Movable grain elevator

A grain suction machine and electric motor technology, applied in the direction of conveyor, transportation and packaging, conveying bulk materials, etc., can solve the problems of wasting labor and low efficiency, and achieve the effect of saving labor and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

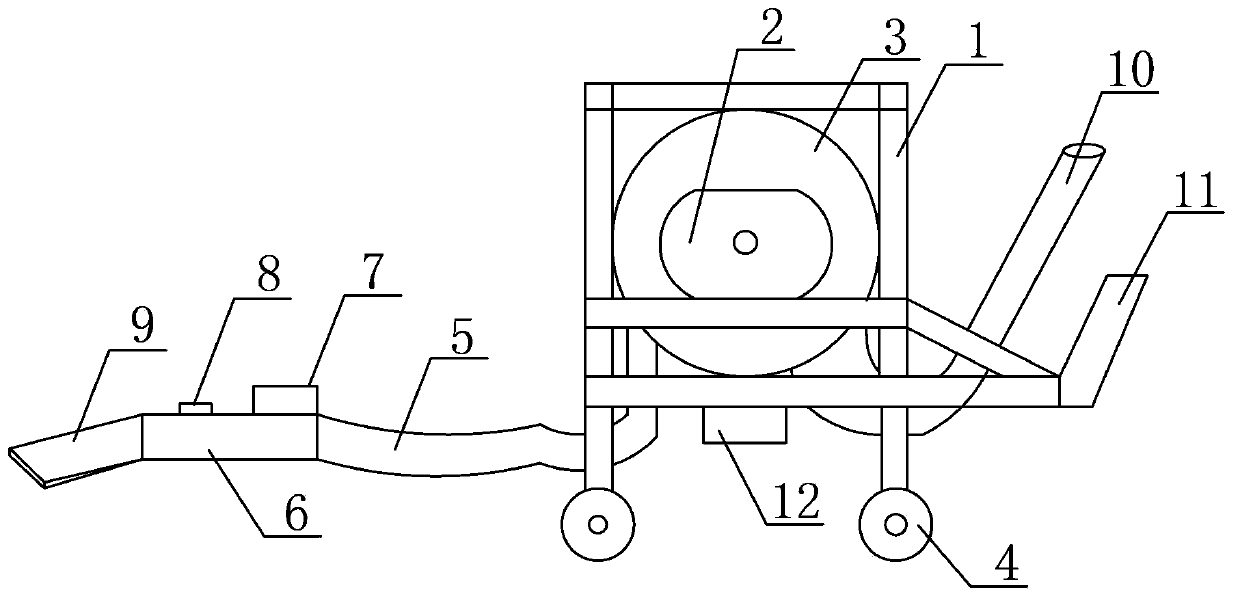

[0009] Such as figure 1 As shown, the present invention installs the motor 2 inside the support 1, the vacuum chamber 3 is installed on the motor 2 and is fixed inside the support 1, the bottom of the support 1 is equipped with a wheel 4, and the suction port of the vacuum chamber 3 is equipped with a suction pipe 5 and a suction pipe 5 The other end of the suction tube 6 is installed, and the handle 7 and the control switch 8 are respectively arranged above the suction tube 6. The other end of the suction tube 6 is provided with a suction head 9, and the grain outlet is connected with the grain output pipe 10. On the right side of the bracket 1 Cart handrail 11 is set, and distribution box 12 is installed at the bottom.

[0010] Through the above settings, when collecting grain, hold the handle 7 with one hand, and operate the control switch 8 with the other hand, the distribution box 12 supplies power to the motor 2, and the motor 2 drives the vacuum chamber 3 to run, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com