Swamp eel and loach deboning and killing machine

A loach and eel technology, applied in slaughtering, poultry/fish slaughtering/stunning, slicing fish, etc., can solve the problem of not being able to complete the eel and loach deboning requirements, and achieve small size, high work efficiency, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

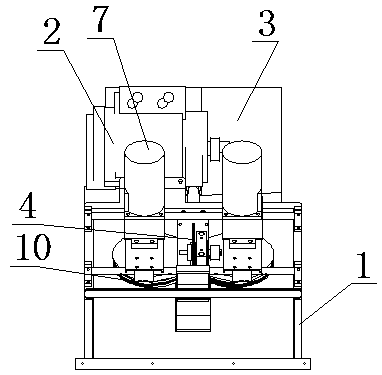

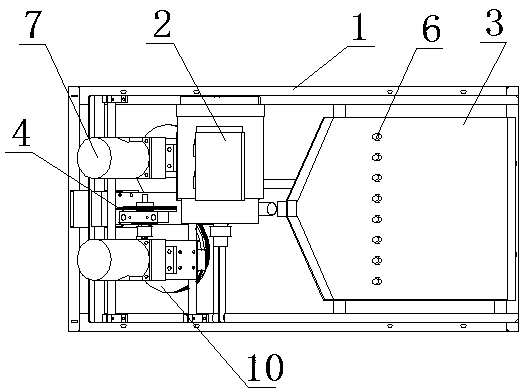

[0024] The eel and loach deboning and slaughtering machine includes a frame 1, a slaughtering motor 2, a feeding box 3 and a slaughtering and deboning hob 4. The upper end of the frame 1 is fixedly provided with a feeding box 3, and the feeding box 3 is in the frame 1. The top is inclined and installed in a low front and a high back; the top of the feeding box 3 is open, the box plate at one end (front) of the feeding box 3 is V-shaped, and the bottom of the V-shaped box plate is provided with a discharge pipe 5 to discharge the material. A plurality of blocking rods 6 are arranged in parallel on the bottom plate of the feed box 3 on one side of the pipe 5 . The function of the blocking rod 6 is to prevent the loach or eel poured into the feeding box 3 from accumulating at the port of the discharge pipe 5 during work, so as to block the discharge pipe 5, so that the loach or the eel cannot enter the discharge. Case of tube 5.

[0025] A sliding rod 7 is symmetrically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com