Dual-stress concentration structure micro pressure sensor core body and manufacturing method thereof

A micro-pressure sensor and stress concentration technology, which is applied in the measurement of the property force of piezoelectric resistance materials, etc., can solve the problem of unsolved sensitivity and linearity, sensitivity and frequency response characteristics, secondary stress concentration effect is general, influence Effective control of linearity and other issues to achieve mass production, improve dynamic response characteristics, and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

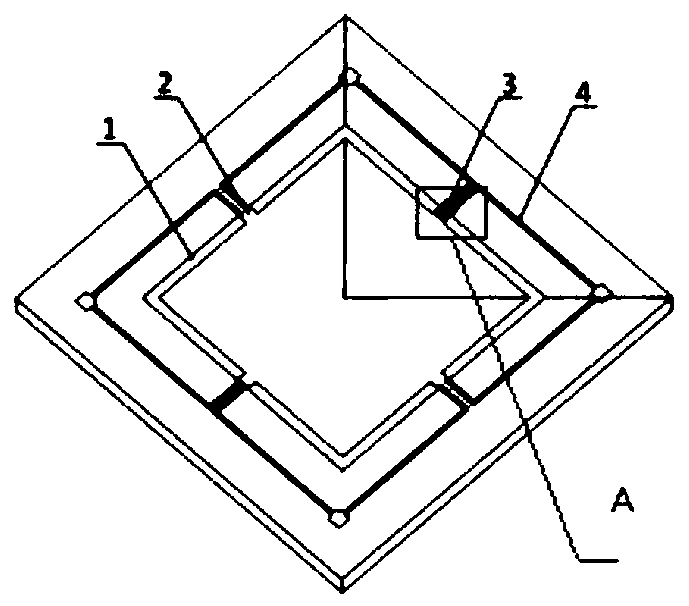

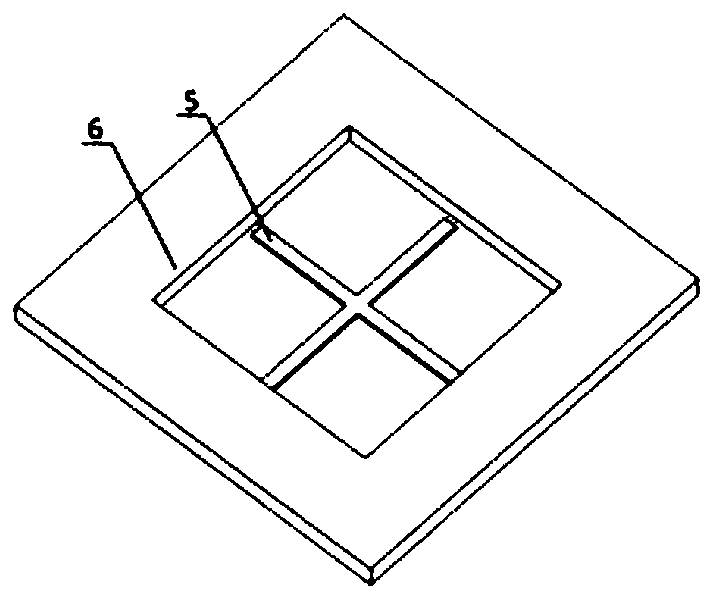

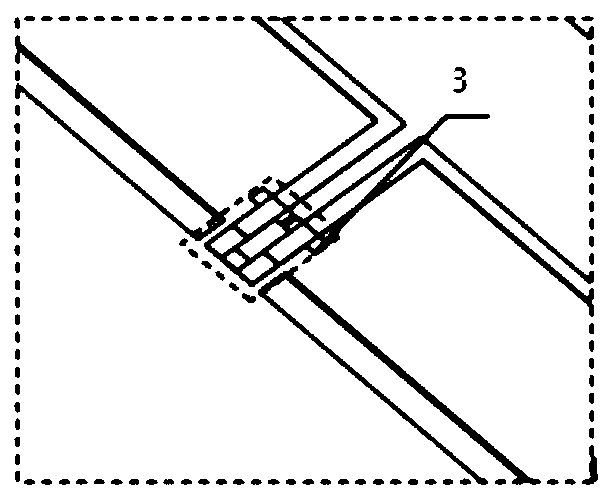

[0044] A core body of a micro-pressure sensor with a double stress concentration structure includes a substrate 6, and the core body uses N-type 100 crystal orientation SOI as the material of the substrate 6. And the diaphragm provided in the middle of the base 6, the upper surface of the diaphragm is evenly provided with more than two discontinuous grooves 1 in the circumferential direction, ribs 2 are formed between the ends of adjacent grooves 1, and the ribs 2 are arranged symmetrically on the upper surface of the diaphragm. A piezoresistor strip 3 is arranged at the stress concentration place of the rib 2, and the piezoresistor strip 3 is connected to form a Wheatstone bridge through metal leads. A protruding rigid structure 5 is formed on the lower surface of the diaphragm, and the center of the rigid structure 5 passes through the center of the back of the core to reduce the displacement of the diaphragm center; the outer end surface of the rigid structure 5 is in conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com