Slide block type device for powder spraying and wax injection

A slider-type, powder-spraying technology, which is applied in the direction of casting and molding equipment, can solve problems such as low efficiency, uneven powder spraying, time-consuming and labor-intensive problems, and achieve the effect of improving work efficiency and improving the pass rate

Active Publication Date: 2019-04-30

盐城恒远投资发展有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Before injecting the wax liquid, it is often necessary to spray powder into the cavity of the mold, and the powder spraying is often done by manually opening the mold first, and then spraying the powder, which is time-consuming, laborious, inefficient, and the amount of powder spraying cannot be controlled. It leads to uneven powder spraying in each mold, which affects the qualified rate of wax mold molding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

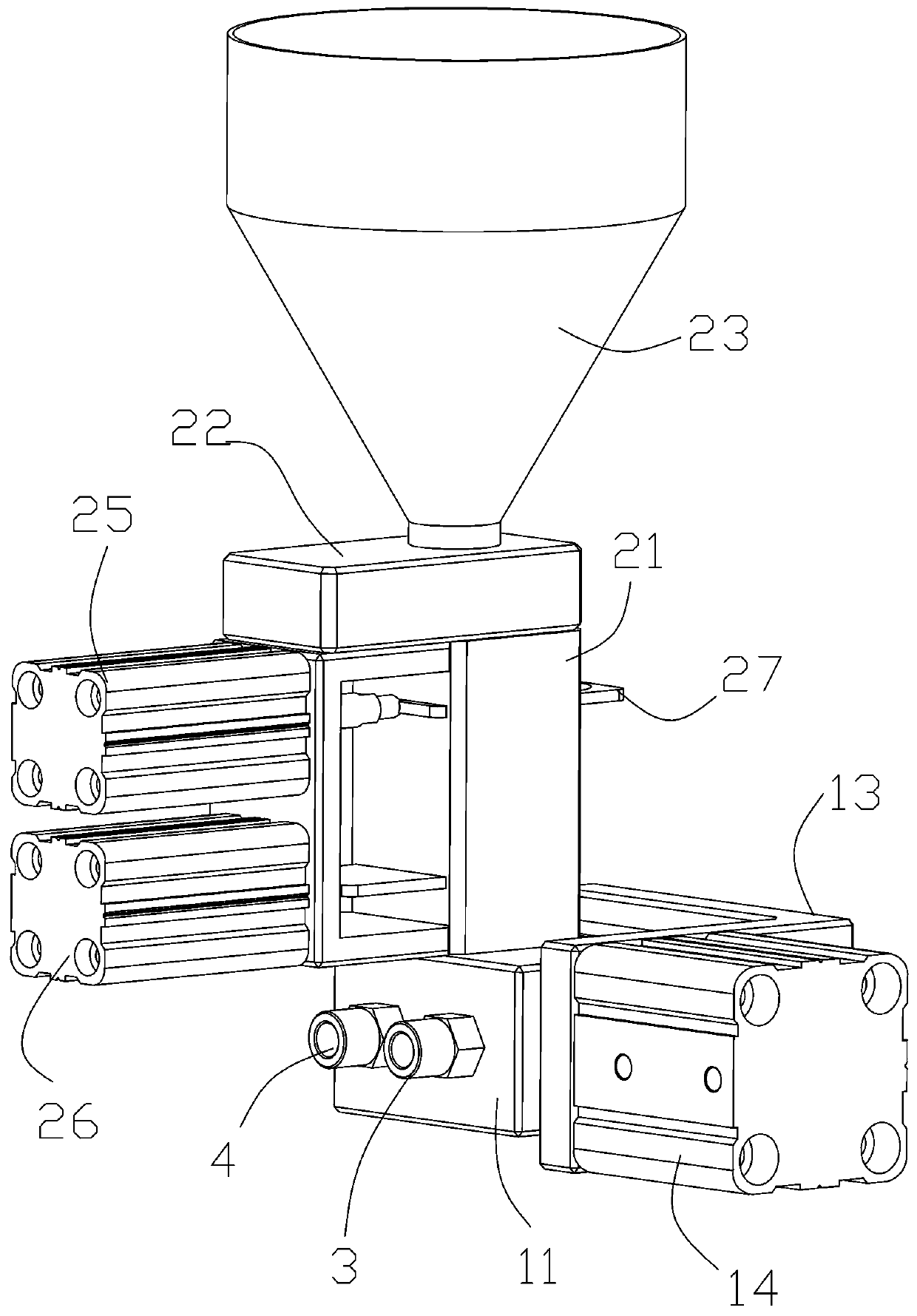

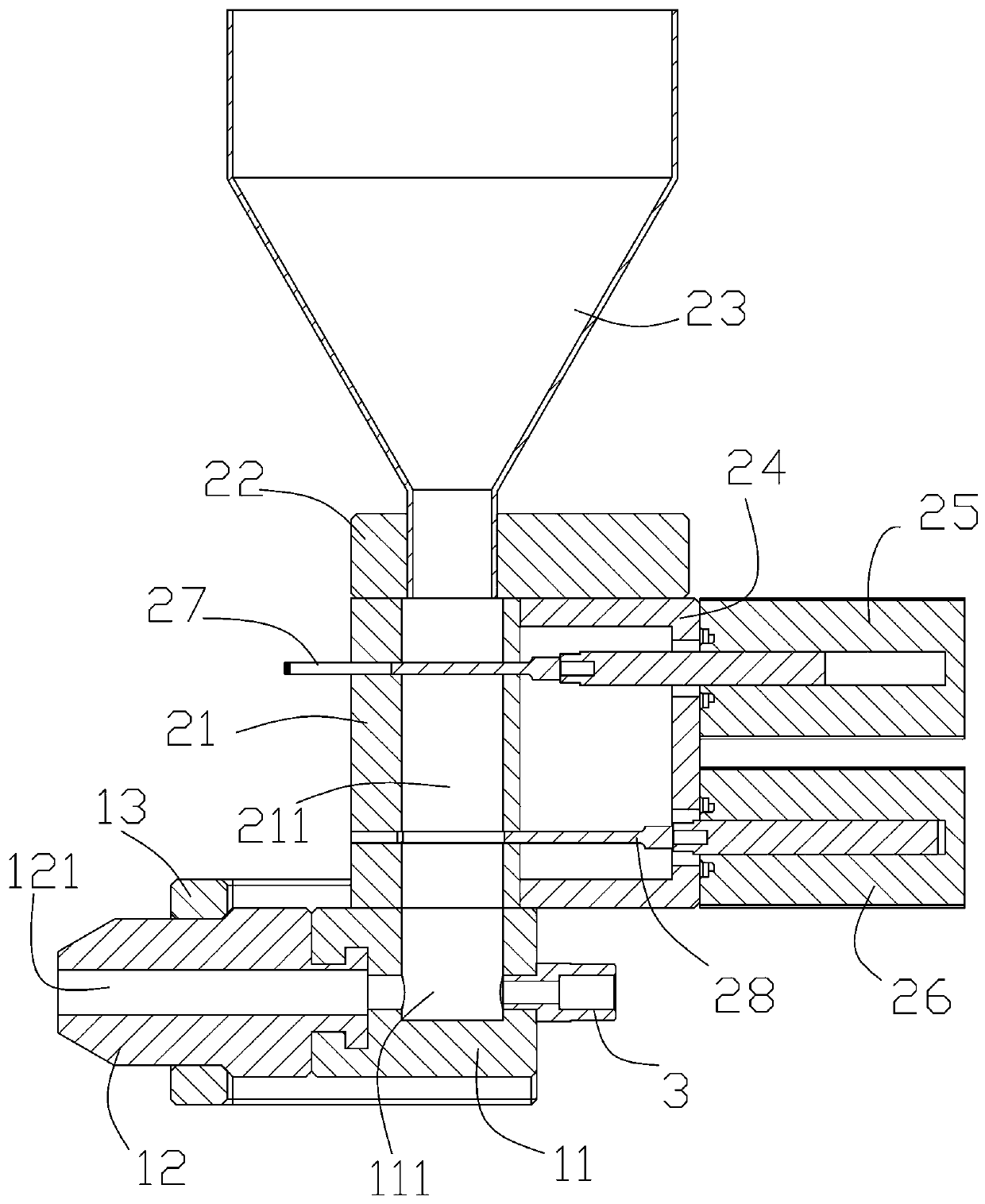

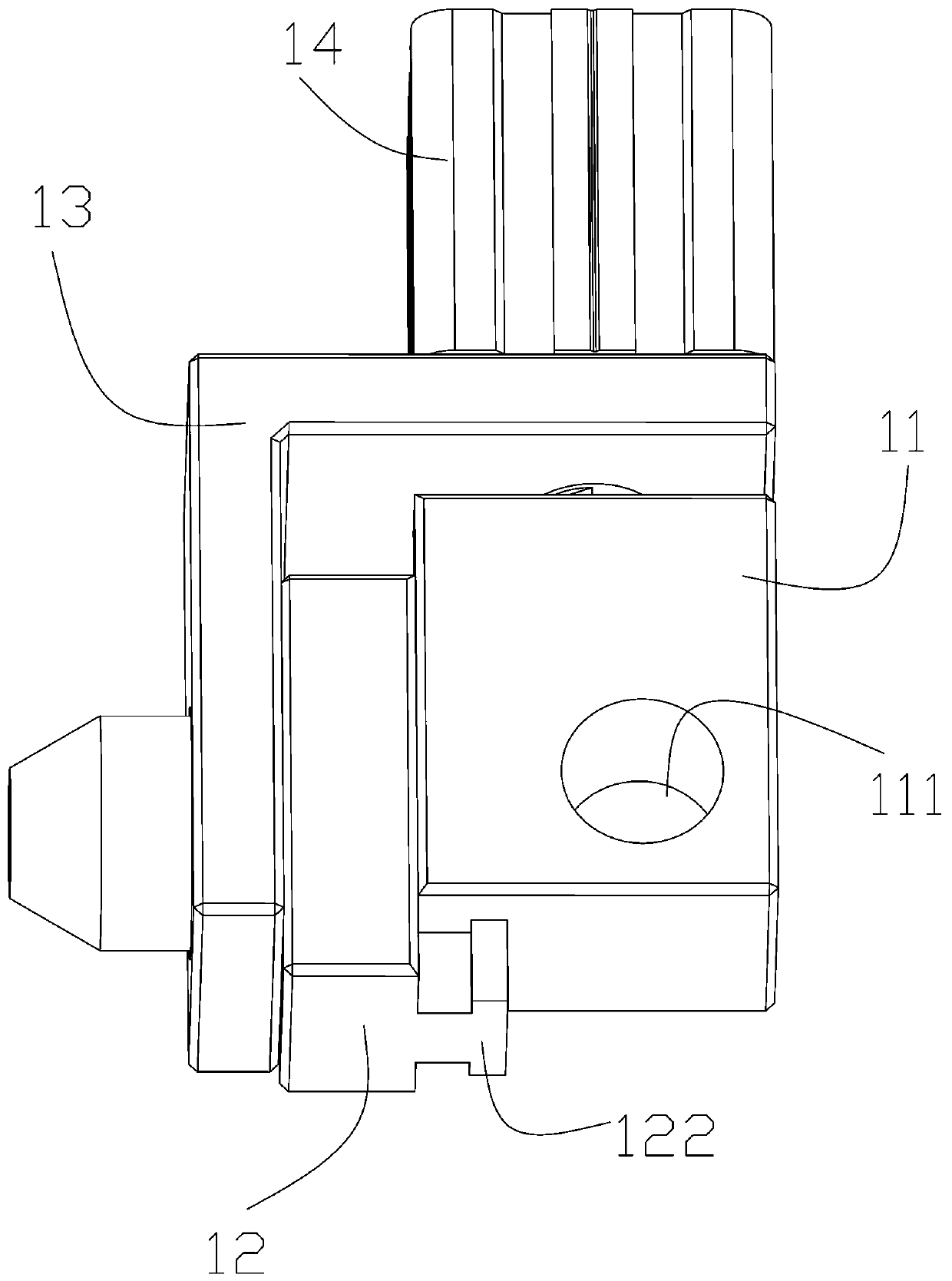

The invention discloses a slide block type device for powder spraying and wax injection. The slide block type device for powder spraying and wax injection comprises a quantitative powder feeding part,a material injection part, a wax liquid injection nozzle