A method for arranging circular drainage pipes of pre-buried tunnels

A layout method and drainage pipe technology, applied in drainage, earthwork drilling, safety devices, etc., can solve problems such as extrusion and deformation of circumferential drainage pipes, and achieve the effect of reducing negative effects and excellent suction and drainage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below with the accompanying drawings ( Figure 1-Figure 6 ) to illustrate the present invention.

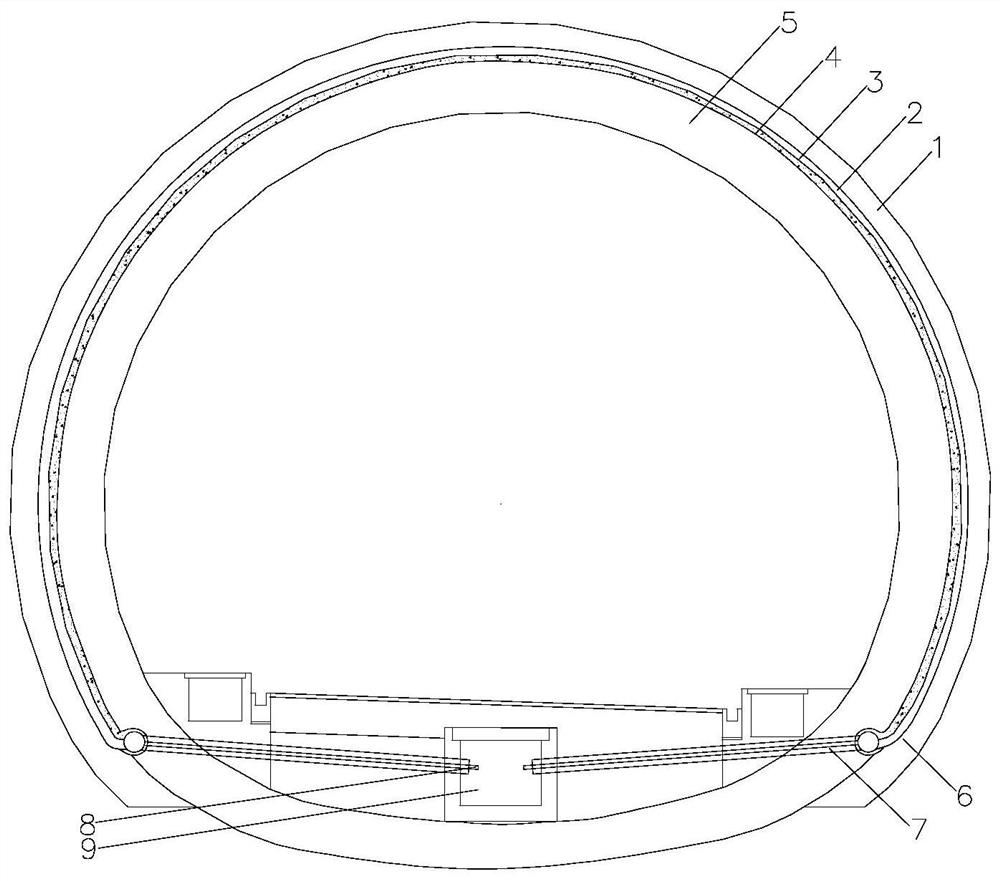

[0030] figure 1 It is a schematic diagram of the overall structure of the tunnel formed by implementing a pre-buried tunnel annular drainage pipe arrangement method of the present invention.

