Self-propelled tunnel lining dismantling equipment and using method

A self-propelled, lining technology, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of strong lining disturbance, endangering personal safety, low reliability, etc., to reduce disturbance or damage, ensure personnel safety, and avoid structural failure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

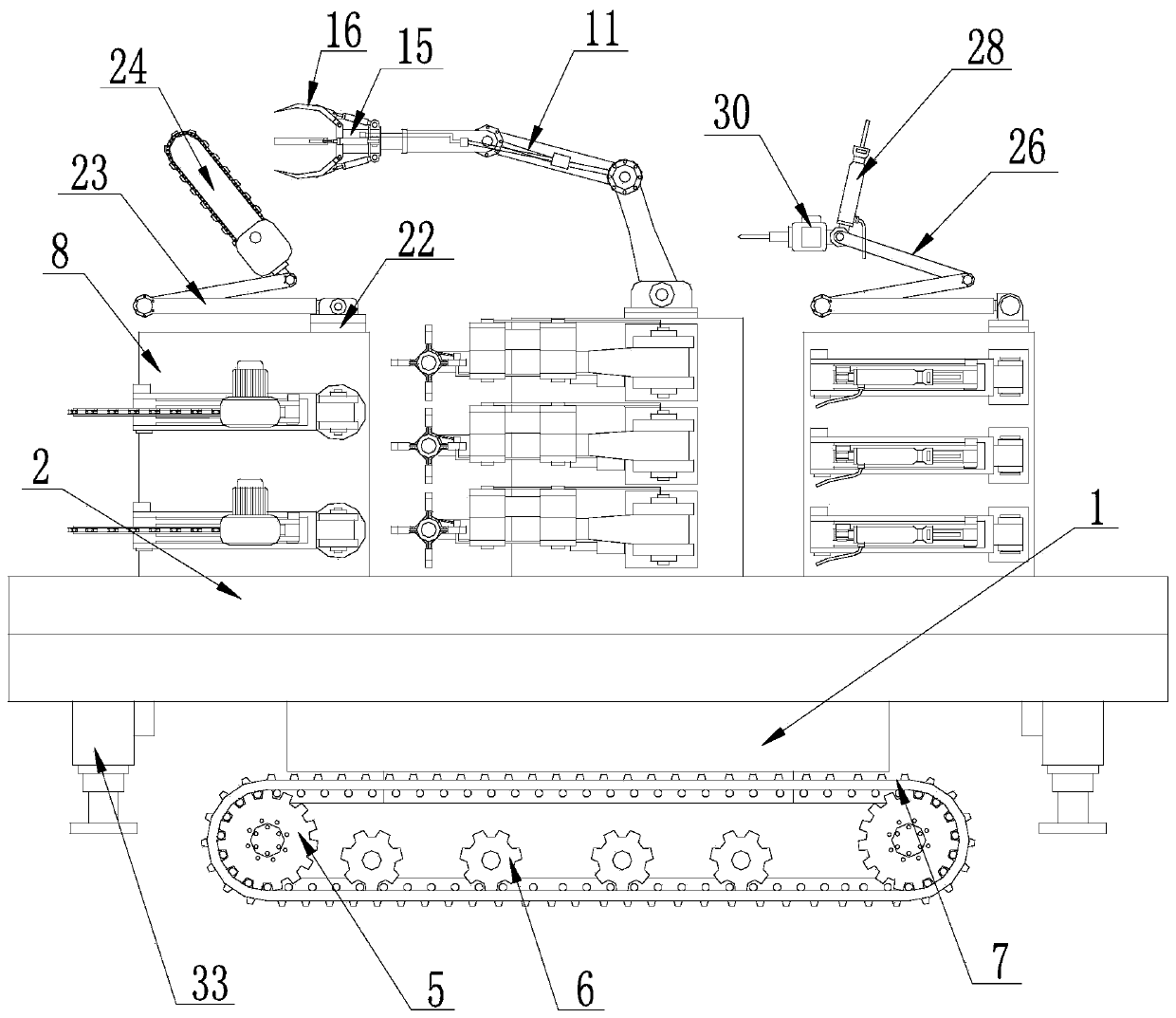

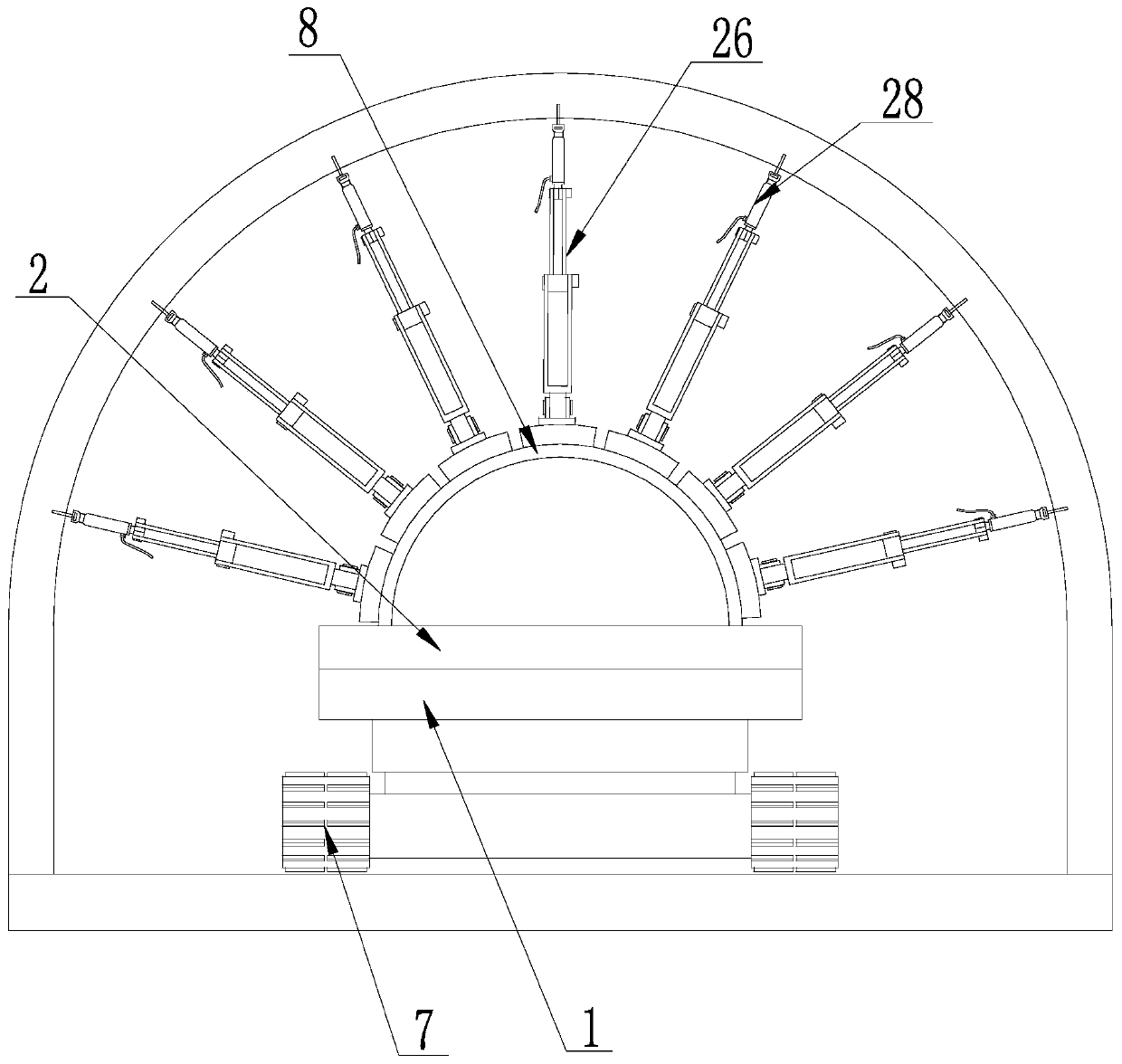

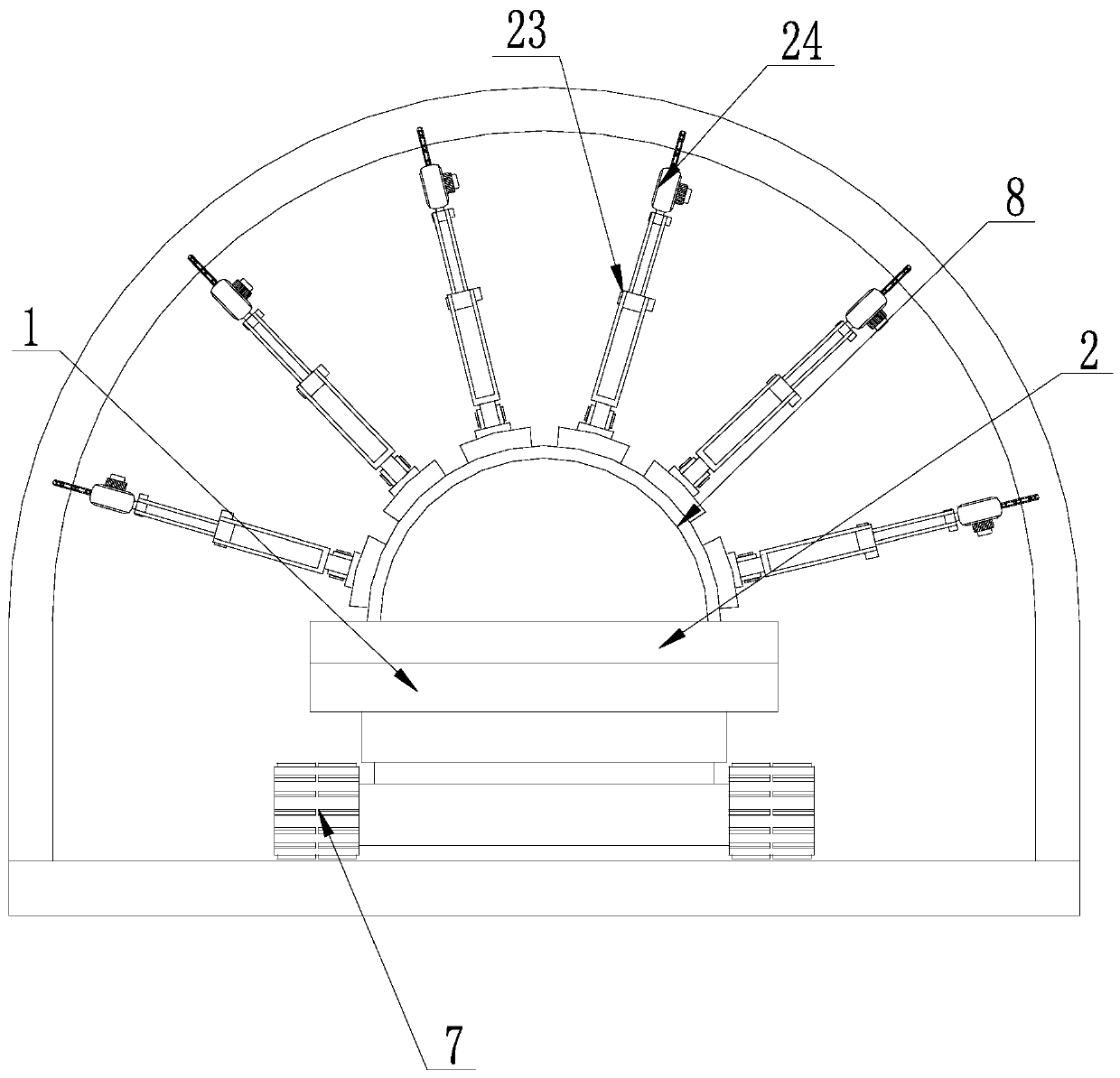

[0077] Such as figure 1 As shown, a self-propelled tunnel lining removal equipment includes a vehicle frame 1, a slewing platform 2 installed on the upper end of the vehicle frame 1, and a walking device installed on the lower side of the vehicle frame 1. The walking device is crawler-type in the figure The running gear, the running gear includes but is not limited to a crawler type running gear, tire type (for example, road tunnels with road surface protection requirements), wheel-rail type (for example, non-stop railway Tunnels, subway tunnels), whether it is a crawler-type running mechanism, a tire-type running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com