Mining system based on the mining of massive hydrate solids in the shallow surface of the ocean

A hydrate solid and shallow surface technology, applied in the direction of mining minerals, mining fluids, underwater structures, etc., can solve the problems of high local purity, shallow buried layers, blank technical equipment, etc., to reduce environmental risks and improve lift Efficiency, the effect of improving decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

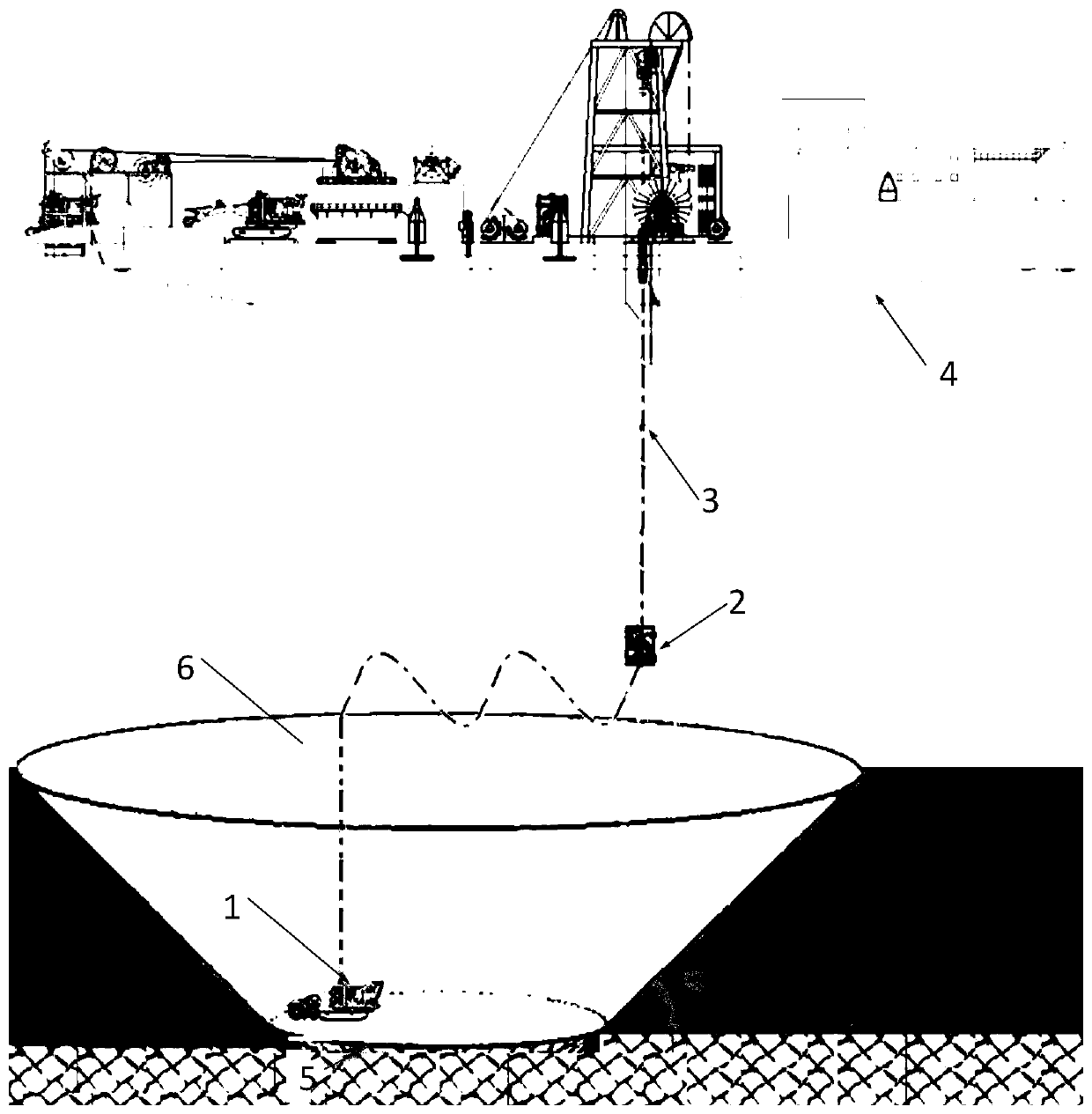

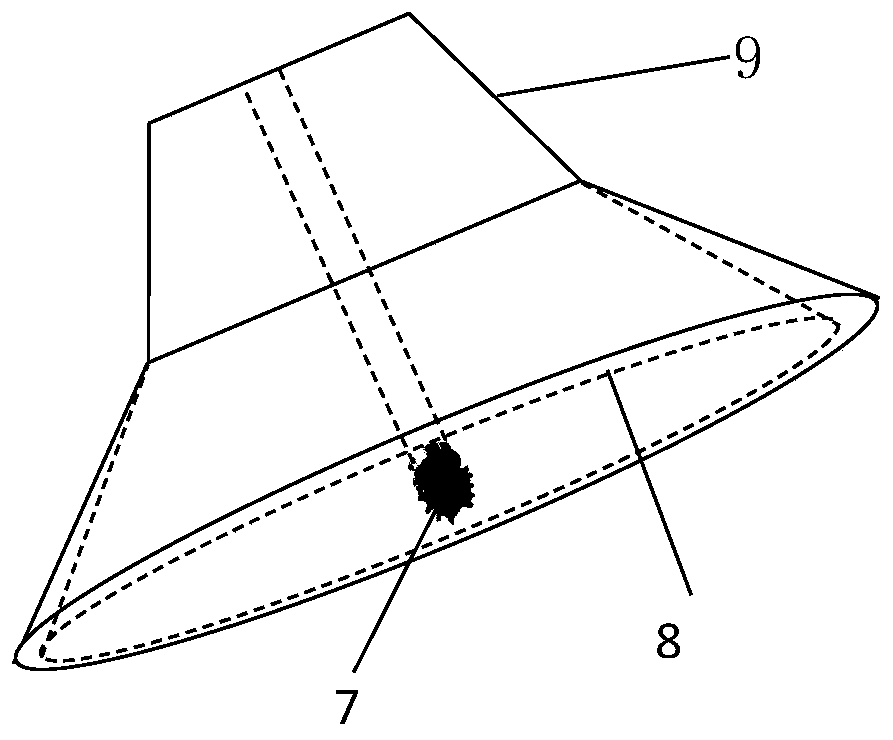

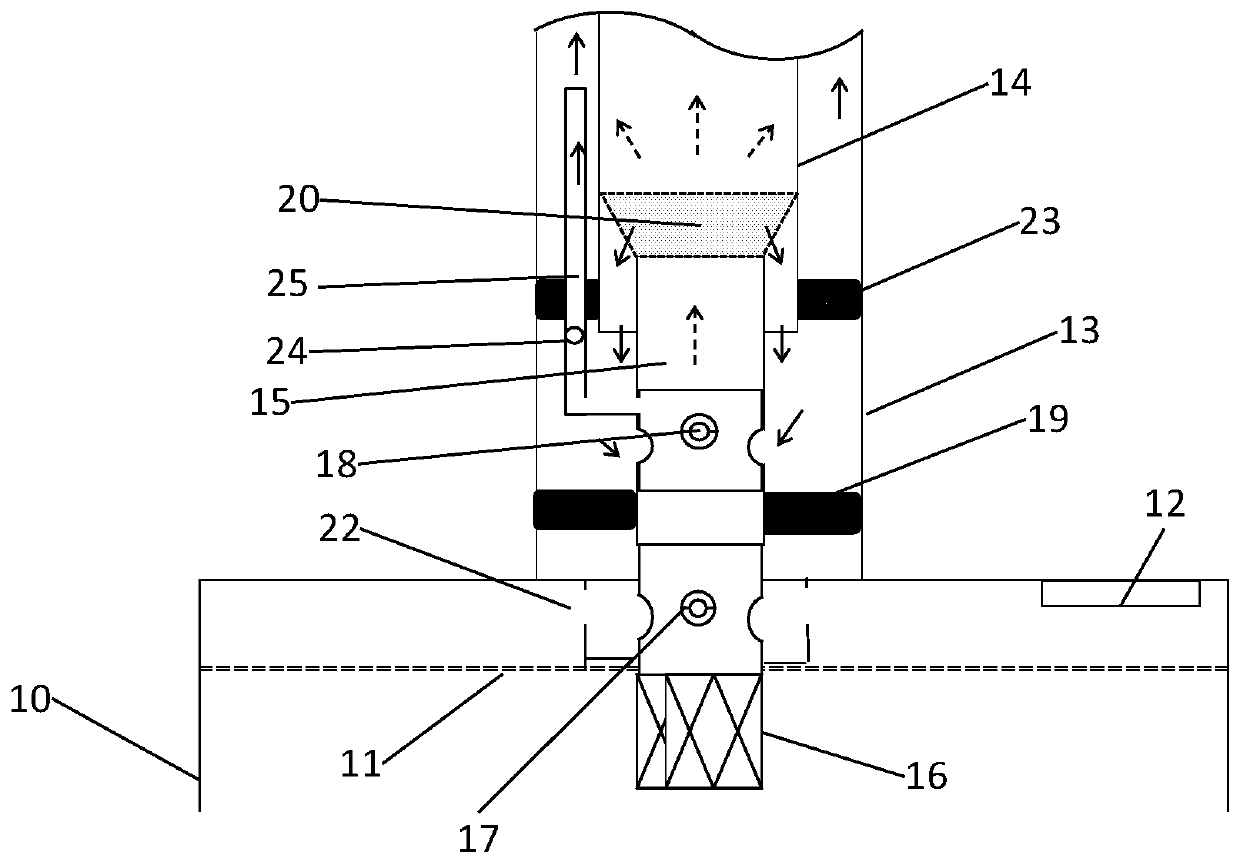

[0028] Embodiment 1, the mining system based on the mining of massive hydrate solids in the shallow surface of the ocean, such as figure 1As shown, it includes surface sediment stripping unit, massive hydrate mining unit 1, underwater relay station 2, power lift unit 3 and water surface support unit 4;

