Preparation technology of flame-resistant glass flake

A technology of glass flakes and preparation technology, which is applied in the direction of surface coating liquid devices, coatings, fireproof coatings, etc., can solve the problems of easy fire, equipment exposed to fire, etc., and achieve high anti-corrosion performance and increased distance between layers Large, heat-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

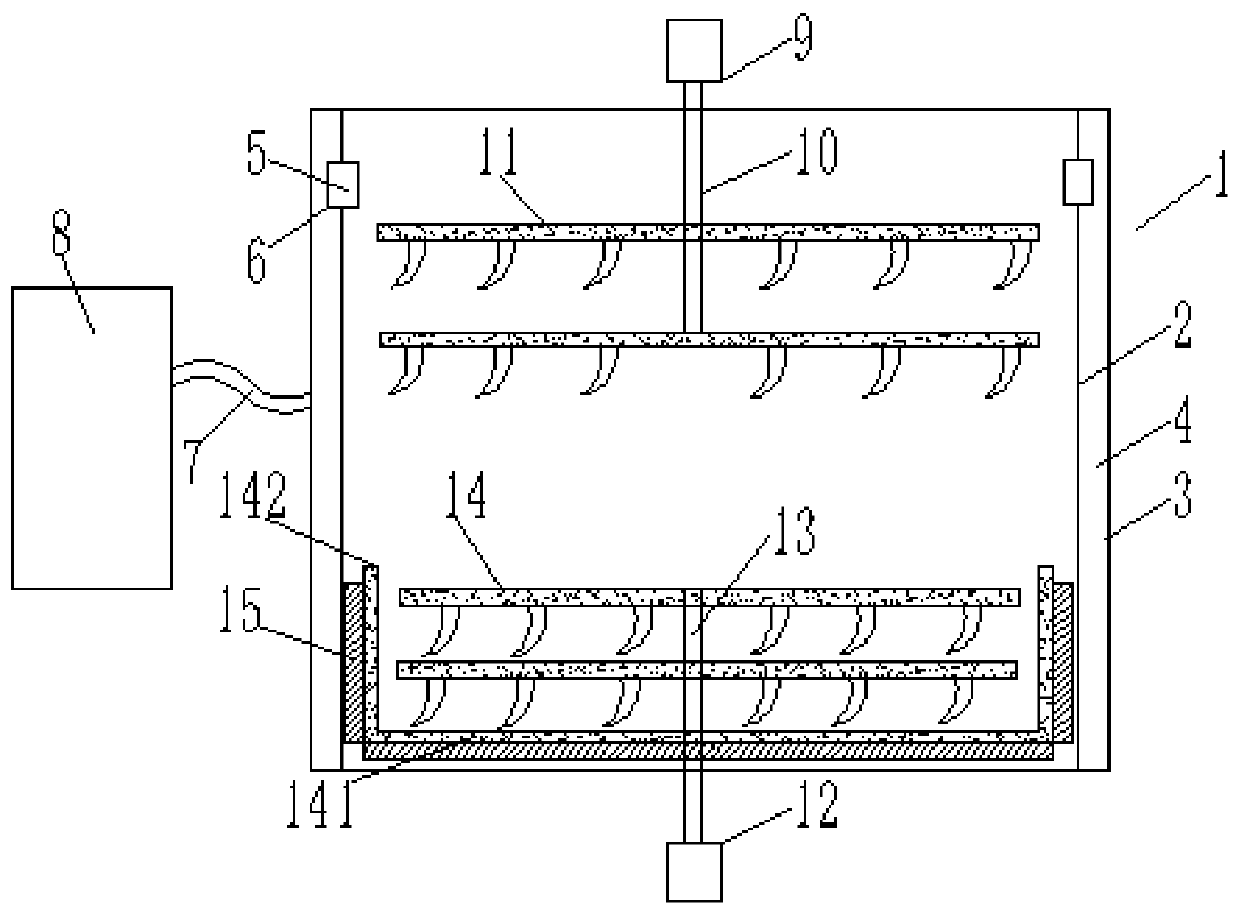

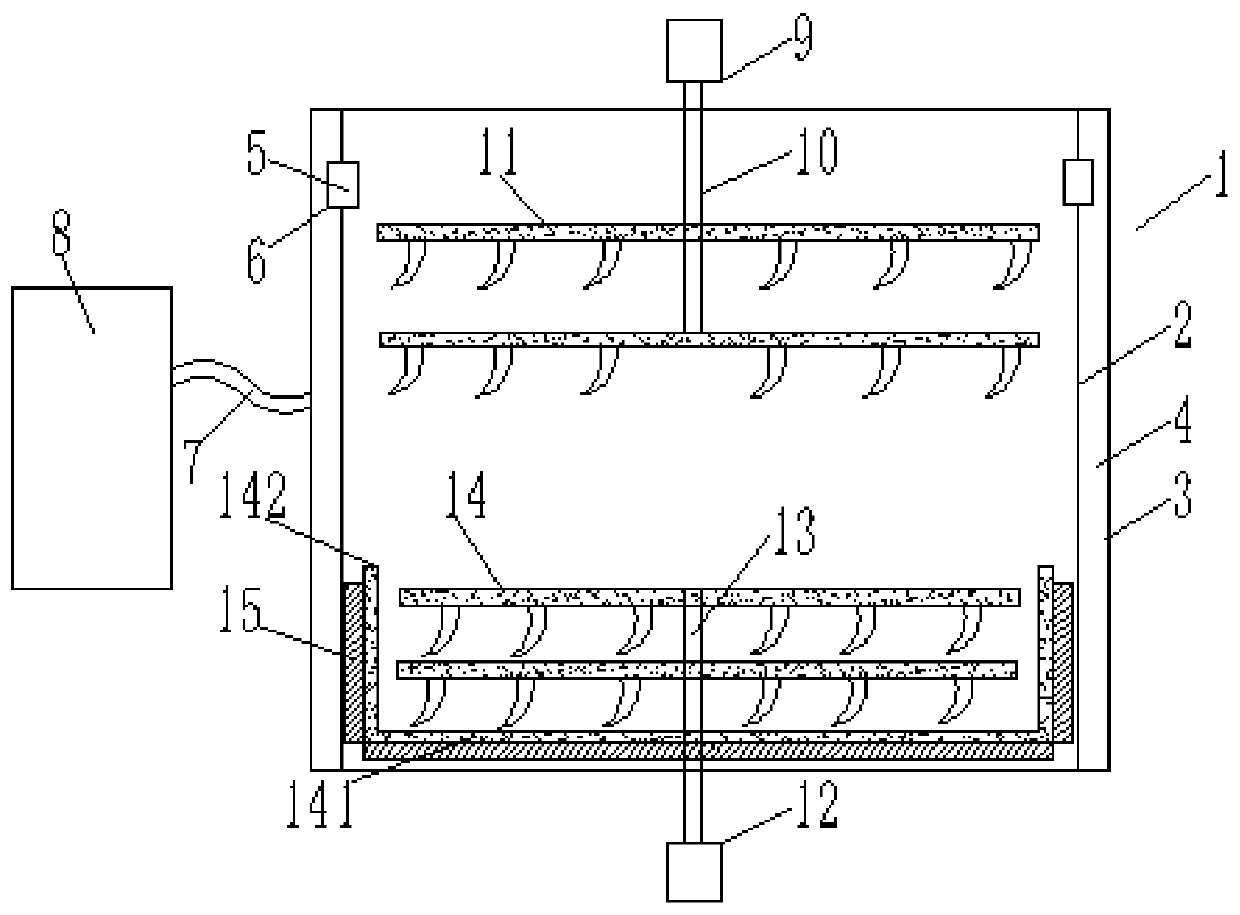

Image

Examples

Embodiment 1

[0030] A preparation process for flame-retardant glass flakes, comprising:

[0031] Step 1, spraying the primer layer on the surface of the base layer successively, and grinding the surface of the primer layer to form a rough surface; wherein, the primer layer is composed of vinyl ester resin with a mass ratio of 4:2:1:1:1, unsaturated Mixed composition of polyester resin, urea-formaldehyde resin, silicone resin and epoxy resin;

[0032] Step 2, spraying the structural layer on the surface of the primer layer, and grinding the surface of the structural layer to form a rough surface; wherein, the structural layer is composed of modified montmorillonite, modified bentonite, seawater with a mass ratio of 3:2:2:1 Composed of a mixture of porphyrite and epoxy resin; before use, the sepiolite needs to be soaked in 8% brine for 2 hours, then dried, pulverized, and set aside.

[0033] Step 3, spraying a topcoat on the surface of the structural layer to obtain the target product flame...

Embodiment 2

[0038] A preparation process for flame-retardant glass flakes, comprising:

