Online specific gravity measuring system of coke oven gas

A coke oven gas and measuring system technology, applied in the direction of specific gravity measurement, measuring devices, instruments, etc., can solve the problems of not being able to adapt to the situation of automatic high-efficiency production, time-consuming and laborious, slow response speed, etc., to improve the market competitiveness of products , Easy assembly and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

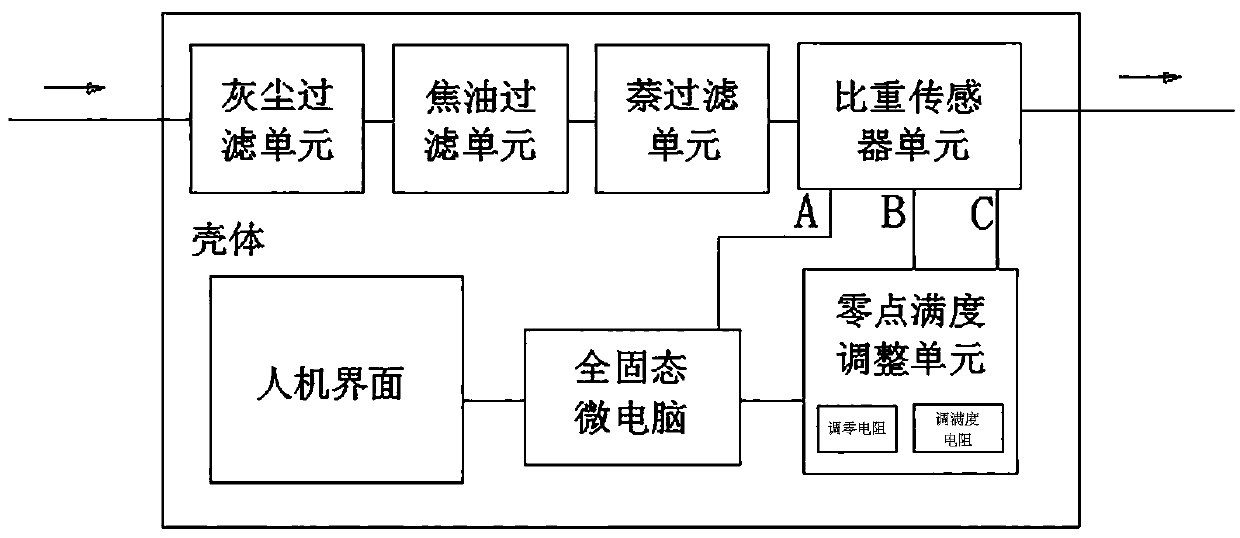

[0027] See figure 1 , is a schematic block diagram of an embodiment of the coke oven gas online specific gravity measurement system of the present invention. In the housing, the dust filter unit, the tar filter unit, the naphthalene filter unit and the specific gravity sensor unit are sequentially connected by pipelines according to the process sequence, and the dust filter unit The gas inlet port is connected to the gas inlet pipe on the casing, the gas outlet port of the specific gravity sensor is connected to the gas outlet pipe on the casing, the output port A of the specific gravity sensor unit is connected to the intelligent calibration controller, and the output port B and output port C are respectively connected to the zero full The zero-point full-scale adjustment unit is electrically connected to the intelligent calibration controller, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com