Automatic detection equipment and an automatic detection method for a ballastless track bearing platform

A ballastless track, automatic detection technology, applied in the direction of track, track maintenance, roads, etc., can solve the problems of large waste of adjustment pads, a lot of manpower and time, and heavy re-measurement workload, etc. The effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

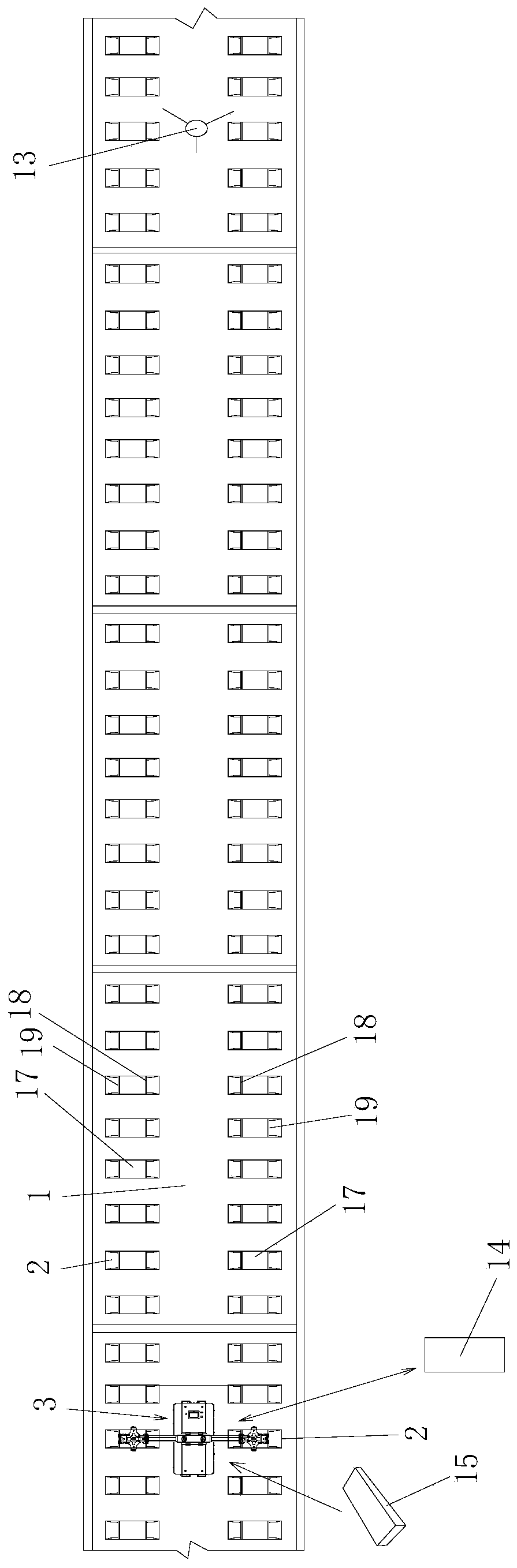

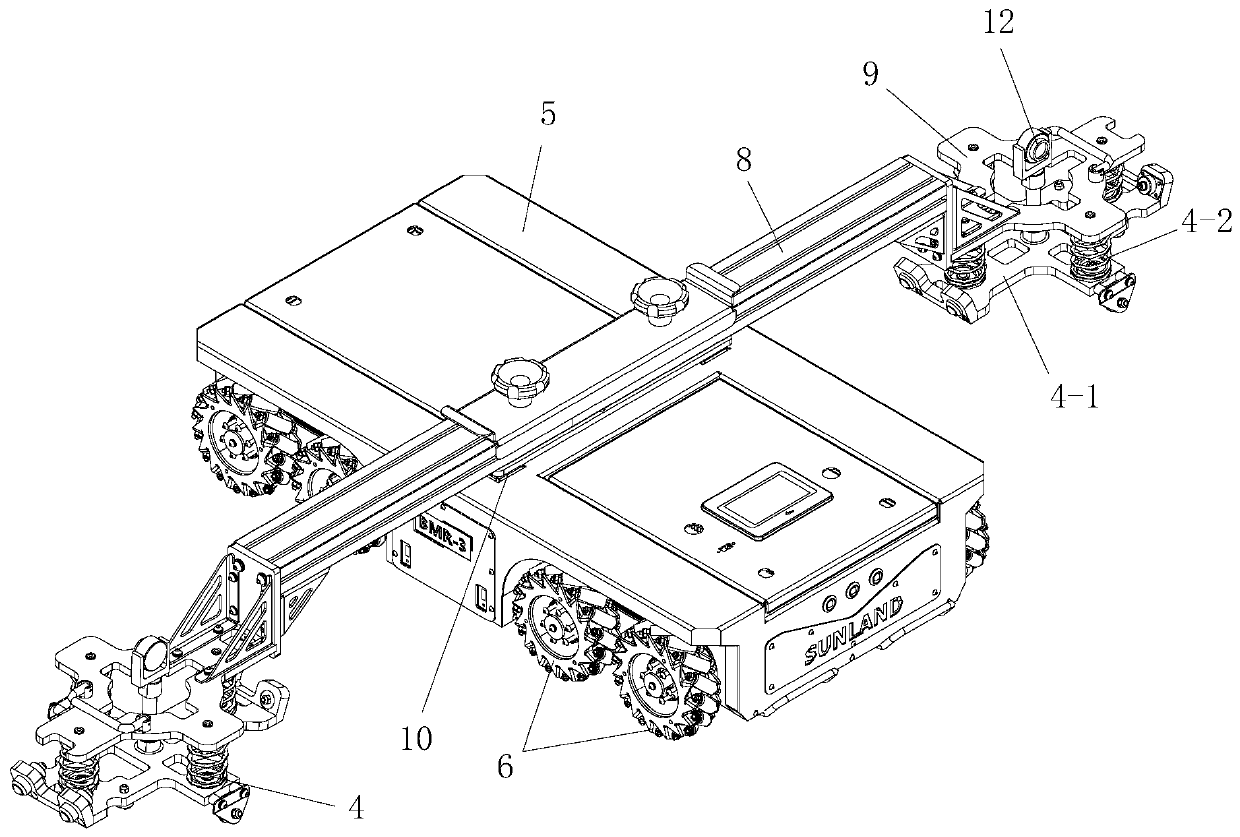

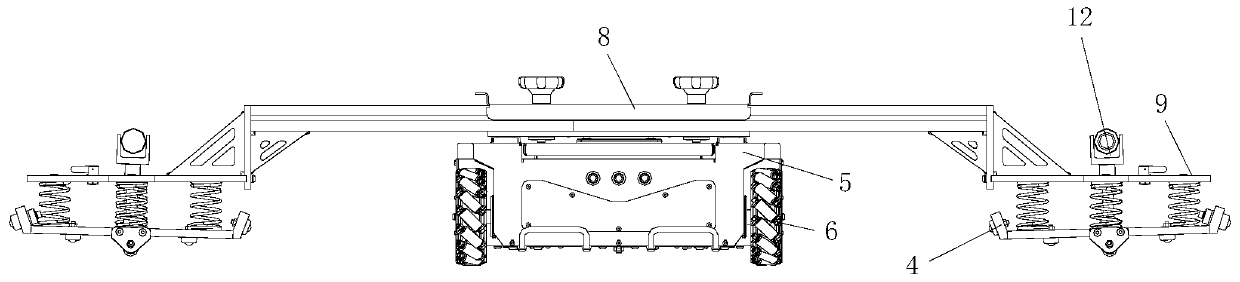

[0066] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the ballastless track bearing platform automatic detection equipment according to the present invention includes moving from back to front along the longitudinal extension direction of the ballastless track 1 to be tested and can be located on the same cross-section of the ballastless track 1 to be tested A rail platform detection robot 3 that detects synchronously with two symmetrically arranged rail platforms 2 on the left and right;

[0067] The rail platform detection robot includes a car body that can move from back to front on the ballastless track 1 to be tested and is located between two symmetrically arranged rail platforms 2 on the left and right. The clamping mold 4 that is clamped in the rail bearing groove of the rail platform 2, a mold mounting frame that is installed on the car body and supports the two clamping molds 4, and drives the mold mounting frame A liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com