Automatic suction and separation device and method of flexible strip-shaped food

A separation equipment and strip technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of high labor intensity, low work efficiency, labor cost of food secondary pollution, etc., to solve the problem of high labor cost , solve the secondary pollution, improve the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

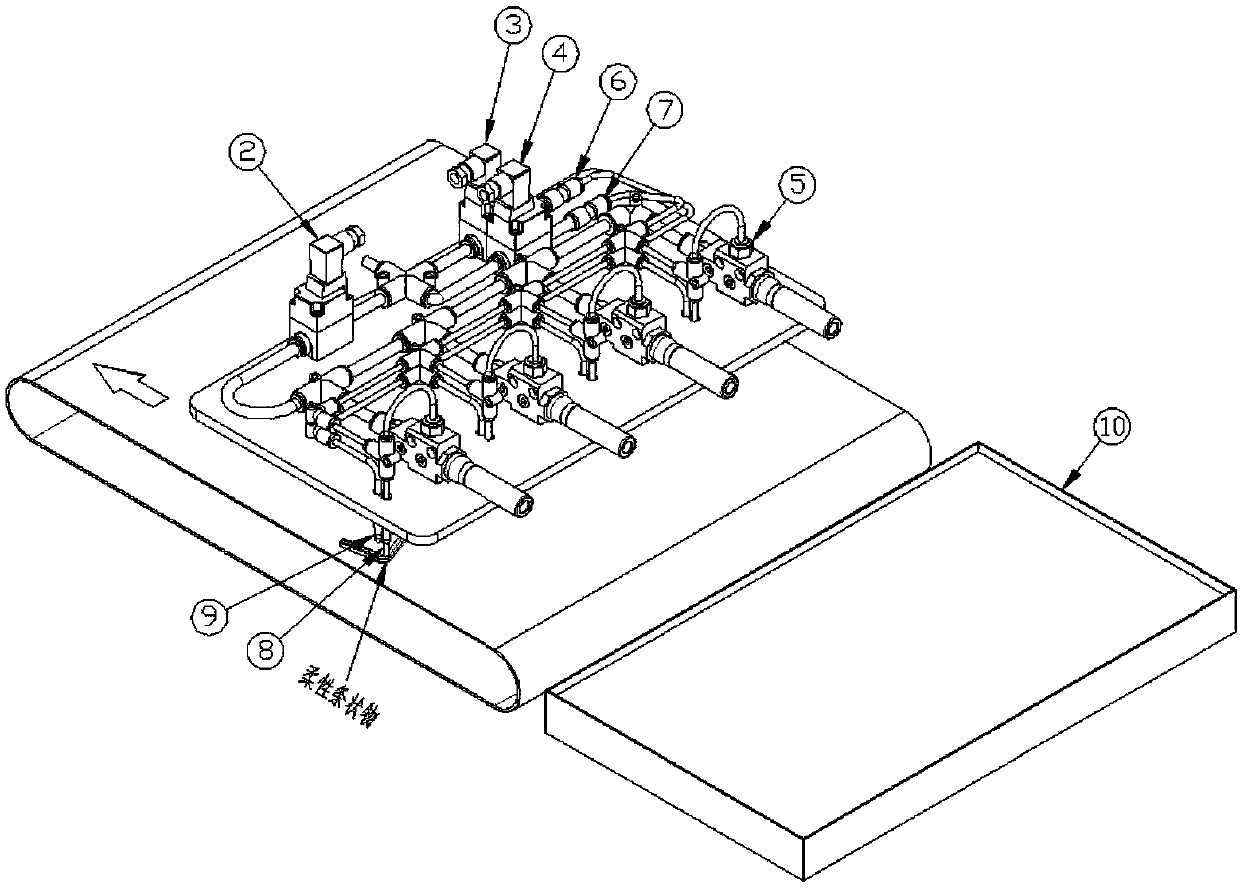

[0031] This embodiment provides an automatic suction and separation device for flexible strip food, see Figure 1 to Figure 3 , the flexible strip-shaped food automatic absorption and separation equipment includes: a separation device, a transmission device, and a power device, and the separation device and the transmission device are respectively connected to the power device.

[0032] The flexible strip-shaped food automatic suction and separation equipment also includes a raw material supply bin ⑩, which is used to hold the flexible strip-shaped food to be separated.

