Fault detection method and system for an electric air compressor

An electric air compressor and fault detection technology, which is applied in the direction of machines/engines, pump testing, mechanical equipment, etc., can solve the problem of incomplete air compressor failure detection, achieve a high degree of functional safety guarantee, short detection intervals, and detection wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

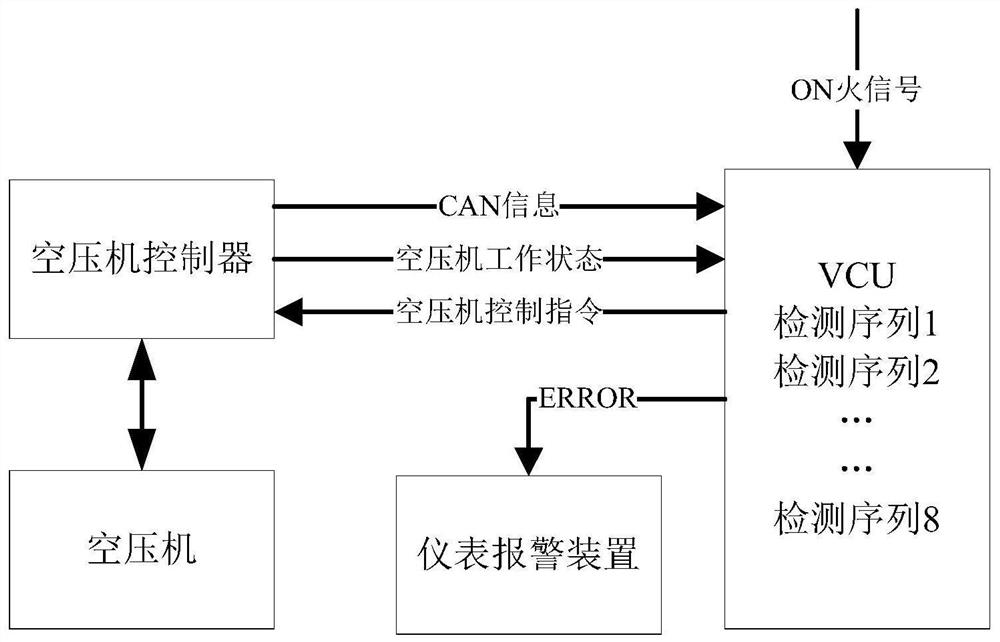

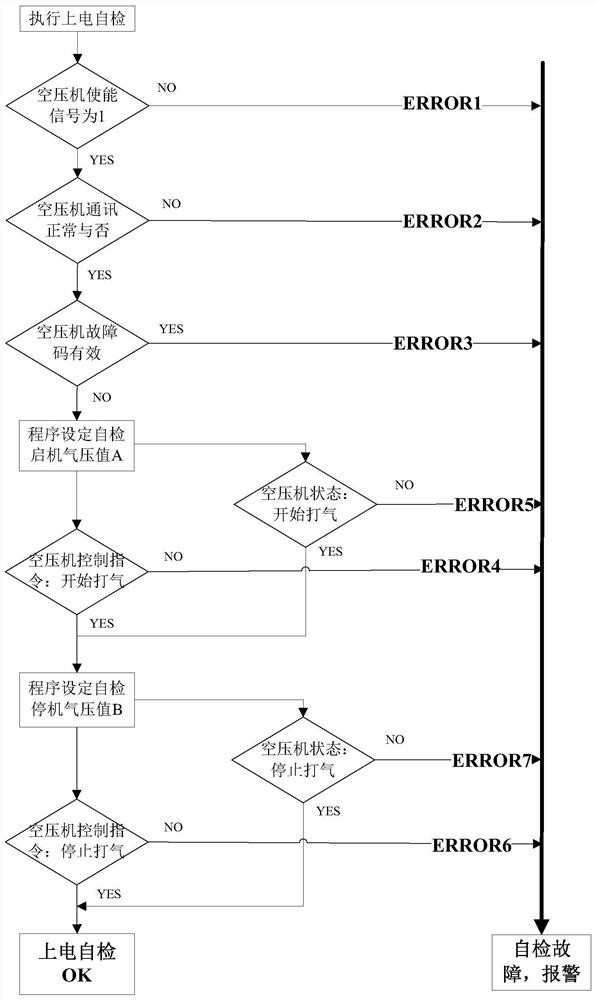

[0027] Such as figure 1 As shown, the fault detection system of the electric air compressor of the present invention includes a vehicle controller VCU, an air compressor controller and an instrument alarm device, wherein the vehicle controller VCU communicates with the air compressor controller through hard wiring, and The control is connected to the instrument alarm device; the air compressor controller is connected to the air compressor.

[0028] The above-mentioned air compressor controller is used to detect the working state of the air compressor, and send the fault information of the air compressor itself to the vehicle controller VCU, so that the VCU can make a fault judgment decision.

[0029] The above-mentioned vehicle controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com