Grouting equipment used for manufacturing of cement prefabricated components

A cement prefabricated part and grouting technology, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of long grouting time, low work efficiency, and long intermittent time, and achieve simple piston movement structure and fast grouting intermittent time. Short, continuous effect of piston movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

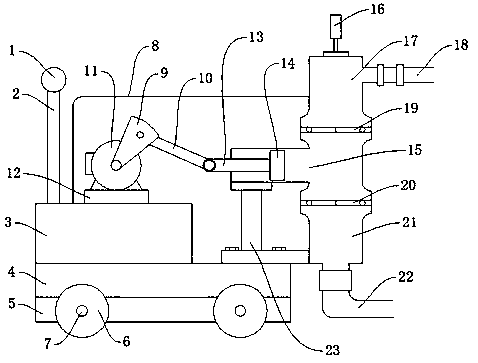

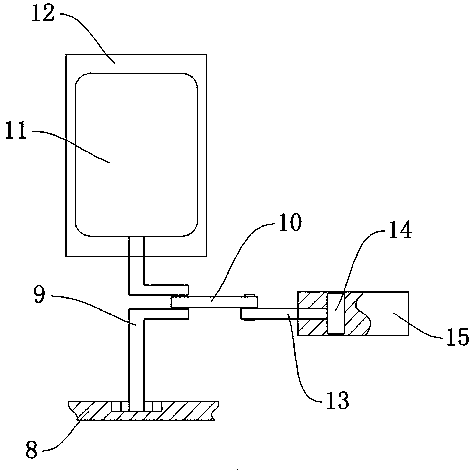

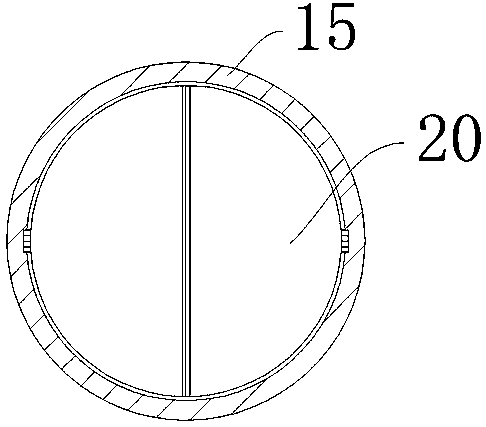

[0037] Such as Figure 1-Figure 3 As shown, a grouting equipment for processing cement prefabricated parts, including a wheel 6, a chassis 3, a motor 11, and a chassis 4, a rotating shaft 7 is arranged in the middle of the wheel 6, and the rotating shaft 7 is used to place the wheel 6 and allow the wheel 6 to rotate. A wheel frame 5 is arranged behind the wheel 6, and the wheel frame 5 is used to place the rotating shaft 7. A chassis 4 is arranged on the wheel frame 5, and the chassis 4 is used for stabilizing the supporting equipment. A chassis 3 is arranged on the chassis 4, and a base is arranged on the chassis 3. 12. The base 12 is used to place the motor 11. The motor 11 is arranged on the base 12. The motor 11 is used to provide power. The side of the motor 11 is provided with a bracket 2. The bracket 2 is used to place the armrest 1. The armrest 1 is arranged on the bracket 2. Handrail 1 is used for pushing, and crankshaft 9 is arranged in front of motor 11, and cranksh...

Embodiment 2

[0039]A grouting equipment for processing cement prefabricated parts, including a wheel 6, a chassis 3, a motor 11, and a chassis 4. A rotating shaft 7 is arranged in the middle of the wheel 6. The rotating shaft 7 is used to place the wheel 6 and allow the wheel 6 to rotate. A wheel frame 5 is provided, and the wheel frame 5 is used to place the rotating shaft 7. The wheel frame 5 is provided with a chassis 4, and the chassis 4 is used for stabilizing the supporting equipment. The chassis 4 is provided with a chassis 3, and the chassis 3 is provided with a base 12. 12 is used to place the motor 11, the base 12 is provided with the motor 11, the motor 11 is used to provide power, the side of the motor 11 is provided with a bracket 2, the bracket 2 is used to place the armrest 1, and the armrest 1 is arranged on the bracket 2, and the armrest 1 is used For pushing, the front of the motor 11 is provided with a crankshaft 9, the crankshaft 9 is used to drive the rocker 10 to rotat...

Embodiment 3

[0041] A grouting equipment for processing cement prefabricated parts, including a wheel 6, a chassis 3, a motor 11, and a chassis 4. A rotating shaft 7 is arranged in the middle of the wheel 6. The rotating shaft 7 is used to place the wheel 6 and allow the wheel 6 to rotate. A wheel frame 5 is provided, and the wheel frame 5 is used to place the rotating shaft 7. The wheel frame 5 is provided with a chassis 4, and the chassis 4 is used for stabilizing the supporting equipment. The chassis 4 is provided with a chassis 3, and the chassis 3 is provided with a base 12. 12 is used to place the motor 11, the base 12 is provided with the motor 11, the motor 11 is used to provide power, the side of the motor 11 is provided with a bracket 2, the bracket 2 is used to place the armrest 1, and the armrest 1 is arranged on the bracket 2, and the armrest 1 is used For pushing, the front of the motor 11 is provided with a crankshaft 9, the crankshaft 9 is used to drive the rocker 10 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com