A bismuth-based topological insulator material and preparation method thereof

A topological insulator, bismuth-based technology, applied in the field of bismuth-based topological insulator materials and its preparation, can solve the problems of expensive equipment, harsh process, complicated operation, etc., and achieve good topological insulation characteristics, strong industrial operation, and simple process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of bismuth-based topological insulator material of the present invention comprises the following steps:

[0036] Step 1: Take raw materials: silicon dioxide powder, sodium hydroxide powder, boron oxide powder, bismuth trioxide powder and selenium powder or tellurium powder; among them, silicon dioxide powder, sodium hydroxide powder, boron oxide powder, trioxide The molar ratio of bismuth powder and selenium powder is 4:4:1:(0.05-0.5):(0.05-0.5); or silicon dioxide powder, sodium hydroxide powder, boron oxide powder, bismuth trioxide powder and tellurium The molar ratio of the powder is 4:4:1:(0.05-0.5):(0.05-0.5).

[0037]Step 2: Grind the obtained silicon dioxide powder, sodium hydroxide powder, boron oxide powder, bismuth trioxide powder and selenium powder or tellurium powder in a mortar to mix the mixture evenly, and then add the evenly mixed mixture to the corundum Put the corundum crucible in a high-temperature electric furnace to melt the...

Embodiment 1

[0040] This example prepares Bi2Se 3 Topological insulator material, Bi2Se 3 The raw material components and dosage of the topological insulator material are as follows: the molar ratio of silicon dioxide powder, sodium hydroxide powder, boron oxide powder, bismuth trioxide powder and selenium powder is 4:4:1:0.1:0.1.

Embodiment B

[0041] In this embodiment Bi 2 Se 3 The preparation process of the topological insulator two-dimensional material is as follows:

[0042] Grind all the above raw materials for 10 minutes and mix them evenly, then add the mixture into a 100mL corundum crucible, then heat the corundum crucible to 900°C in a high-temperature electric furnace at 10°C / min, keep it warm for 10min, take out the corundum crucible and cool it to room temperature to obtain Bi 2 Se 3 volume. Bi in the cooled corundum crucible 2 Se 3 The block was separated from the corundum crucible, and ground for 30 minutes under the dispersion of an appropriate amount of isopropanol to form a powder, and then the ground powder was dispersed in 10 mL of isopropanol for 600 minutes under the ultrasonic dispersion instrument to obtain Bi 2 Se 3 Two-dimensional topological insulator materials.

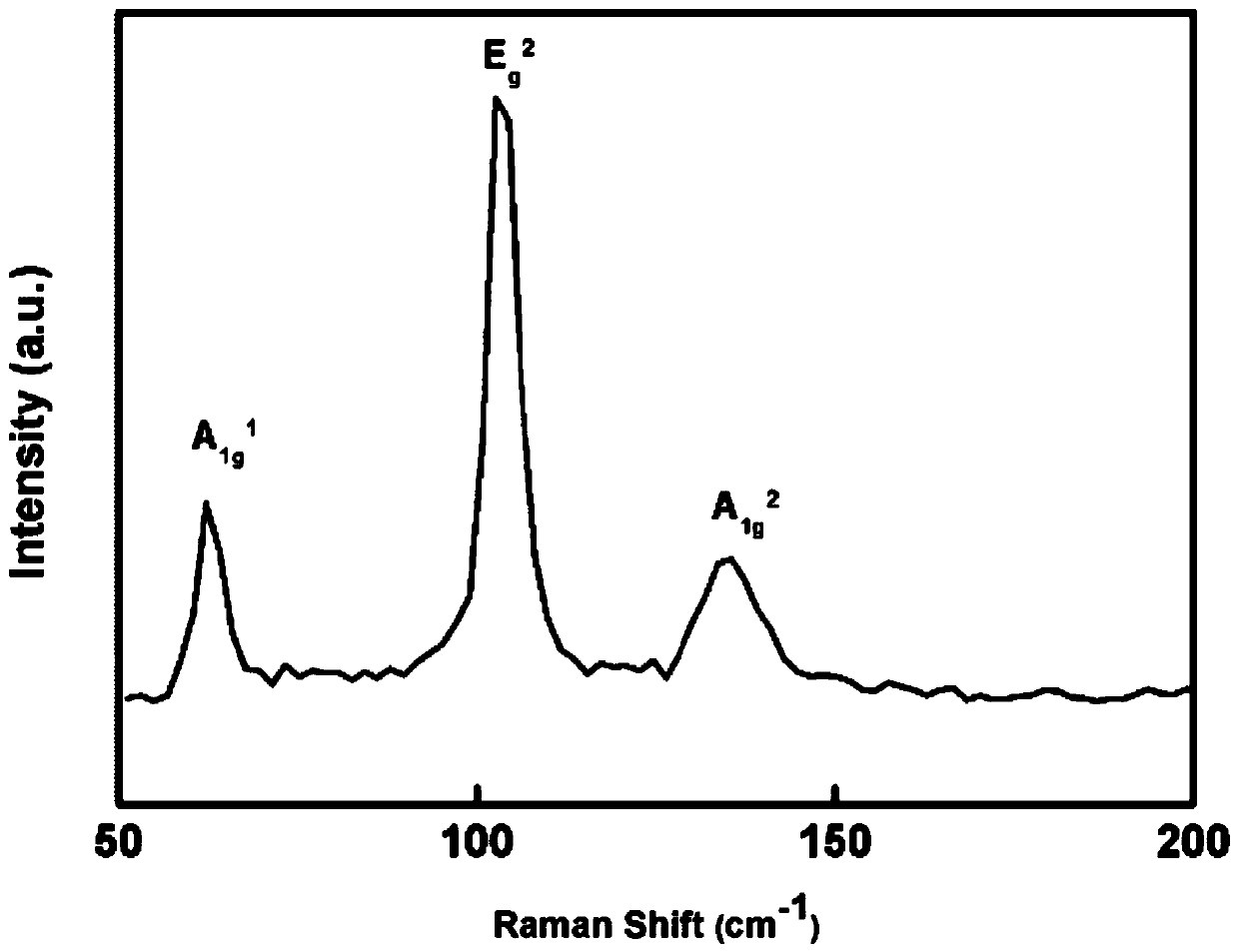

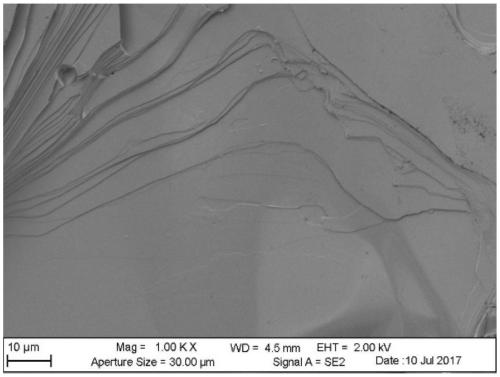

[0043] Such as figure 1 As shown, it can be clearly seen from the figure that Bi 2 Se 3 It is layered and is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com