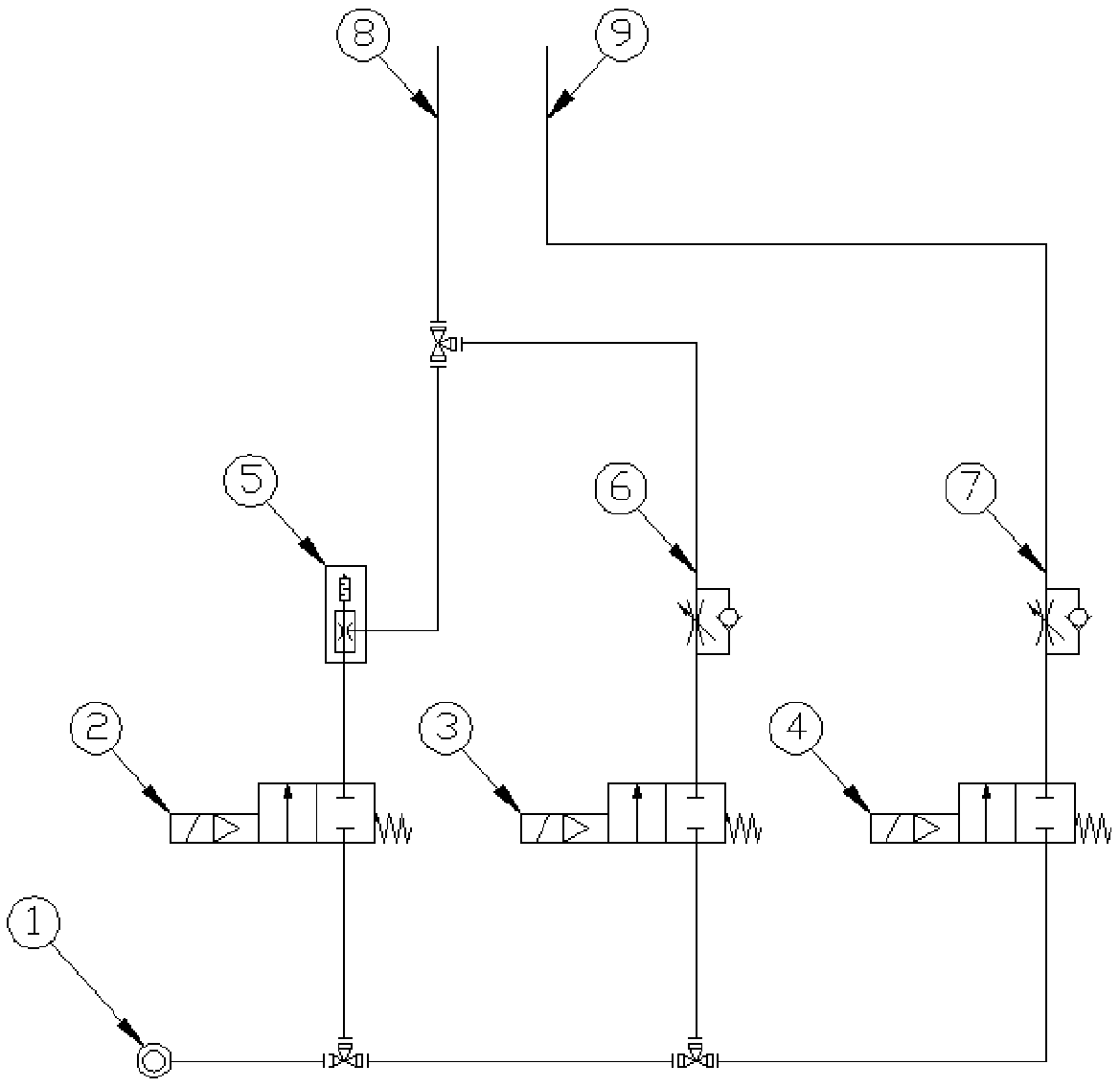

[0033] The separation device includes: power source compressed air ①, separation suction part and separation blowing part, wherein the power source compressed air ① is connected to the power device, and the separation suction part and separation blowing part are respectively connected to the power source compressed air ①.

[0034] The power unit is the equipment that provides power for the whole equipment, an...

Embodiment 2

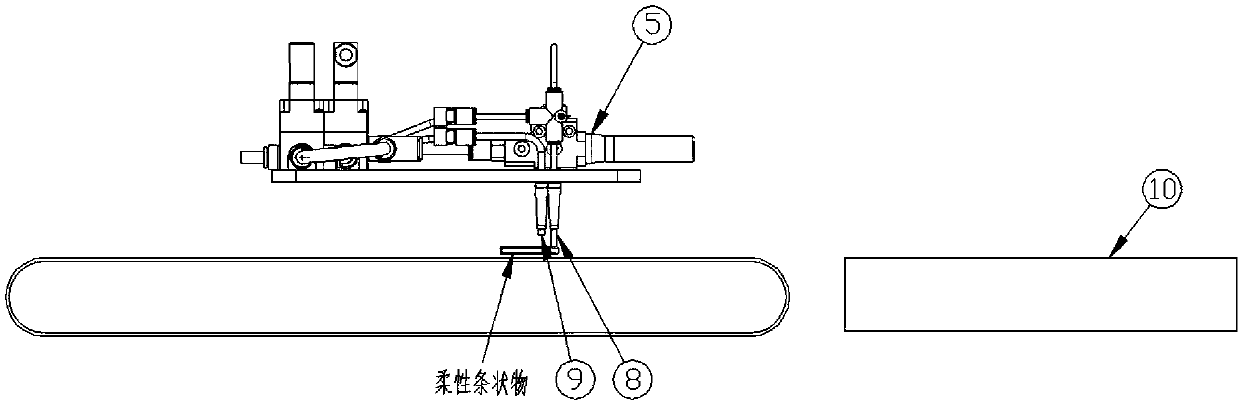

[0046] This embodiment provides a method for automatic suction and separation of flexible strip food, see Figure 4 , the method for automatic absorption and separation of flexible strip-shaped food is applied to the automatic absorption and separation equipment for flexible strip-shaped food provided in Embodiment 1, including:

[0047] Turn on the automatic suction and separation equipment for flexible strip-shaped food, use the separation device to separate the flexible strip-shaped food and place it on the conveying device, and the conveying device will convey it to the next processing process, where the separating device and the conveying device are provided by the power device power.

[0048] Specifically, the separation device descends to the raw material supply bin ⑩ to suck flexible food strips from it. When the vacuum solenoid valve ② is opened and the separation solenoid valve ③ is closed, the gas will pass through the vacuum generator ⑤. Negative pressure can be g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com