Ultra-high speed and high pressure precision pneumatic feed delivery valve

An ultra-high-speed, high-pressure technology, applied in valve device, valve details, climate change adaptation, etc., to achieve the effect of reducing flat cost, small opening and closing space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

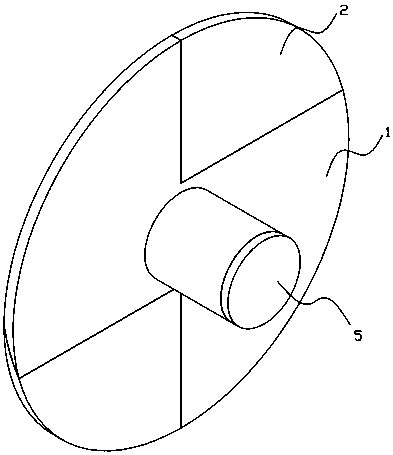

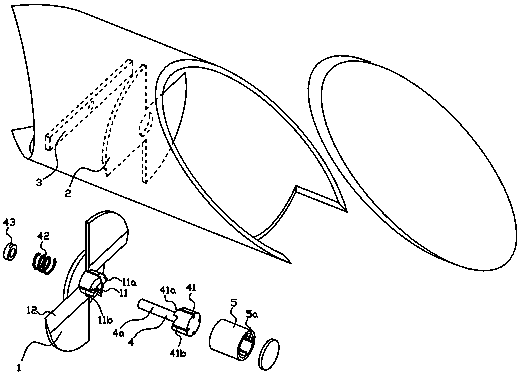

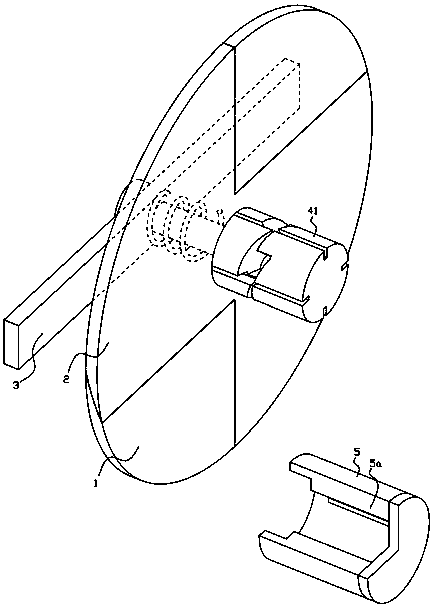

[0012] Example: refer to Figure 1 to Figure 3 , ultra-high-speed high-pressure precision pneumatic feed delivery valve, including a section of valve body, wherein: the valve body is provided with a disc-shaped fixed leaf 2 with a gap; the fixed leaf 2 is provided with a gap that can be rotated to close or open the fixed leaf 2 The rotating blade 1; near the center of the rotating blade 1 is provided with a push rod 4 that can push the rotating blade 1 to rotate. The close rotation of the rotating blade 1 and the fixed blade 2 cooperate with each other, and the pushing rod 4 is pushed in the radial direction, so that the rotating blade 1 can be switched between open and closed through a single rotation of a certain angle in one direction. Through the intelligent self-propelled equipment walking in the main pipeline, the valve is opened on demand, so the amortized cost of the pneumatic conveying valve can be greatly reduced by adopting this design. Near the center of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com