Suction type granule transferring AGV and method thereof

A technology of trolleys and granules, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., and can solve problems such as easy to drop and difficult to pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

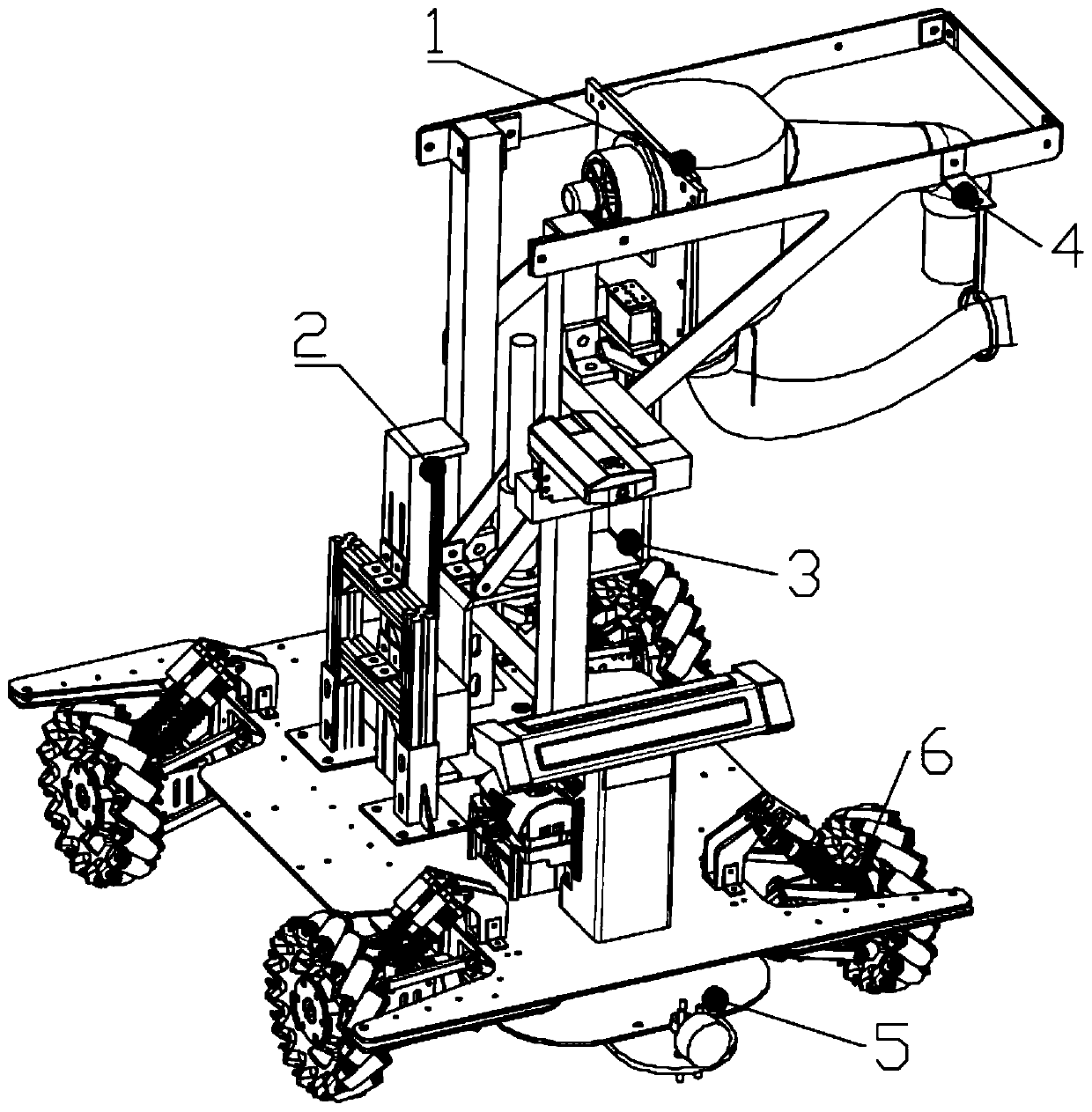

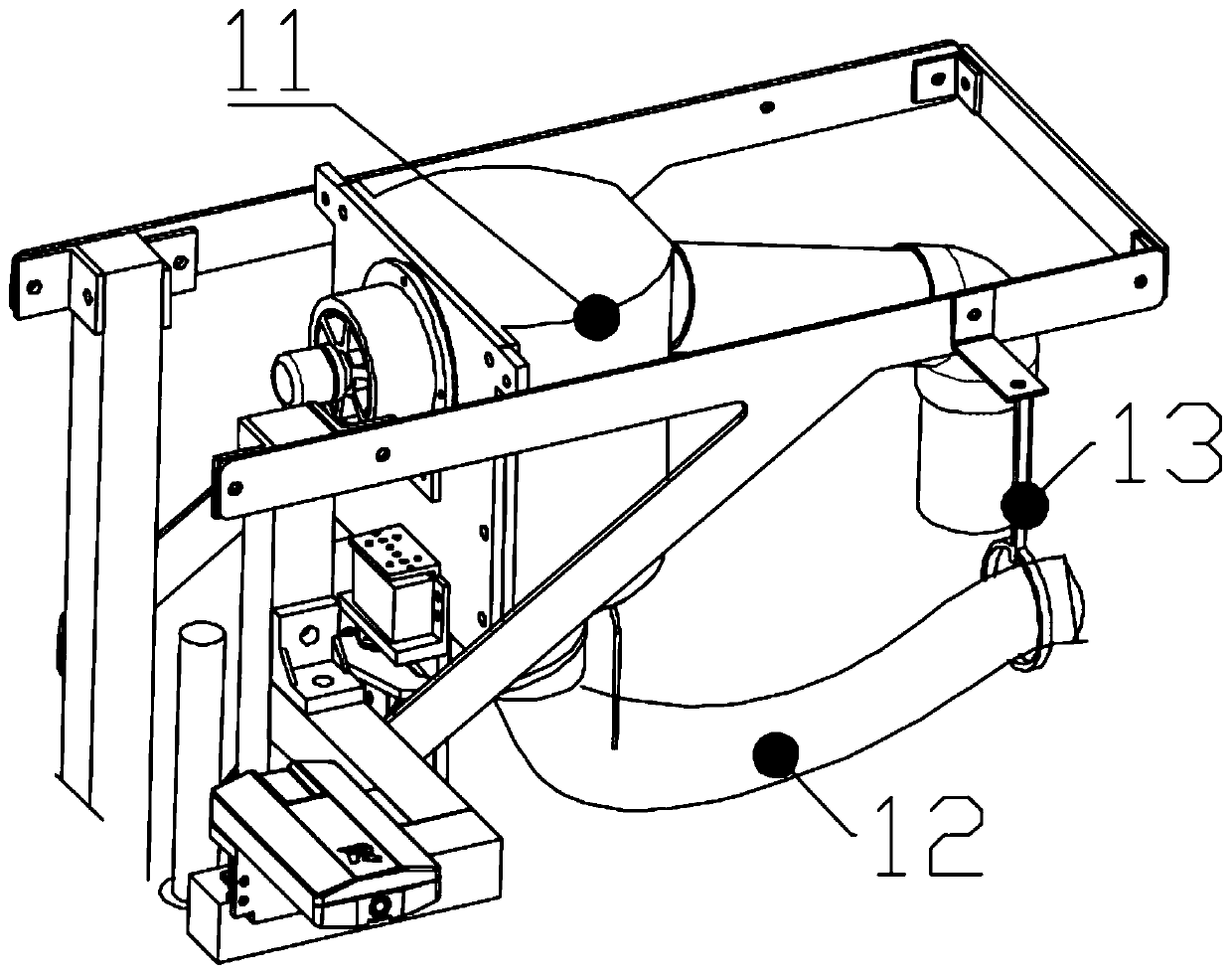

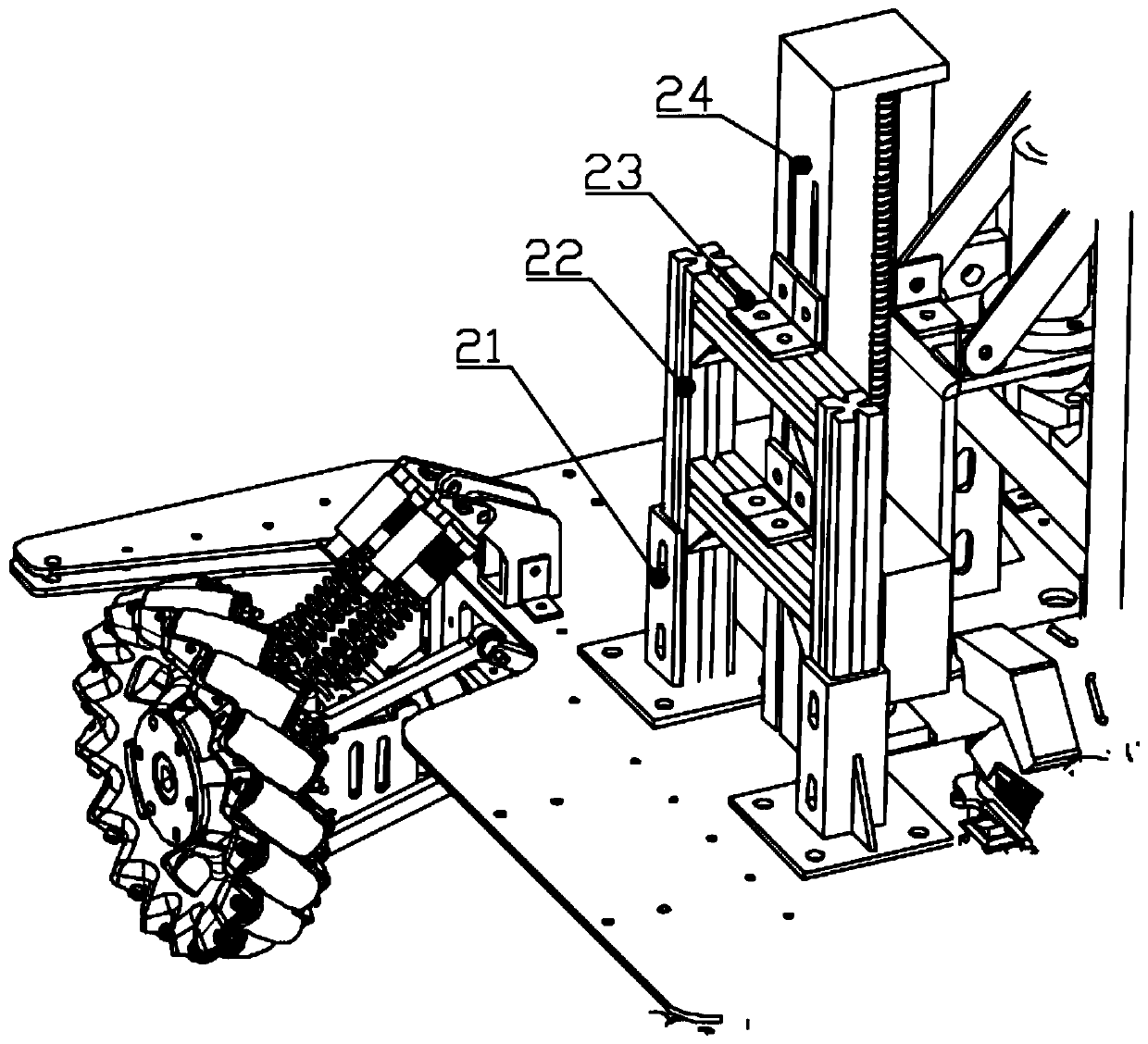

[0026] Such as figure 1 As shown, the suction-type particle handling AGV trolley includes a material pick-and-place mechanism 1, a lifting mechanism 2, a connecting mechanism 3, a protection mechanism 4, a cargo mechanism 5 and a running mechanism 6. The material pick-and-place mechanism 1 is connected and guided through the connection mechanism 3 and the lifting mechanism 2 through the connection mechanism 3, the protection mechanism 4 is fixedly connected with the connection mechanism 3, and the delivery mechanism 5 is connected to the front end of the vehicle body. When working, the material pick-and-place mechanism 1 realizes the acquisition and placement of materials, the lifting mechanism 2 realizes the lifting movement of the pick-and-place mechanism 1 in the vertical direction, and the connecting mechanism 3 provides connection and movement for the lift mechanism 2 and the material pick-and-place mechanism 1 When guiding, the protection mechanism 4 realizes the protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com