Self-melting colored permeable integral pavement

A technology of self-melting snow and colored surfaces, which is applied to roads, roads, on-site paved condensate pavements, etc., can solve the problems of insufficient load-bearing of ordinary permeable pavements and cannot meet the freeze-thaw resistance in the north, and achieve improved snow removal efficiency and enhanced Aesthetics, the effect of alleviating rainstorm and flood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

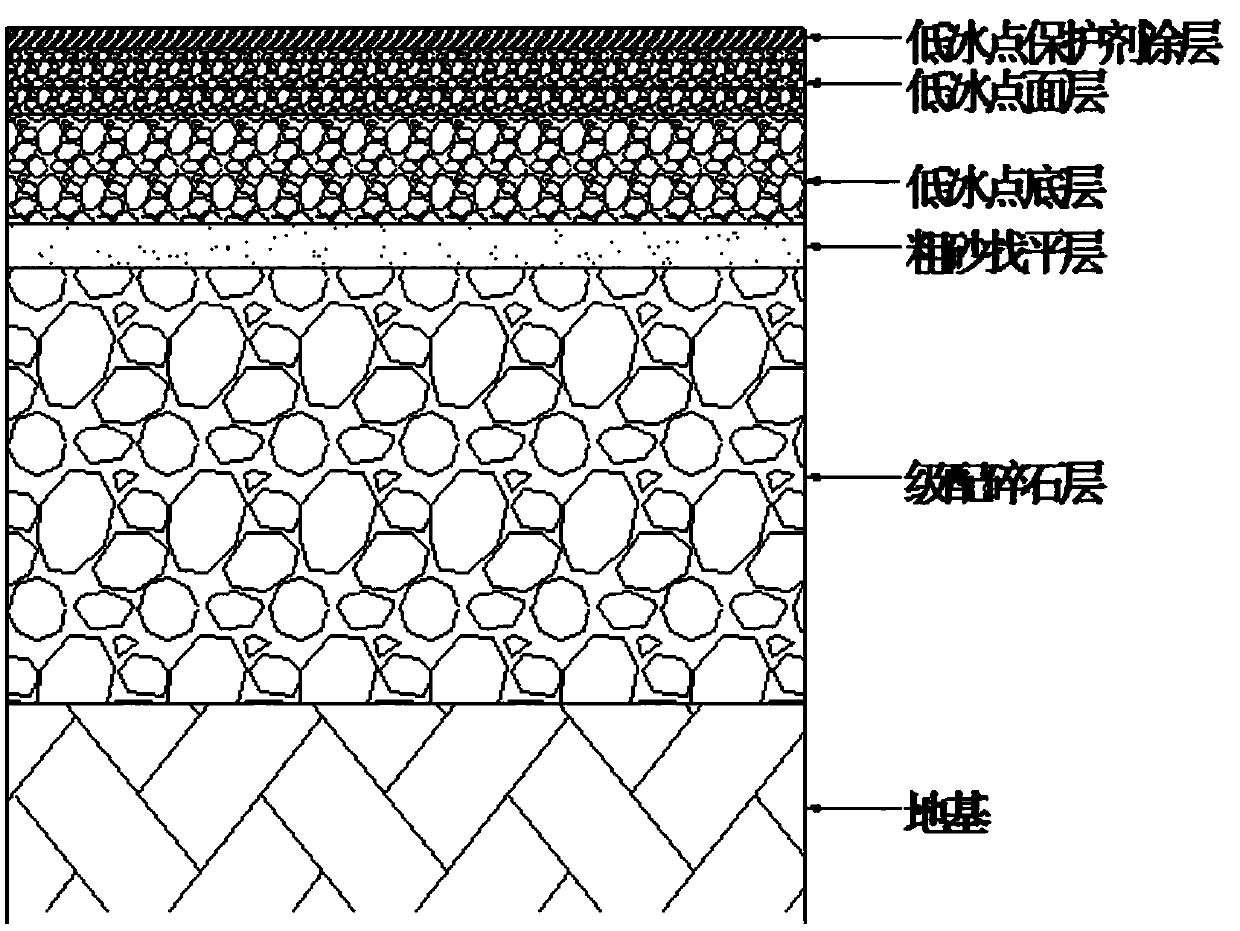

[0017] Such as figure 1 As shown, the present invention provides a self-melting snow-melting colored water-permeable monolithic pavement, said pavement comprising a low freezing point protective agent coating, a low freezing point colored surface layer, a low freezing point primary color bottom layer, a coarse sand leveling layer, Graded crushed stone layer and plain soil layer, figure 1 The foundation given above is the plain soil layer.

[0018] Wherein, the thickness of low freezing point protective agent coating is 0.1~0.3mm, in a specific embodiment, thickness is 0.2mm, and low freezing point protective agent coating is to add low freezing point material in protective agent, and the composition of protective agent is Acrylic resin 63-73%, film-forming agent 3-5%, coagulant aid 2-3%, polyurethane 14-17%, propylene glycol 1-2%, pigment 8-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com