Photocatalytic coating material and sprayer product

A technology of photocatalyst and coating agent, which is applied in the direction of catalyst activation/preparation, molecular sieve catalyst, heterogeneous catalyst chemical elements, etc., and can solve skin dryness and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0027] The photocatalyst coating agent of the present embodiment includes: a dispersion medium containing water; photocatalyst fine particles dispersed in the dispersion medium; and silver ions. The concentration of the silver ion in the photocatalyst coating agent is 0.6 ppm or more.

[0028] A photocatalyst coating agent (photocatalyst coating liquid) is a suspension in which photocatalyst fine particles are dispersed in an aqueous dispersion medium, and is a coating agent for forming a photocatalyst layer on the surface of a substrate. The photocatalyst coating agent can also be packed in a storage container, a storage container, a spray bottle, or a spray product.

[0029] The method for coating the photocatalyst coating agent on the substrate surface is not particularly limited, but the method is, for example, spray coating, dip coating, screen printing, spin coating, brushing, roll coating, and roll coating (roll coating). coating) etc.

[0030] When the photocatalyst ...

no. 2 approach

[0049] The second embodiment relates to spray preparations. figure 1 It is a schematic sectional view of the spray product of this embodiment.

[0050] The spray product 20 includes the photocatalyst coating agent 2 of the first embodiment and the sprayer 3 configured to spray the photocatalyst coating agent 2 .

[0051] The sprayer 3 may include a trigger spray structure, the trigger spray structure is a pull trigger 11, the photocatalyst coating agent 2 in the chamber 8 is pressed by the plunger 10, and the photocatalyst coating agent is sprayed from the spray nozzle 9 2.

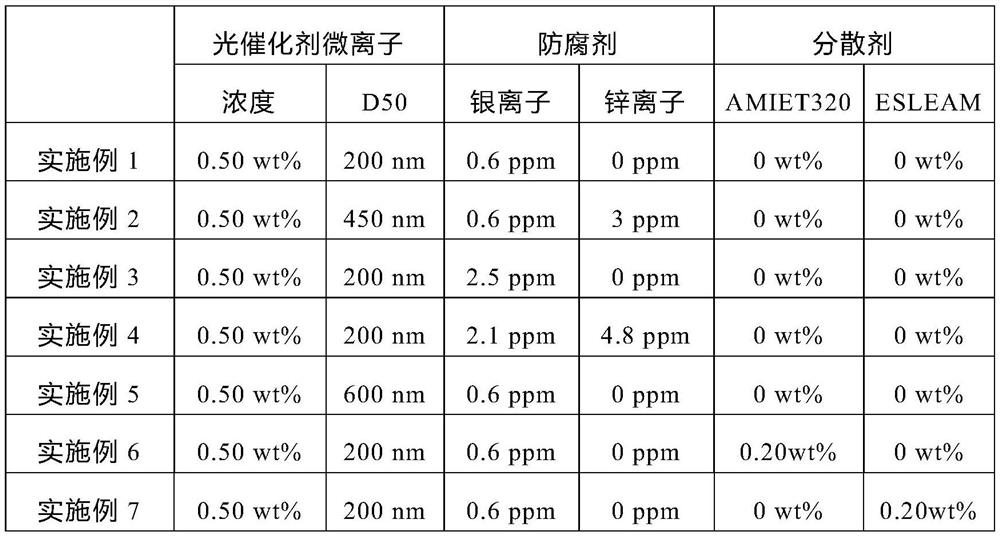

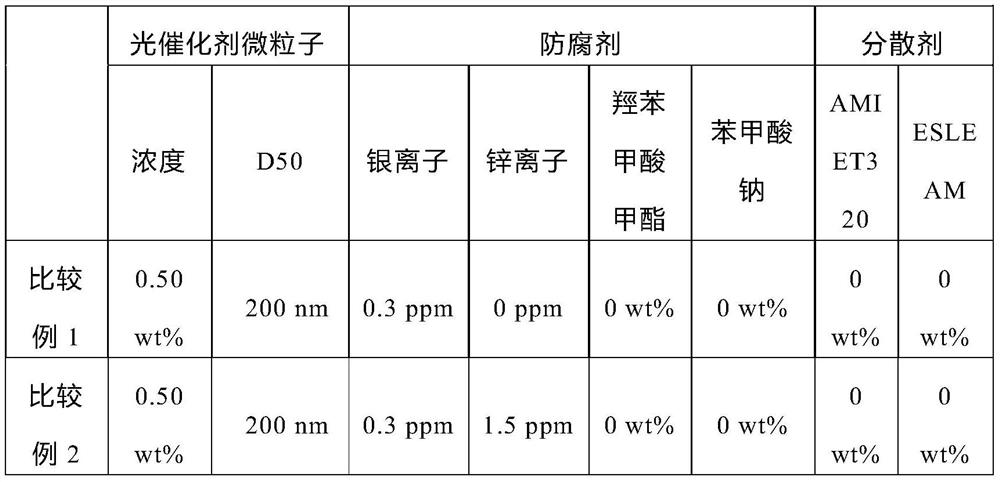

[0052] Preparation experiment of photocatalyst coating agent

Embodiment 1

[0055] Mix the slurry 2.3g, water 97.6g and composite agent 4mg (silver ion 0.06mg) of the photocatalyst microparticle dispersion of volume average particle diameter D50=200nm by the ratio of 21wt%, prepared photocatalyst coating agent 100ml, so 4 mg of the above-mentioned composite agent is a composite agent in which 1.5 wt % of silver ions are supported on zeolite fine particles. In photocatalyst microparticles, Pt-supported WO is used 3 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com