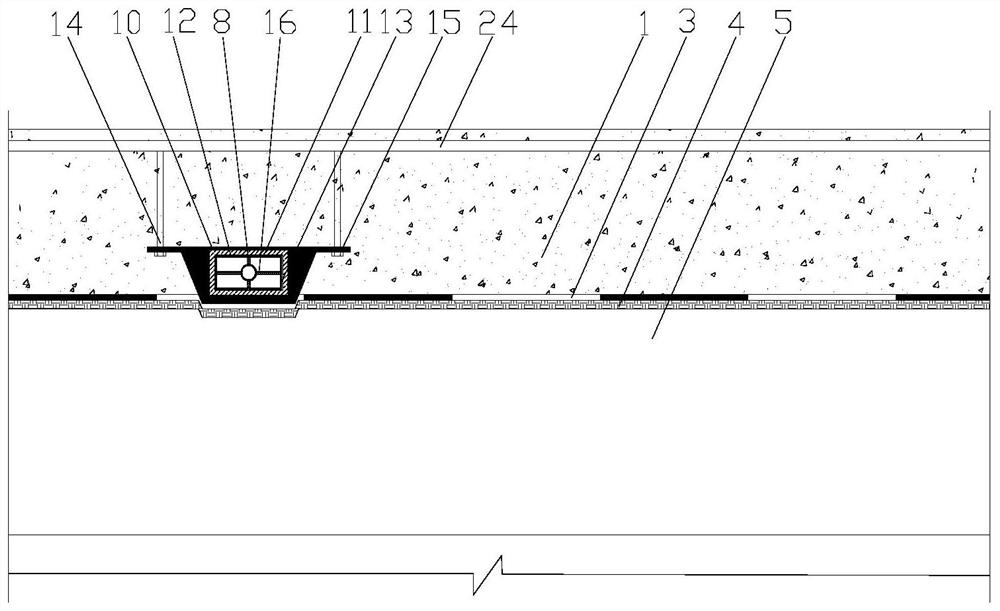

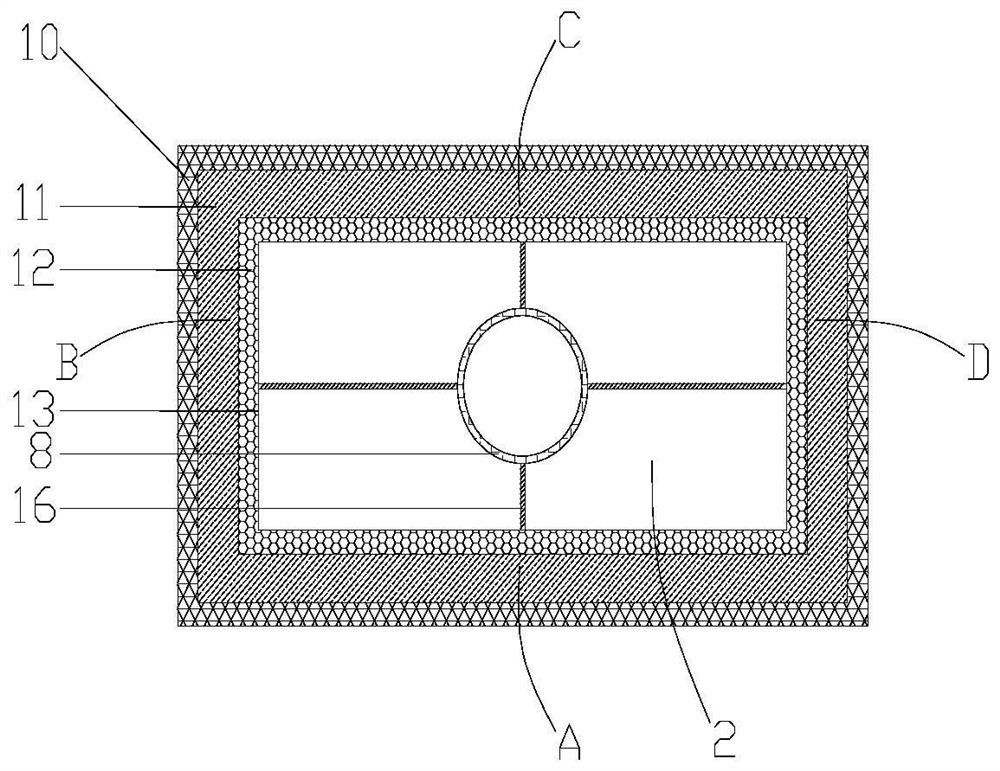

[0031] figure 2 yes figure 1 Schematic diagram of the structure of the tunnel. image 3 yes figure 2 Schematic diagram of the structure of the central drainage pipe. Figure 4 yes figure 2 Schematic diagram of the structure of the fixed groove. Figure 5 yes figure 2 Schematic diagram of the three-dimensional structure of the central drainage pipe. Figure 6 yes figure 2 Schematic diagram of the structure of the flushing inner tube. Such as Figure 1 to Figure 6As shown, a pre-buried tunnel circumferential drainage pipe layout method, the circumferential drainage pipe 2 is embedded in the initial support layer 1, the exposed surface of the bottom A of the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com