Method for producing a textile sensor

一种温度传感器、织物的技术,应用在传感器、纺织品和造纸、仪器等方向,能够解决连接困难、线破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

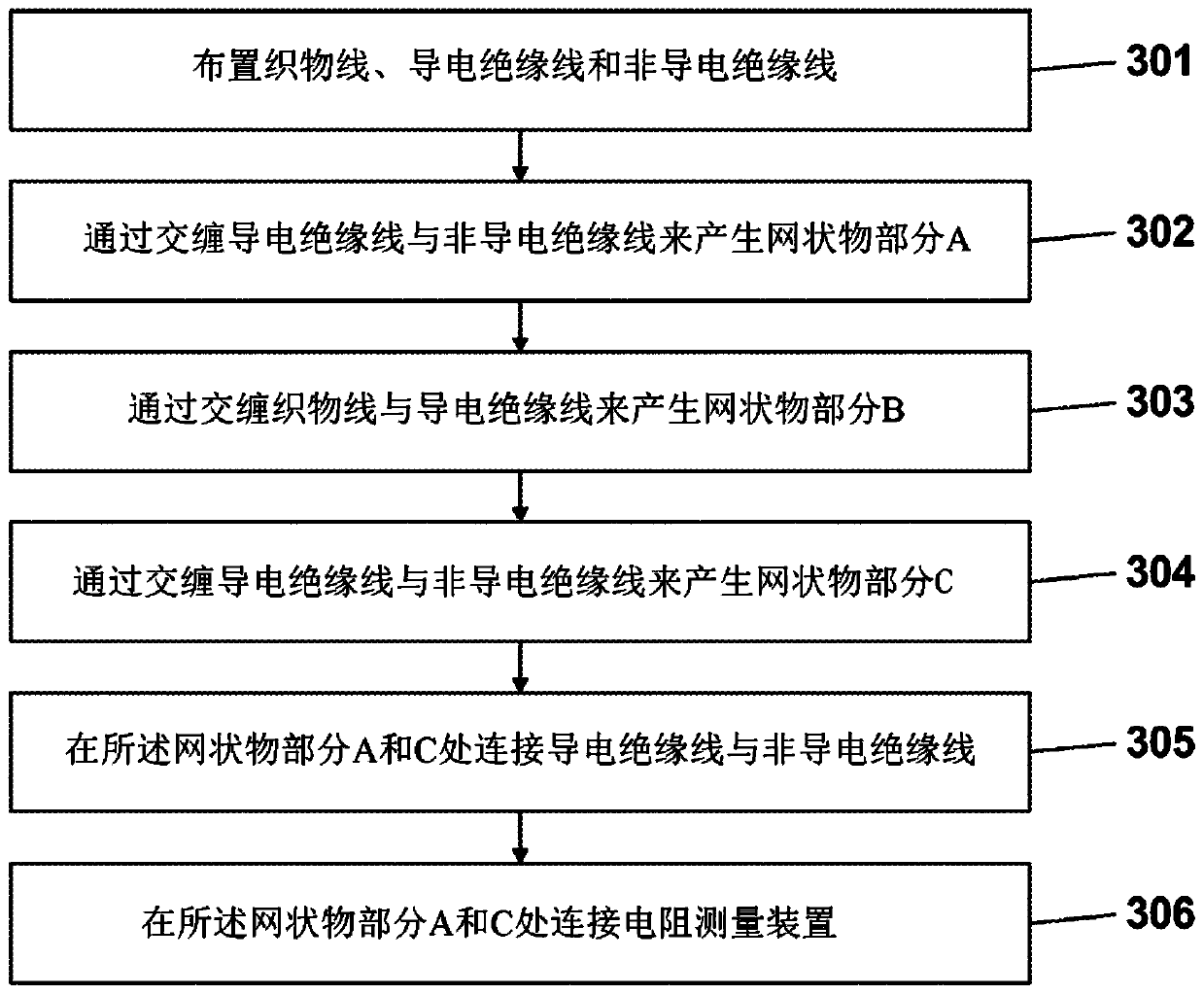

[0076] exist figure 2 The generation according to the present invention is schematically shown in Figure 4 The method steps necessary for the fabric temperature sensor 100.