and a vacuum interface, wherein the quantitative powder feeding part is used for quantitatively conveying powder for the material injection part, the material injection part comprises a feeding nozzle, a first air cylinder and a feeding sliding block, and the feeding nozzle is in sliding connection with the feeding sliding block; the wax liquid injection nozzle and the vacuum interface are connected with the feed sliding block; a first through hole and a second through hole are formed in the feeding sliding block; a material injection through hole is formed in the feeding nozzle; and under the drive of the first air cylinder, the first through hole communicates with the material injection through hole or the second through hole communicates with the material injection through hole. According to the slide block type device for powder spraying and wax injection, the first air cylinder drives the feeding sliding block to move to switch powder spraying and wax injection, so that the powder spraying and wax injection are integrally completed, and the working efficiency is greatly improved; and meanwhile, two baffle plates are arranged to realize quantitative conveying of powder under the drive of the air cylinders, so that powder spraying in a mould is uniform every time, the uneven manual powder spraying is prevented from influencing the forming of a wax mould, and the qualified rate of the wax mould forming is improved.

Description

technical field The invention relates to the technical field of wax injection equipment, in particular to a slider-type device for powder spraying and wax injection. Background technique In the prior art, the wax injection machine is an important basic equipment in the jewelry and handicraft industries. It is used to make wax models. First, the inside of the mold is evacuated, and then wax is injected into the mold. After the wax solidifies, the wax model is taken out. Before injecting the wax liquid, it is often necessary to spray powder into the cavity of the mold, and the powder spraying is often done by manually opening the mold first, and then spraying the powder, which is time-consuming, laborious, inefficient, and the amount of powder spraying cannot be controlled. As a result, the powder spraying in each mold is uneven, which affects the qualified rate of wax mold molding. Contents of the invention The purpose of the present invention is to overcome the above-men...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C39/02B29C39/22B29C39/24B29C33/58

CPCB22C7/02

Inventor 聂琮力

Owner 盐城恒远投资发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com