Lead drawing method for valve with lead falling

A valve and valve stem technology, applied in valve devices, engine components, mechanical equipment, etc., can solve problems such as low pumping efficiency, and achieve the effects of rapid pumping, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

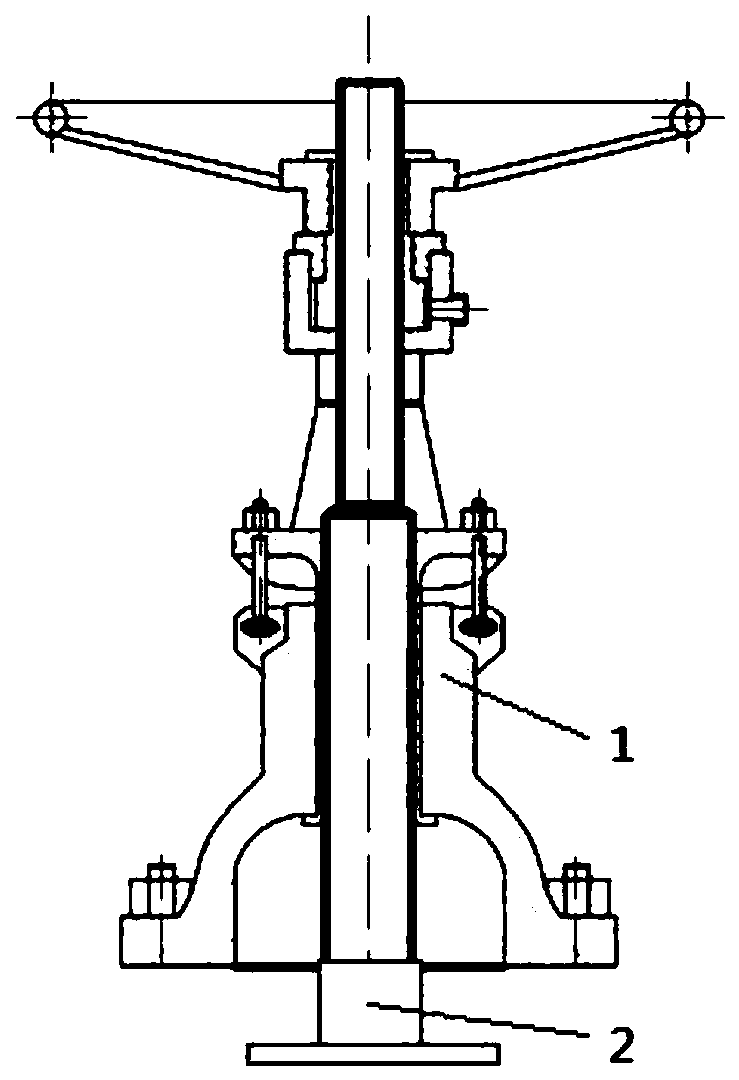

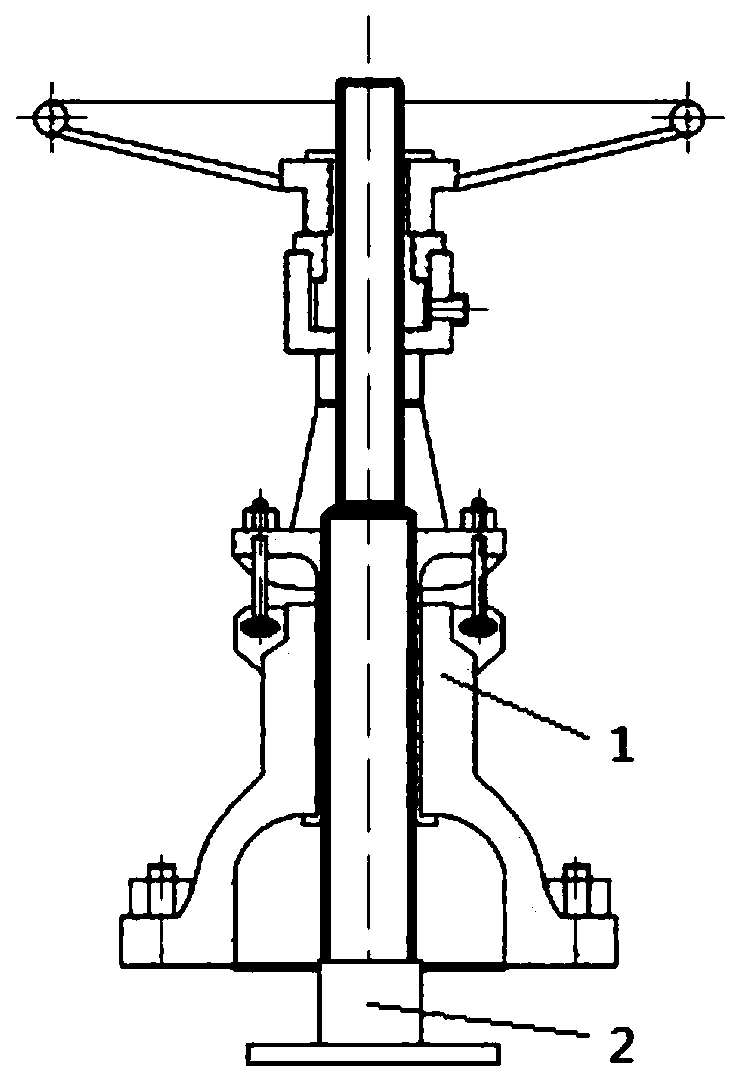

[0016] see figure 1 , a method for removing the weight of the valve, the method is: after removing the valve body part with the waste valve 1, punch a threaded hole at the bottom of the valve stem, and then install a screw 2 on the threaded hole, and install a screw 2 at the bottom of the screw 2 according to the difference of the valve Choose the gasket for the model, let the gasket hang the valve weight that has fallen off, and realize the valve weight to be pulled out.

[0017] The diameter of the threaded hole at the bottom of the valve stem of the above-mentioned valve is 12mm.

[0018] The model of the above screw 2 is M12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com