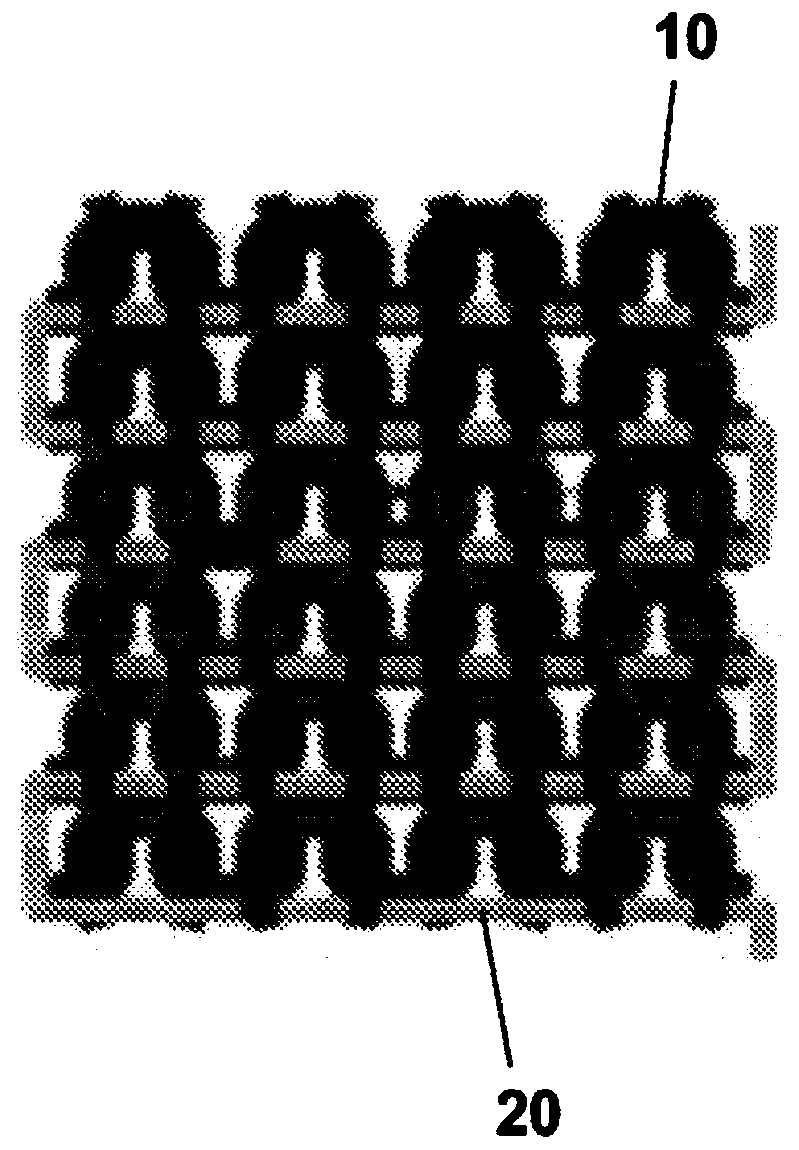

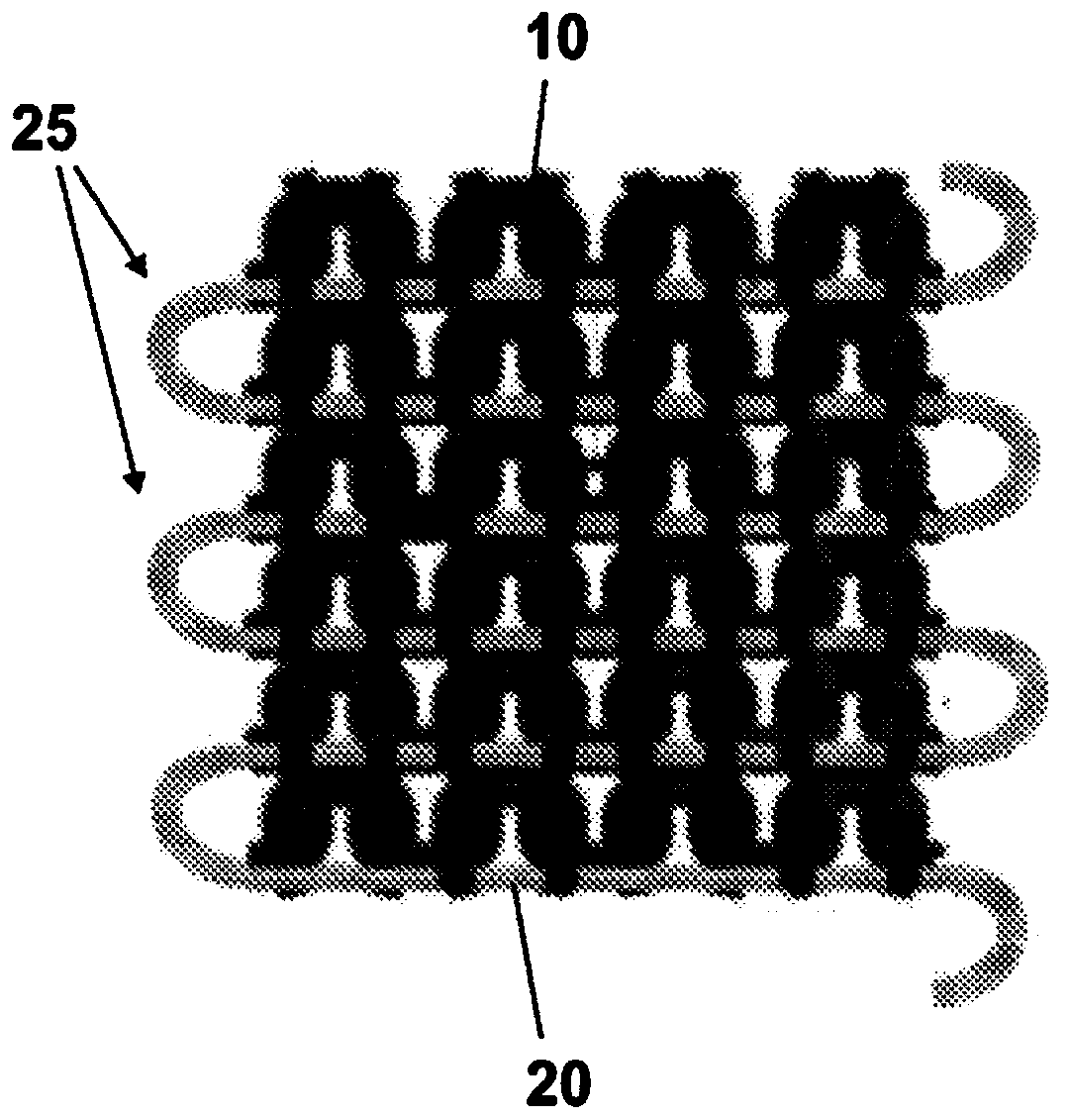

[0077] Specifically, in a preliminary step [301] of weaving threads 110, electrically conductive insulating threads 120 and non-conductive insulating threads are arranged on respective thread guides of the linear knitting machine. The conductive insulating wire 120 may be, for example, an enamelled copper wire, and the non-conductive insulating wire may be, for example, a soldered copper wire. For example, fabric thread 110 may be a polyester thread.

[0078] Then continue to intertwine the thread. refer to figure 2 with 4 , after generating parts A to C, with the following intertwining steps:

[0079] - part A: intertwining conductive insulating wire 120 with non-conductive insulating wire [302];

[0080] - Part B: intertwining non-conductive insulated wire with fabric wire 110 [303];

[0081] -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com