Fault fracture zone gravel and water discharging device used for tunnel construction

A drainage device and tunnel construction technology, applied in drainage, safety devices, mining equipment, etc., can solve problems such as the impact of sump pits, and achieve the effect of reducing barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

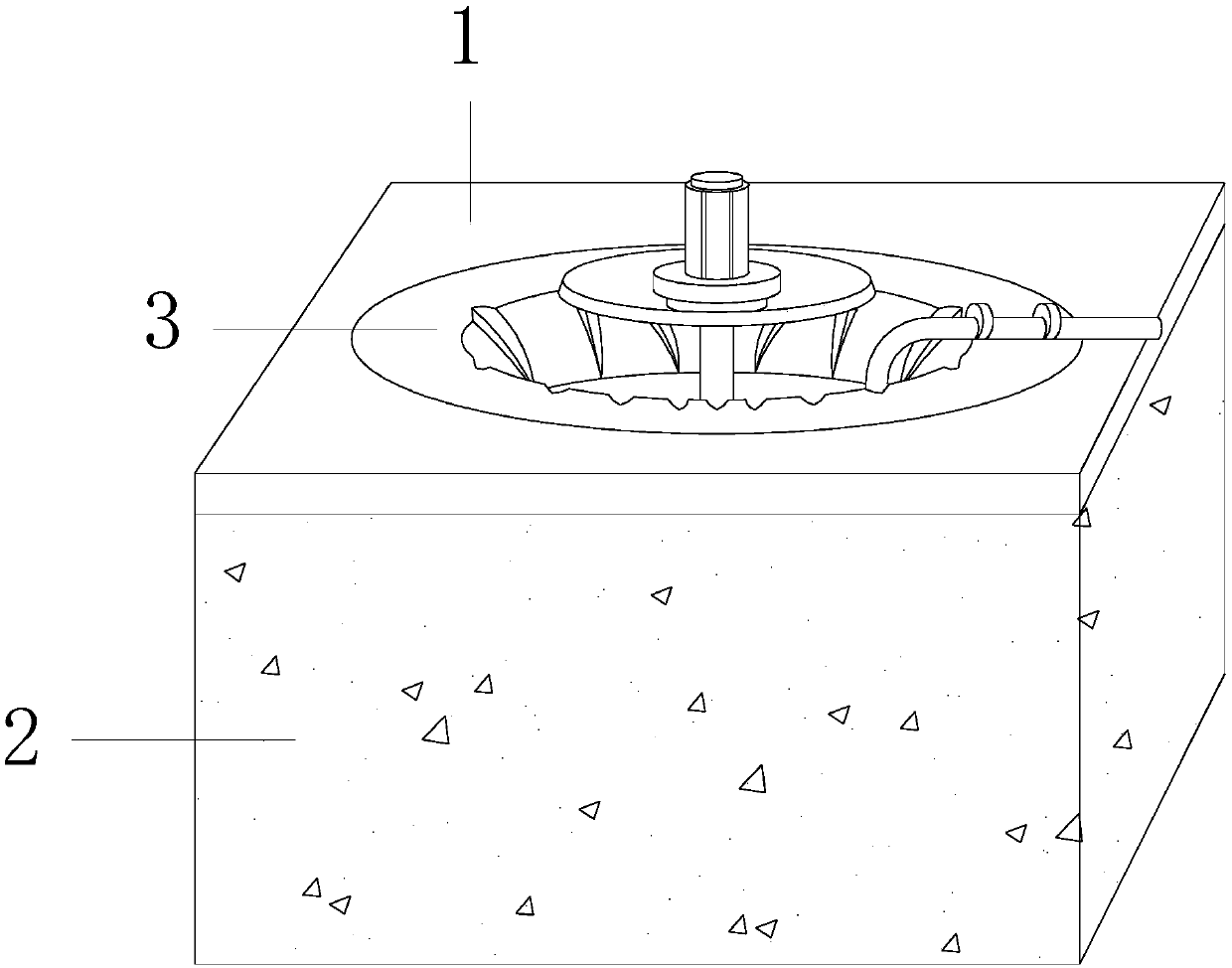

[0026] see Figure 1-Figure 6 , the present invention provides a rock drainage device for fault fracture zone for tunnel construction, its structure includes: a tunnel floor 1, a soil layer 2, a rock drainage device 3, the lower surface of the tunnel floor 1 and the upper surface of the soil layer 2 Correspondingly, the lower end of the rock discharge device 3 is embedded in the soil layer 2 .

