A method for monitoring a device for regulating the flow of a gas and a regulating system employing said method

A gas flow and gas technology, which is applied in the control/regulation system, valve operation/release device, valve device, etc., can solve the problems such as the deterioration of the performance of the pressure regulator, and achieve the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

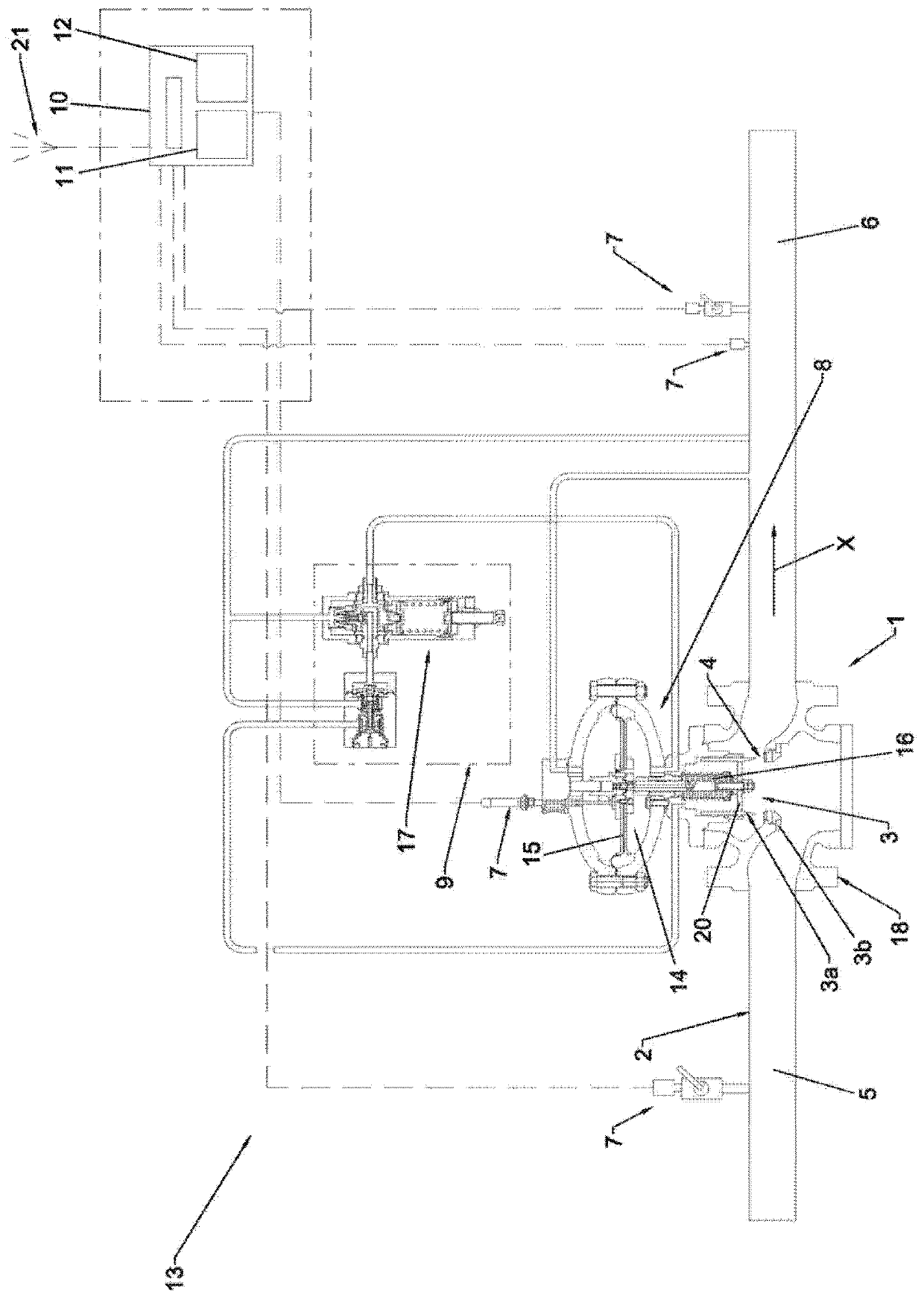

[0032] The inventive method for monitoring a device for regulating the flow of gas is described below on the basis of a regulating system in figure 1 Indicated by reference 13 in its entirety. Preferably, the above-mentioned regulating system is used in a network distributing compressed gas, in particular natural gas, in order to keep the delivery pressure of the gas to the user installation at a constant level. However, as will be apparent hereinafter, the method of the invention is equally applicable to regulating systems capable of controlling the flow of gas.

[0033] The aforementioned regulating system 13 comprises a regulating device 1 defining a flow duct 2 for conveying gas according to a predetermined direction X. Positioned in the flow duct 2 is a variable geometry closure assembly 3 which defines a restriction 4 provided with a passage area A in the flow duct 2 . In particular, the restriction 4 is delimited on two opposite sides by two corresponding sealing edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com