Molding equipment automatic reset calibration device of pulp molding product

A molding equipment, automatic reset technology, applied in measuring devices, optical devices, textiles and papermaking, etc., to solve the problem of poor accuracy retention, easy to use, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

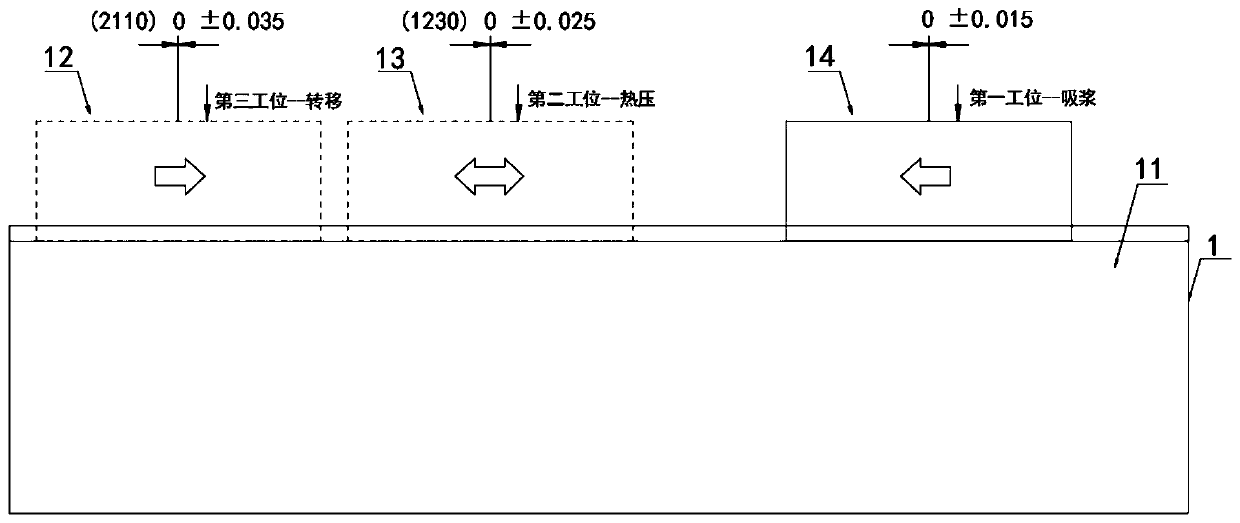

[0031] according to Figure 1-3 The shown automatic reset calibration device for molding equipment of pulp molded products includes a molding machine 1 and a grating ruler body 2, the molding machine 1 includes a machine bed 11, and a first working 12, the second station 13 and the third station 14, the first station 12, the second station 13 and the third station 14 are arranged in sequence from right to left, and the first station 12 is set There is a pulp suction mechanism for absorbing pulp, the second station 13 is provided with a heat press mechanism for hot press forming, the third station 14 is provided with a transfer mechanism for transferring finished products, and the first station A reciprocating workbench 15 is movable on the position 12, the second station 13 and the third station 14, and the front and rear sides of the reciprocating workbench 15 are provided with a drive mechanism 3, and the grating ruler body 2 includes a scale grating 21 and a grating The re...

Embodiment 2

[0034] according to figure 1 Shown is an automatic reset calibration device for molding equipment of pulp molded products. The drive mechanism 3 includes a screw rod 31 and a servo motor 32. The screw rod 31 is connected to the servo motor 32. Both ends of the screw rod 31 The bearing is fixedly connected with the machine bed 11, and the outside of the screw rod 31 is provided with a slider, and the inner wall of the slider is provided with an internal thread matched with the outer wall of the screw rod 31, and the reciprocating table 15 is fixed to the slider connect;

[0035] The top side of the machine bed 11 is fixed with a first mounting plate 4, the scale grating 21 is fixedly connected with the machine bed 11 through the first mounting plate 4, and the scale grating 21 is the same length as the machine bed 11, The indicator grating 224 is arranged parallel to the scale grating 21, and the front side of the grating reading head 22 is fixedly provided with a second mount...

Embodiment 3

[0038] The present invention also provides a method for using an automatic reset calibration device for molding equipment of pulp molded products. The specific operation steps are as follows:

[0039] Step 1. First, fix the scale grating 21 on the top side of the machine bed 11, fix the grating reading head 22 on the top side of the reciprocating workbench 15, and keep the scale grating 21 and the grating reading head 22 arranged in parallel;

[0040] Step 2: Start to use. During use, the grating ruler body 2 performs real-time monitoring to detect the linear displacement and moving speed of the reciprocating workbench 15, and sends the detection signal to the external PLC controller through the drive circuit 225. The external PLC controller Control the servo motor 32 to accurately locate the position of the reciprocating worktable 15 to achieve precise machining;

[0041] Step 3. After using for a period of time, after the servo motor 32, screw rod 31, slide rail 7 and relate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com