A method of using liquid crystallized mxene to construct a three-dimensional mxene array and a three-dimensional mxene array

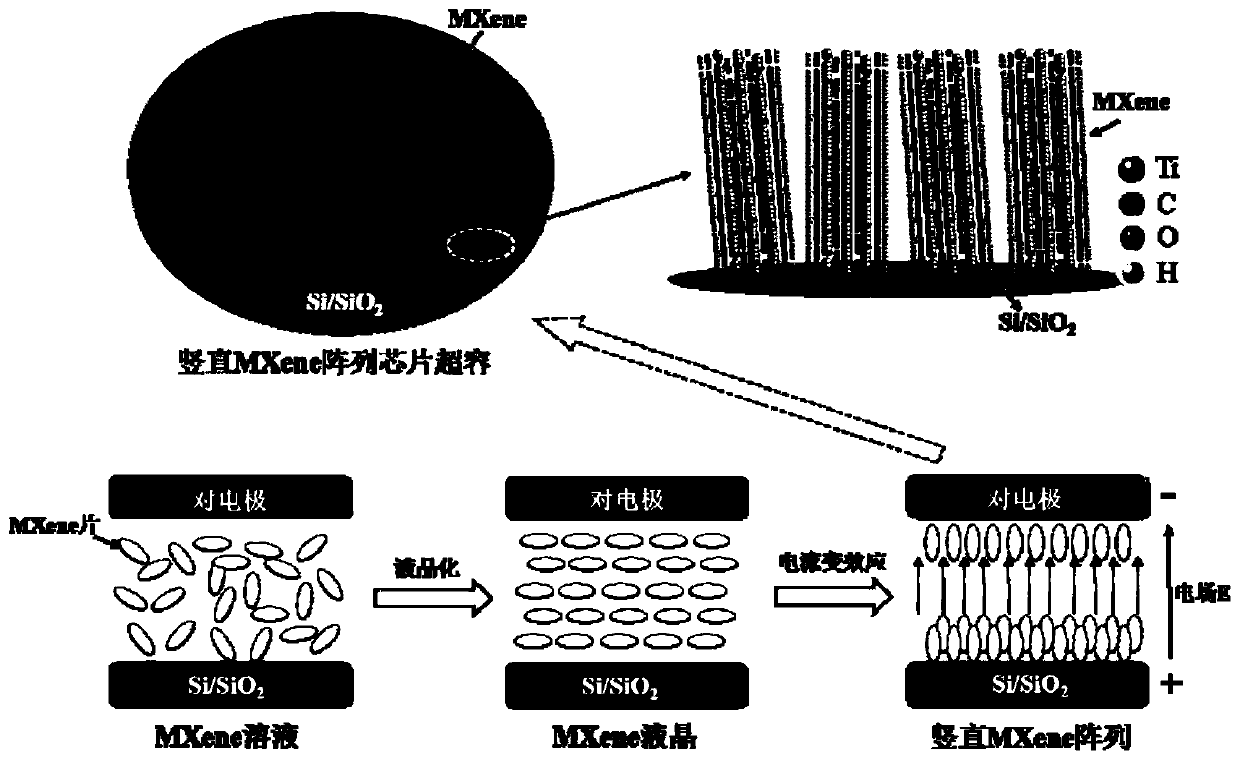

A liquid crystal, three-dimensional technology, applied in the field of electrochemistry, can solve problems such as the complexity of the three-dimensional Mxene array method, and achieve the effect of solving the random orientation of the pore structure, suitable for large-scale production, and good orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] S1, preparation of MXene colloidal solution

[0048] Add 30mL of 6mol / L HCl into 1.3g LiF, mix well, weigh 1.2g of Ti 3 AlC 2 The powder was added into the mixed solution of HCl+LiF, and reacted in a water bath at 45°C for 40 hours; the reaction product was repeatedly washed and centrifuged until the pH value was close to 7, and dried in vacuum to obtain MXene powder.

[0049] Weigh 0.2 g of Mxene powder and add it to 25 ml of deionized water, sonicate for 1 h, and then centrifuge at 3500 r / min for 1 h to obtain the upper layer of Mxene colloidal solution.

[0050] S2, obtaining the liquid crystallized Mxene solution modified by sodium alginate

[0051] Weigh an appropriate amount of sodium alginate powder and add it to the Mxene colloidal solution prepared in step S1, stir for 30 minutes, and then sonicate for 30 minutes to obtain a liquid crystallized Mxene solution modified by sodium alginate. Wherein, the mass ratio of MXene powder to sodium alginate is 1:3.

[...

Embodiment 2

[0057] A method for constructing a three-dimensional MXene array by using liquid crystallized MXene provided in this embodiment is basically the same as the method for constructing a three-dimensional MXene array by using liquid crystallized MXene provided in Example 1. The difference is that in this embodiment, The mass ratio of MXene powder to sodium alginate is 1:2.

[0058] A three-dimensional MXene array is prepared by using liquid crystallized MXene to construct a three-dimensional MXene array in this embodiment.

Embodiment 3

[0060] A method for constructing a three-dimensional MXene array by using liquid crystallized MXene provided in this embodiment is basically the same as the method for constructing a three-dimensional MXene array by using liquid crystallized MXene provided in Example 1. The difference is that in this embodiment, The mass ratio of MXene powder to sodium alginate is 1:1.

[0061] A three-dimensional MXene array is prepared by using liquid crystallized MXene to construct a three-dimensional MXene array in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com