[0029] The surface sediment stripping unit is used to efficiently remove or transfer the muddy layer overlying the shallow hydrate under controllable conditions. A hinged suction stripping machine is used to strip the surface sediment (<20 meters), and the pumping The sediment pumping ability of the sand pump can transport the mixture of sediment and water to the designated position through the pipeline. In order to keep the slope of the sediment pit after stripping stable, the area after stripping is a bowl-shaped pit 6, and the slope of the pit 6 When the angle α is less than 45°, the hinged suction stripper (or seabed sediment excavator) can travel on the seabed, monitor it...

Embodiment 2

[0042] Embodiment 2, based on the mining method of the mining system based on the mining of massive hydrate solids in the shallow surface layer of the ocean described in Embodiment 1, it is basically as follows: (1) firstly use a seabed mining / excavation multi-purpose vehicle to peel off the seabed surface sediments , exposing the combustible ice ore body; (2) Then use the mining vehicle to mine massive hydrate, after desliming and crushing, and at the same time use the strong suction technology to transport the hydrate slurry to the subsea relay warehouse through the hose; (3) After stirring and standing the hydrate slurry in the intermediate tank, the sediment in the slurry and pure hydrate are separated, and the purified hydrate slurry is lifted to the sea surface by a high-pressure pump through the delivery pipeline (4) Through the three-phase separation device, the three-phase separation of gas-liquid-solid (residual clay-level suspension) is realized. After the liquid-sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com