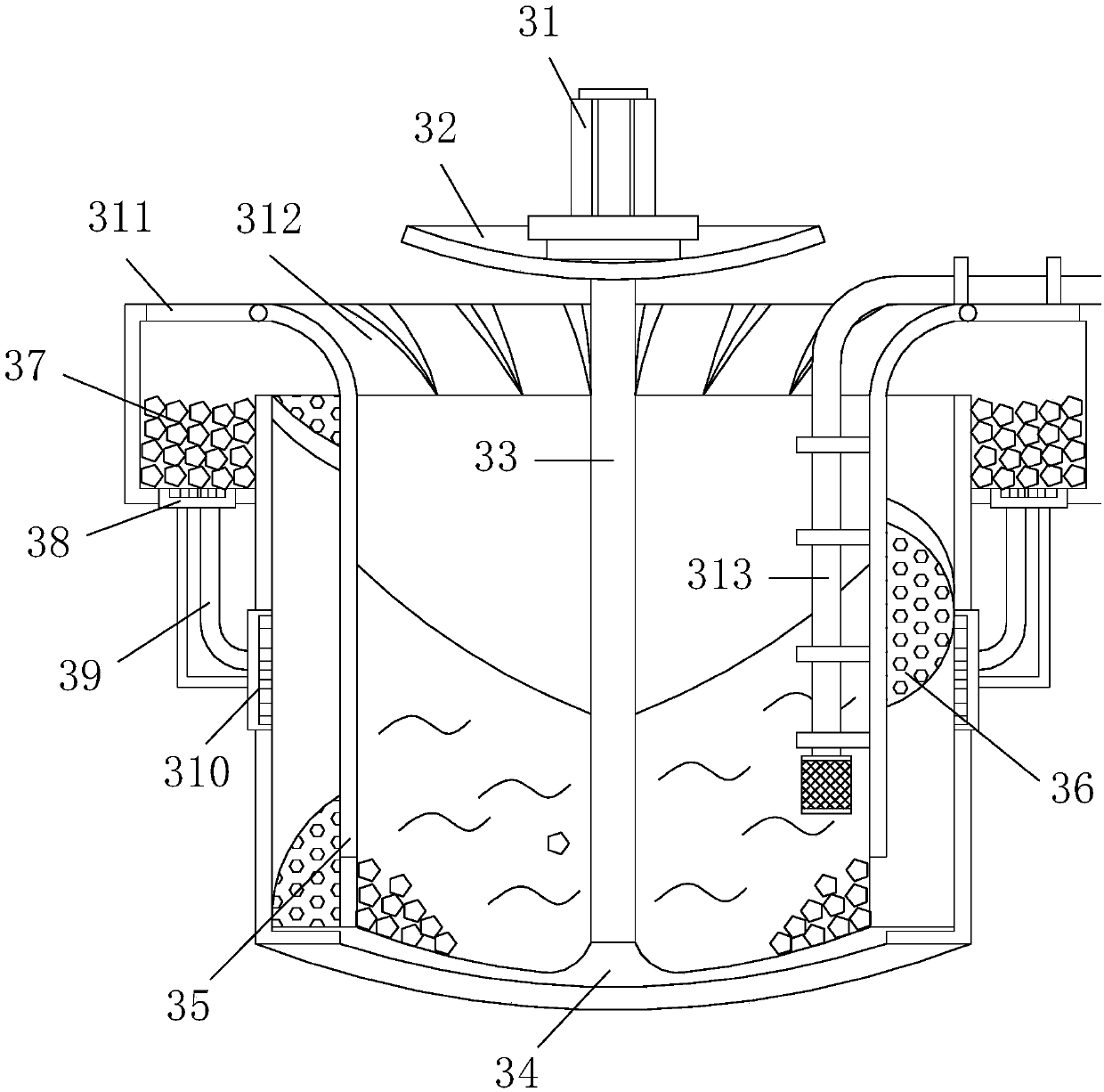

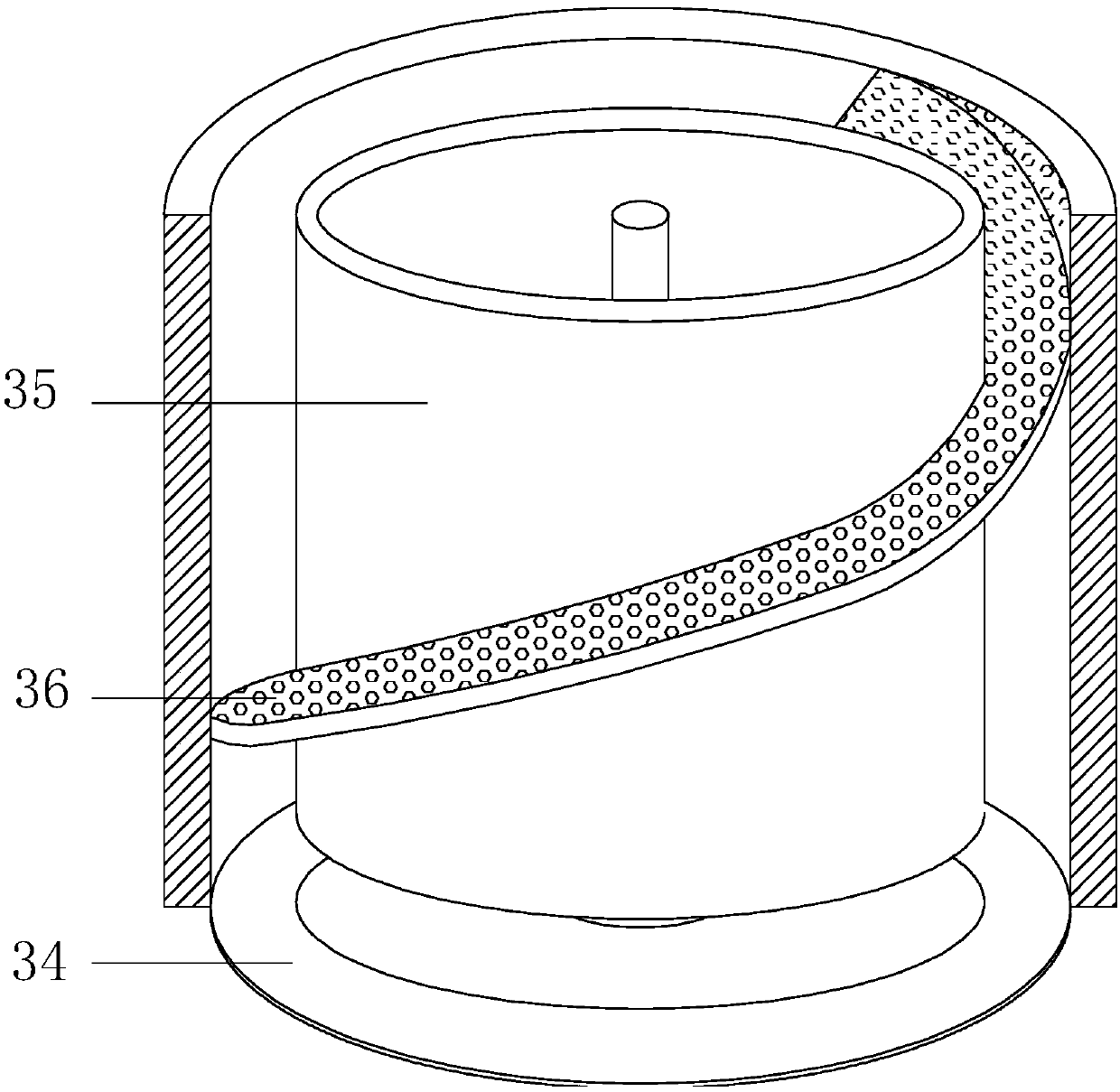

[0027] The sump 3 includes a motor 31, a water baffle 32, a rotating shaft 33, a turntable 34 at the bottom of the pit, a sump 35, a stone discharge belt 36, a stone collection chamber 37, a drainage groove 38, a water delivery pipe 39, an outlet 310, Stone discharge cover 311, water collection ring 312, water suction pipe 313, the motor 31 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com