Automated assembly system for prefabricated buildings

An assembly system and assembly technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of increased installation costs, misuse of bolts, and difficult to distinguish shapes, and achieve the effect of relatively small size, large capacity, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] An automated assembly system for prefabricated buildings, building components with mounting holes and bolts of different grades, each mounting hole has a corresponding matching bolt.

[0033] A two-dimensional code is printed on the top surface of the bolt head, and the specification and grade information of the bolt can be obtained by identifying the two-dimensional code of the bolt. There is a QR code printed next to the mounting hole. By identifying the QR code of the mounting hole, the specification and grade information of the bolts used in the mounting hole can be obtained. The two-dimensional codes of the bolts and the mounting holes are covered with a plastic protective film to prevent the two-dimensional codes from being worn.

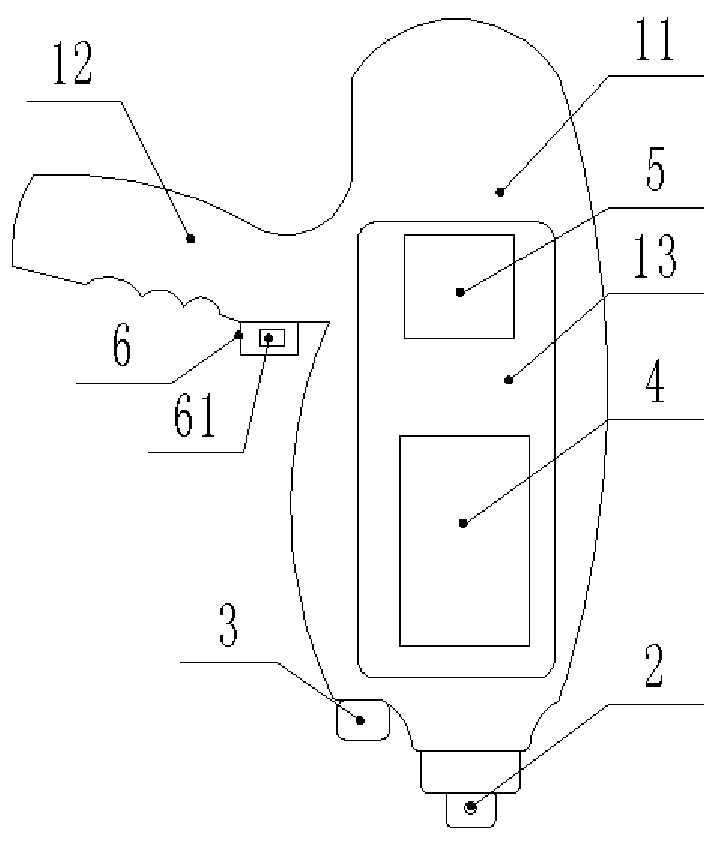

[0034] The automated assembly system for prefabricated buildings also includes smart wrenches, such as figure 1 As shown: a smart wrench, including a wrench body 11 and a handle 12 fixedly connected to the wrench body 11 . The front e...

Embodiment 2

[0047] Compared with Embodiment 1, this embodiment differs only in that this embodiment also includes a bolt finishing device.

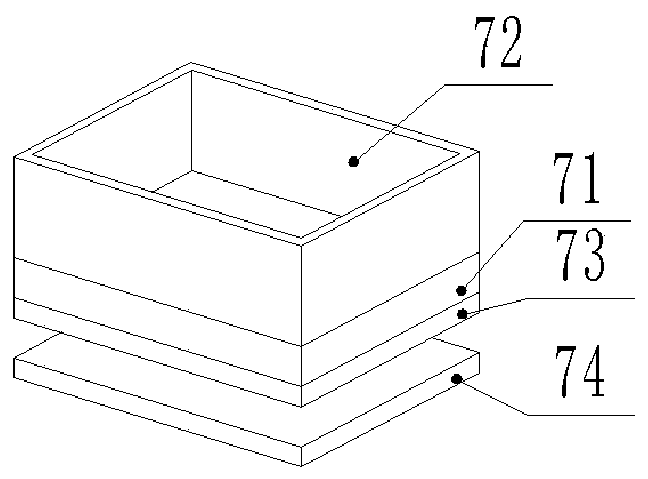

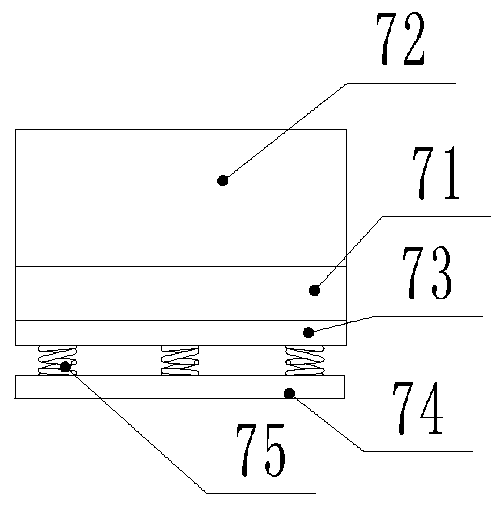

[0048] Such as figure 2 and image 3 Shown: bolt finishing device, comprises base plate 71, enclosure plate 72, magnet 73 and base 74, base plate 71 upper end is fixedly connected with enclosure plate 72, base plate 71 lower end is fixedly connected with magnet 73, is fixed between magnet 73 and base 74 Elastic element 75. In this embodiment, the elastic element 75 is a spring.

[0049] Such as Figure 4 As shown: the base plate 71 is uniformly provided with placement holes 701 perpendicular to the base plate 71, and the diameter of the placement holes 701 is slightly larger than the diameter of the screw rod of the bolt.

[0050] The working process of this embodiment:

[0051] Bolts are placed on the base plate 71, and a reciprocating thrust is applied to the base plate 71. Due to the action of the elastic element 75 on the base 74, the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com