[0039] Step 1, spraying the primer layer on the surface of the base layer successively, and grinding the surface of the primer layer to form a rough surface; wherein, the primer layer is composed of vinyl ester resin with a mass ratio of 4:2:1:1:1, unsaturated Mixed composition of polyester resin, urea-formaldehyde resin, silicone resin and epoxy resin;

[0040] Step 2, spraying the structural layer on the surface of the primer layer, and grinding the surface of the structural layer to form a rough surface; wherein, the structural layer is composed of modified montmorillonite, modified bentonite, seawater with a mass ratio of 3:2:2:1 Composed of a mixture of porphyrite and epoxy resin; before use, the sepiolite needs to be soaked in 8% brine for 2 hours, then dried, pulverized, and set aside.

[0041] Step 3, spraying a topcoat on the surface of the structural layer to obtain the target product flame...

Embodiment 3

[0046] A preparation process for flame-retardant glass flakes, comprising:

[0047] Step 1, spraying the primer layer on the surface of the base layer successively, and grinding the surface of the primer layer to form a rough surface; wherein, the primer layer is composed of vinyl ester resin with a mass ratio of 4:2:1:1:1, unsaturated Mixed composition of polyester resin, urea-formaldehyde resin, silicone resin and epoxy resin;

[0048] Step 2, spraying the structural layer on the surface of the primer layer, and grinding the surface of the structural layer to form a rough surface; wherein, the structural layer is composed of modified montmorillonite, modified bentonite, seawater with a mass ratio of 3:2:2:1 Composed of a mixture of porphyrite and epoxy resin; before use, the sepiolite needs to be soaked in 8% brine for 2 hours, then dried, pulverized, and set aside.

[0049] Step 3, spraying a topcoat on the surface of the structural layer to obtain the target product flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com