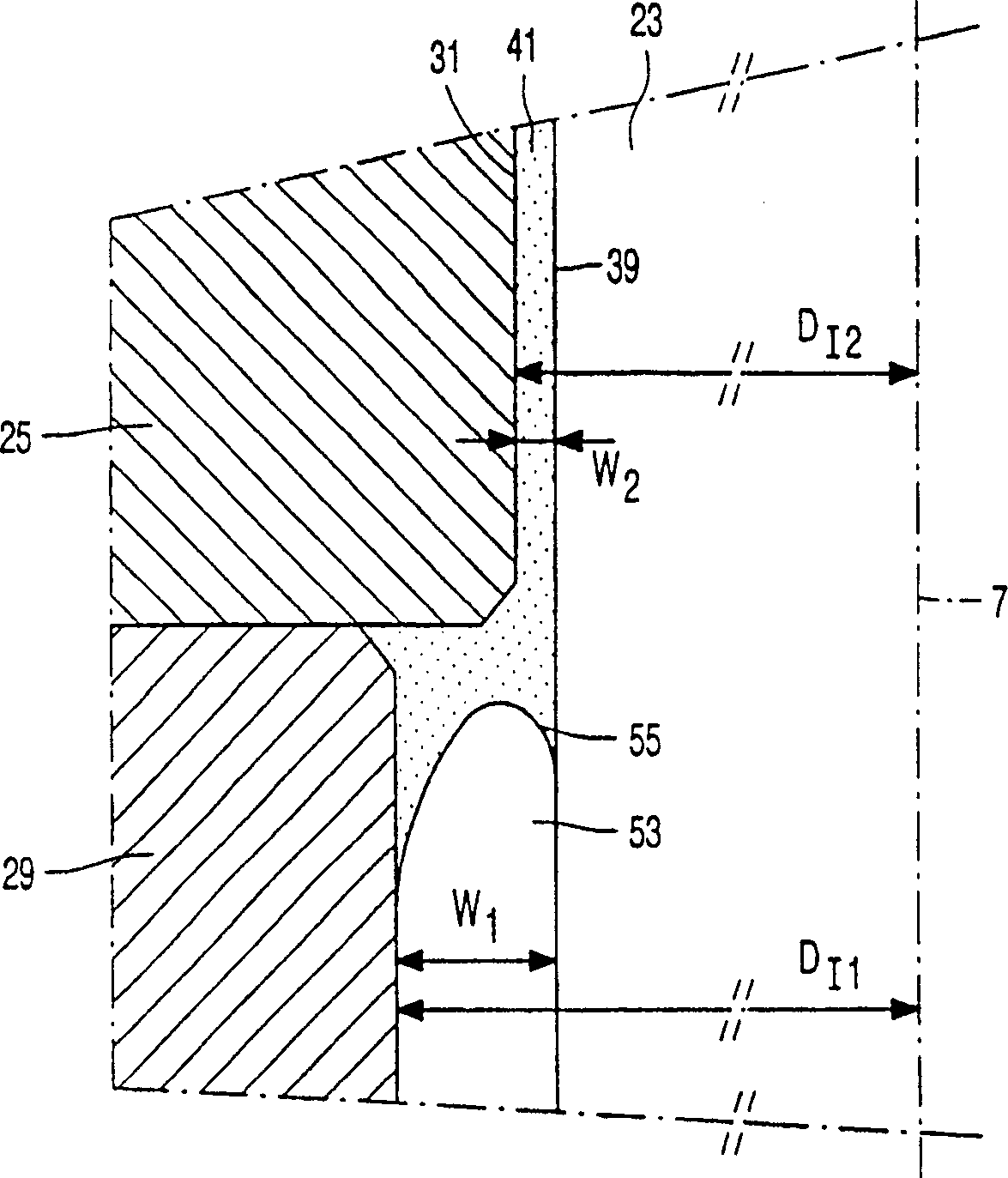

[0022] figure 1 Schematically shows an electric motor 1 according to the invention comprising a stator 3 and a rotor 5 mounted relative to the stator 3 such that the rotor can rotate relative to an axis of rotation 7 via a hydrodynamic grooved bearing 9 according to the invention . Stator 3 contains an electric coil system 11, which coil system in figure 1 is only schematically shown in , while the rotor 5 comprises a permanent magnet system 13 cooperating with an electric coil system 11, in figure 1 is only shown schematically. The electric coil system 11 is fixed to a bush-type bearing housing 15 which forms part of the outer bearing part 17 of the dynamic pressure grooved bearing 9 and which is fixed to the stationary base plate 19 of the electric motor 1 . The permanent magnet system 13 is fixed on an annular magnet support frame 21 which is fixed on a steel shaft 23 . Said shaft 23 forms the inner bearing part of the dynamic pressure grooved bearing 9 and its center l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com