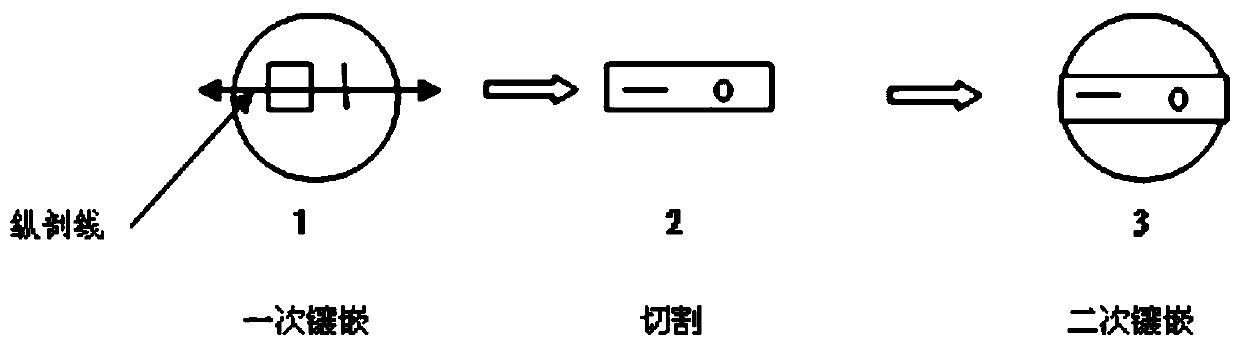

Inlaying method for products having diameter or thickness less than 2mm

A product, thermal mounting technology, applied in the field of mounting, can solve problems such as sample deflection, inability to accurately test and analyze, failure analysis of samples and internal organizational structure morphology, etc., to achieve accurate analysis data and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides an inlay method suitable for products with a diameter or thickness less than 2mm, which specifically includes the following steps:

[0031] (1) Choose the mosaic method according to the product requirements, such as semiconductors, mild steel, etc., which will be damaged when heated, choose cold mosaic, general steel, etc. choose hot mosaic, and choose according to the needs of the product;

