Method for manufacturing furniture using extruded polymer profiles

A technology for extruding profiles and polymers, used in furniture connections, furniture parts, home appliances, etc., to protect natural resources, increase transportation capacity, and reduce atmospheric emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

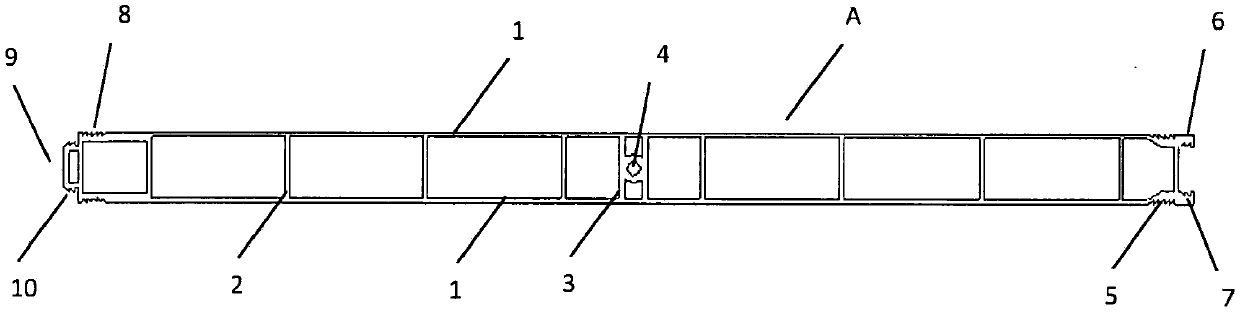

[0032] according to Figures 1 to 10 , the proposed furniture manufacturing method consists of extruding profiles using three pieces of honeycomb polymer, the profiles (A) being formed from thin elongated shapes provided with an outer wall (1) supported by an inner structural wall (2), showing In the center the support (3) can receive a screw (D) through a hole (4). The lateral end of the profile (A) has on one side an outer flexible flap (5), a flange (6) provided with an inner flexible flap (7). The opposite side end has an outer flexible flap (8) and a fitting (9) provided with an outer flexible flap (10).

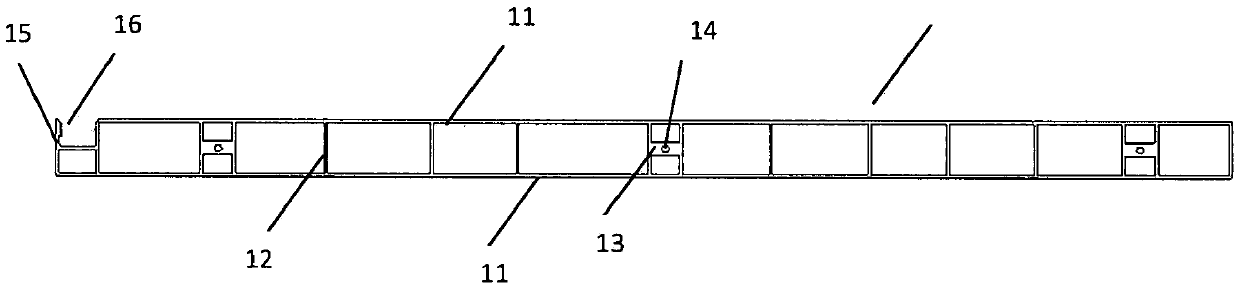

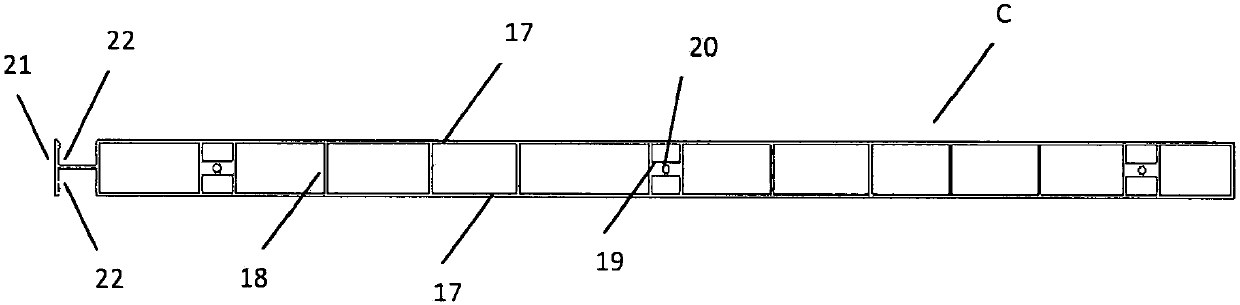

[0033] The profile (B) is formed by a thin elongated shape provided with an outer wall (11) supported by an inner structural wall (12), showing in the center a support (13) capable of receiving a screw (D) through a hole (14) . The lateral ends of the profile (B) show an angled structure (15) internally provided with external flexible flaps (16). The opposite side e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com