A Sealing Structure of Large Size Microwave Output Window

A technology of large size and connection structure, applied in the field of microwave output window sealing, can solve the problems of difficult to guarantee the yield, high requirements for the gap between the window and the copper ring, achieve high welding yield, reduce assembly gap and welding process requirements, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

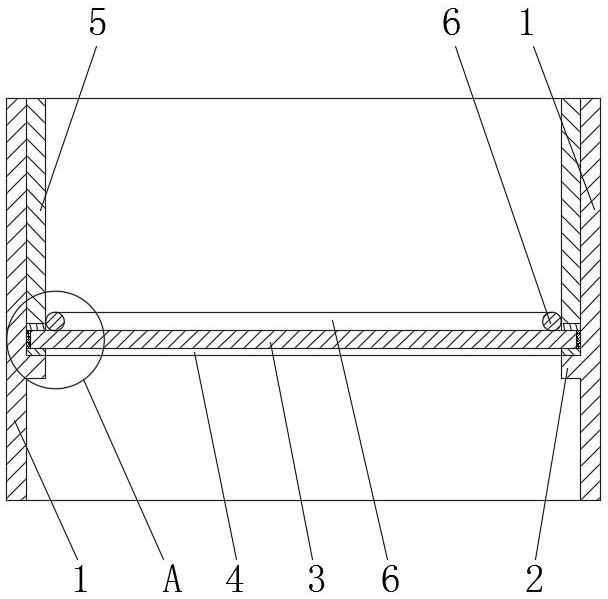

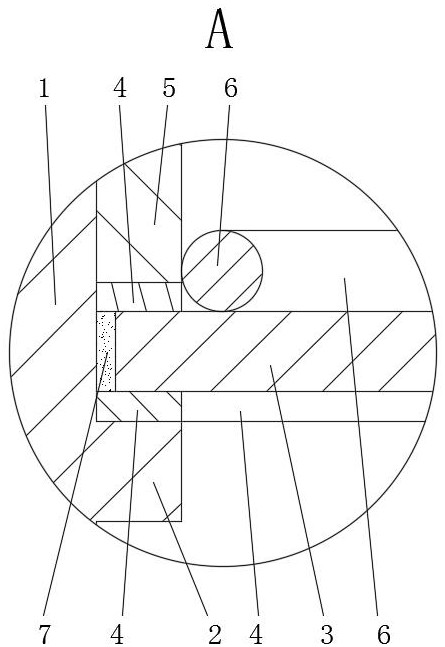

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 and 2 As shown, a sealing structure of a large-sized microwave output window includes a basic copper ring 1 with an annular mounting boss 2 inside the basic copper ring 1, and a disc-shaped microwave output window 3 is set on the annular mounting boss 2 Above, the specific material of the microwave output window 3 is sapphire, and an annular solder sheet 4 is arranged between the upper surface of the annular mounting boss 2 and the lower surface of the microwave output window 3, and the annular solder sheet 4 is specifically a silver-copper-titanium solder sheet , and realize the sealing and fixing between the upper surface of the annular mounting boss 2 and the lower surface of the microwave output window 3 through the annular solder sheet 4 .

[0021] Further, an additional copper ring 5 is set inside the basic copper ring 1, the outer diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com