A preparation for degrading pesticide residues in natural fabrics, its preparation method and application

A technology of fabrics and middle farmers, which is applied in the field of preparations for degrading pesticide residues in natural fabrics. It can solve problems such as difficulties in ethanol recovery, damage to fiber strength, and environmental pollution, and achieve good overall performance, low cost, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

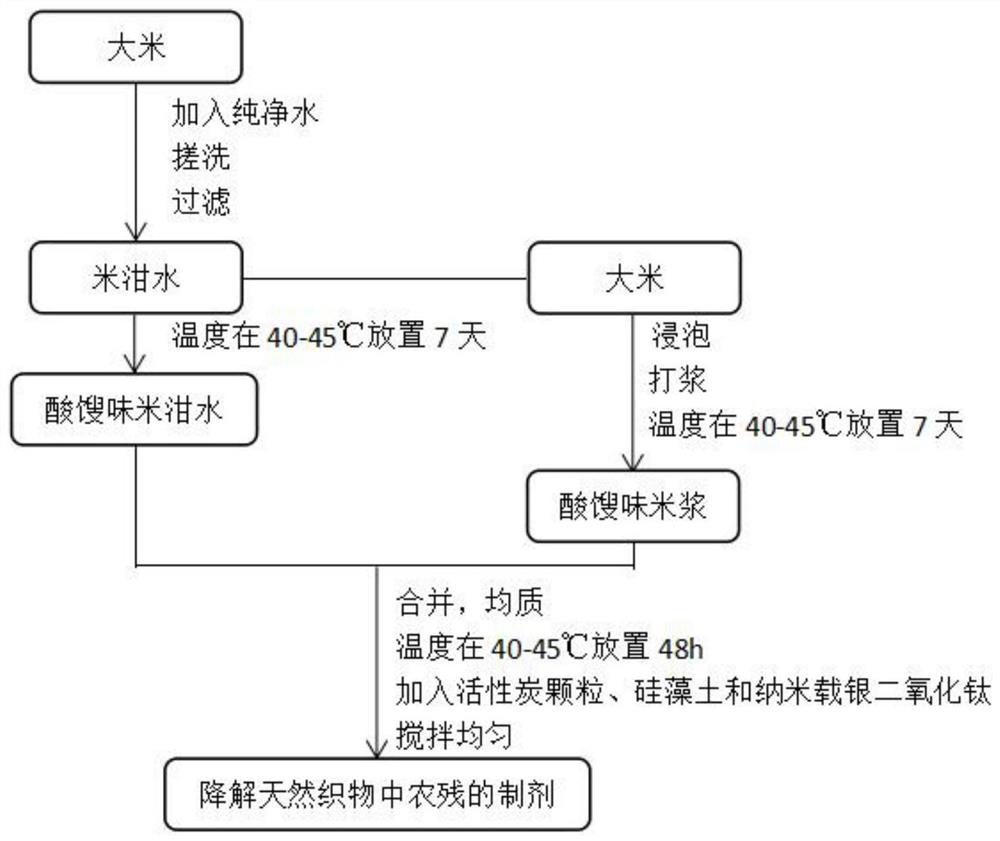

Method used

Image

Examples

Embodiment 1

[0034] Nano silver-loaded titanium dioxide is prepared by the following methods:

[0035] S1. Heat 100mL 2mol / L silver nitrate solution in a water bath to 40°C, add 0.06mol polyvinylpyrrolidone, add 0.24mol tea polyphenol while stirring, and react for 1 hour to prepare nano-Ag particles;

[0036] S2. Take 1mol Ti(OC 4 h 9 ) 4 Mix with absolute ethanol, add 0.1mol nano-Ag particles, stir evenly to make liquid A; take 50mL absolute ethanol, 30mL glacial acetic acid and 20mL distilled water, mix evenly to make liquid B; slowly pour into liquid A while stirring Add solution B dropwise, continue to stir until the solution turns into a gel, seal and age for 13 hours, put it in a drying oven for drying at a constant temperature of 80°C, take it out after it is completely dry, put it in a muffle furnace, and heat it at 6°C / h The heating rate was increased to 450°C, the calcination was continued for 2 hours, and the ball mill was taken out to obtain nanometer silver-loaded titanium ...

Embodiment 2

[0043] Nano silver-loaded titanium dioxide is prepared by the following methods:

[0044] S1. Heating the silver nitrate solution to 50° C. in a water bath, adding polyvinylpyrrolidone, adding tea polyphenols while stirring, and reacting for 2 hours to prepare nano-Ag particles;

[0045]S2. Take 1mol Ti(OC 4 h 9 ) 4 Mix with absolute ethanol, add 0.3mol nano-Ag particles, stir evenly to make liquid A; take 50mL absolute ethanol, 30mL glacial acetic acid and 20mL distilled water, mix evenly to make liquid B; slowly pour into liquid A while stirring Add liquid B dropwise, continue to stir until the solution becomes a gel, seal and age for 15 hours, put it in a drying oven for drying at a constant temperature of 80°C, take it out after it is completely dry, put it in a muffle furnace, and heat it at 6°C / h The heating rate was increased to 450°C, the calcination was continued for 2 hours, and the ball mill was taken out to obtain nanometer silver-loaded titanium dioxide.

[00...

Embodiment 3

[0052] Nano silver-loaded titanium dioxide is prepared by the following methods:

[0053] S1. Heating the silver nitrate solution in a water bath to 45°C, adding polyvinylpyrrolidone, adding tea polyphenols while stirring, and reacting for 1.5 hours to prepare nano-Ag particles;

[0054] S2. Take 1mol Ti(OC 4 h 9 ) 4 Mix with absolute ethanol, add 0.2mol nano-Ag particles, stir evenly to make liquid A; take 50mL absolute ethanol, 30mL glacial acetic acid and 20mL distilled water, mix evenly to make liquid B; slowly pour into liquid A while stirring Add liquid B dropwise, continue to stir until the solution becomes a gel, seal and age for 14 hours, put it in a drying oven for drying at a constant temperature of 80°C, take it out after it is completely dry, put it in a muffle furnace, and heat it at 6°C / h The heating rate was increased to 450°C, the calcination was continued for 2 hours, and the ball mill was taken out to obtain nanometer silver-loaded titanium dioxide.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com