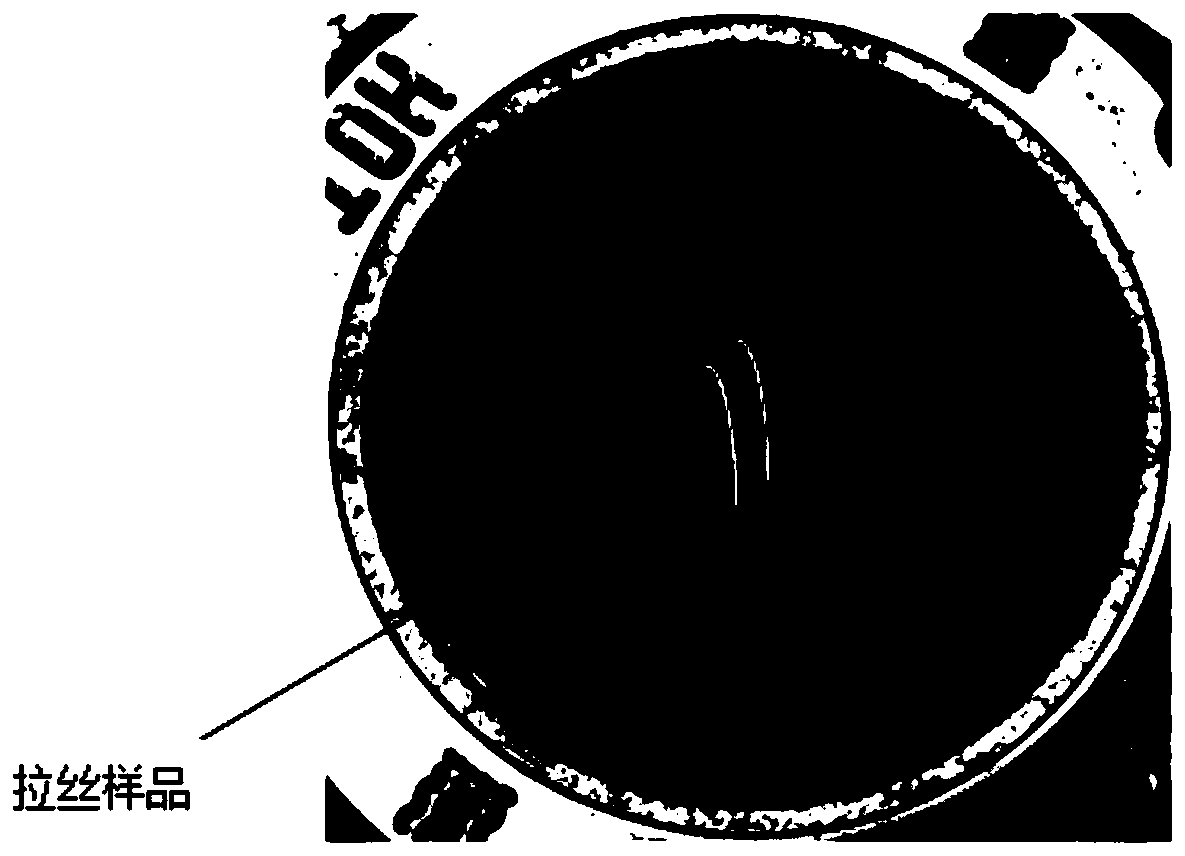

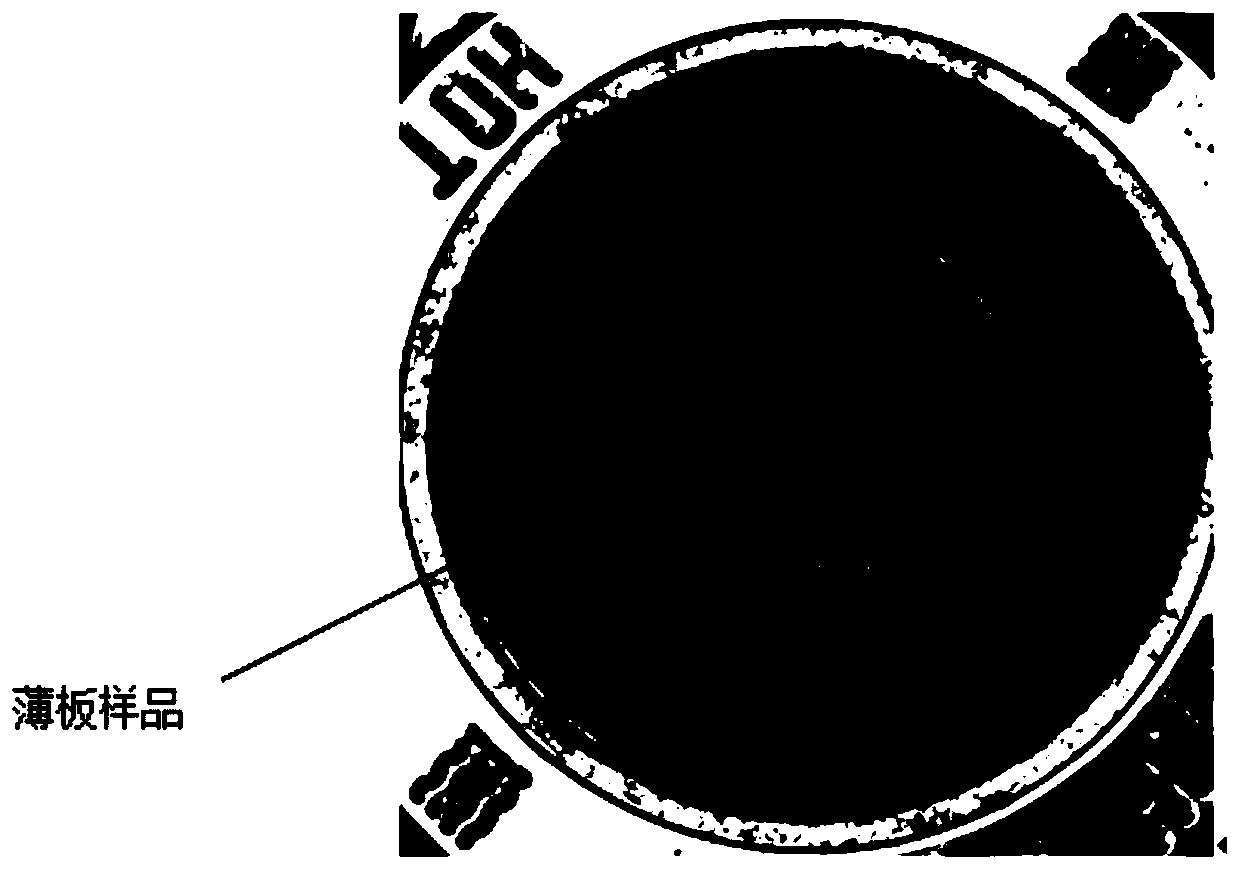

[0032] (2) Spread the prepared 0.85mm sample sheet and the 0.3mm diameter wire-drawn sample in a metallographic mounting machine with an inner mold of 30mm preheated for 5 minutes, and then put 7-10g of thermal mounting powder (the thermal mounting powder is phenolic The mixture of plastic powder, bakelite powder and electric jade powder, hot mosaic powder is already in good proportion when you buy it, and the hot mosaic powder with such ingredients in it is used) to form a 5mm high sample, close the lid, and apply pressure , 150 degrees heat preservation f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com