Large pipeline non-cutout dredging and desilting construction method

A construction method and pipeline technology, which is applied in the direction of cleaning sewer pipes, waterway systems, water supply devices, etc., can solve the problems of dredging and dredging of large-scale main pipe networks, high economic and environmental costs, and large volume of sludge water, etc., to achieve dredging and cleaning silt problem, promotion of environmental protection, and construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

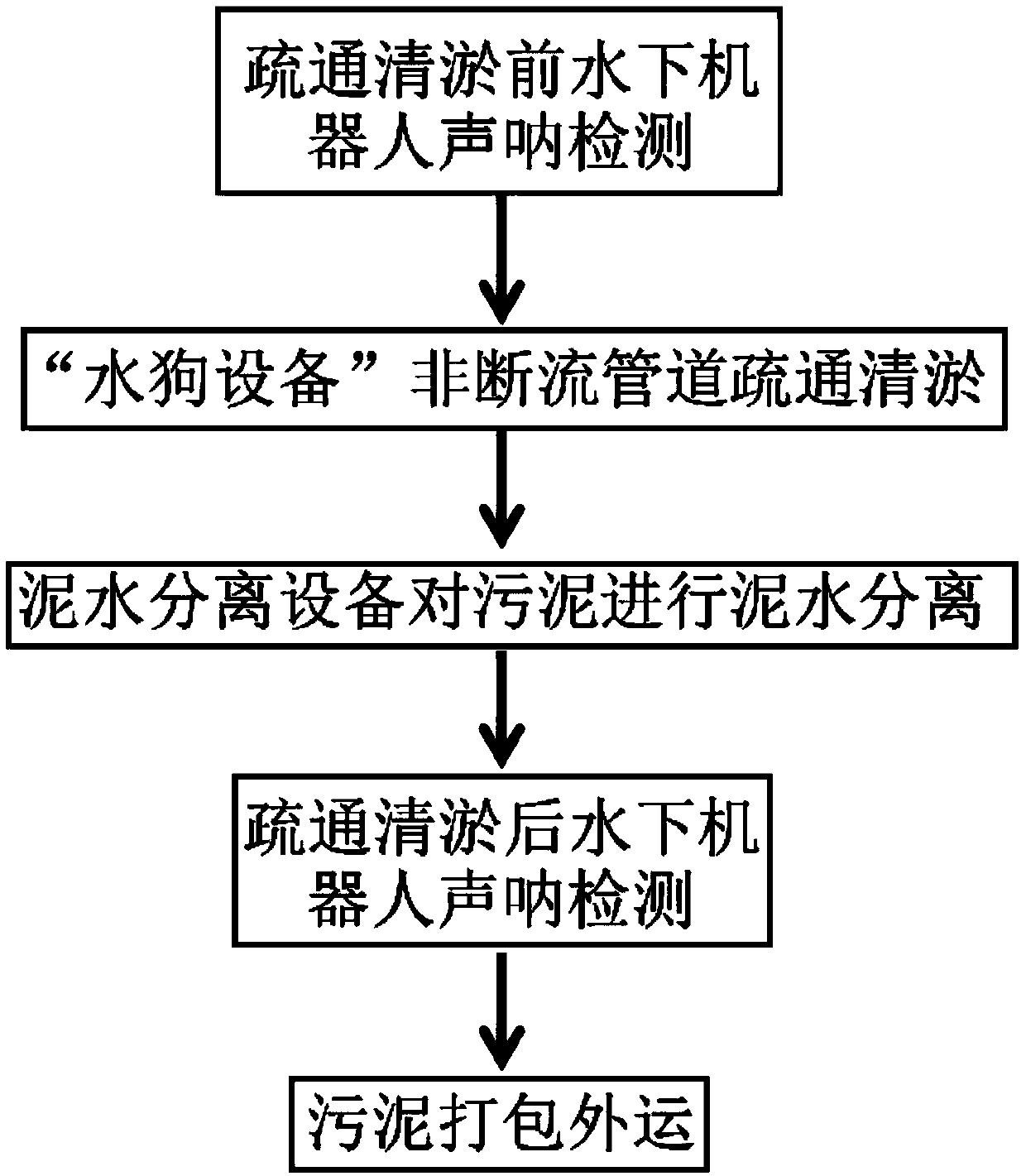

Method used

Image

Examples

example

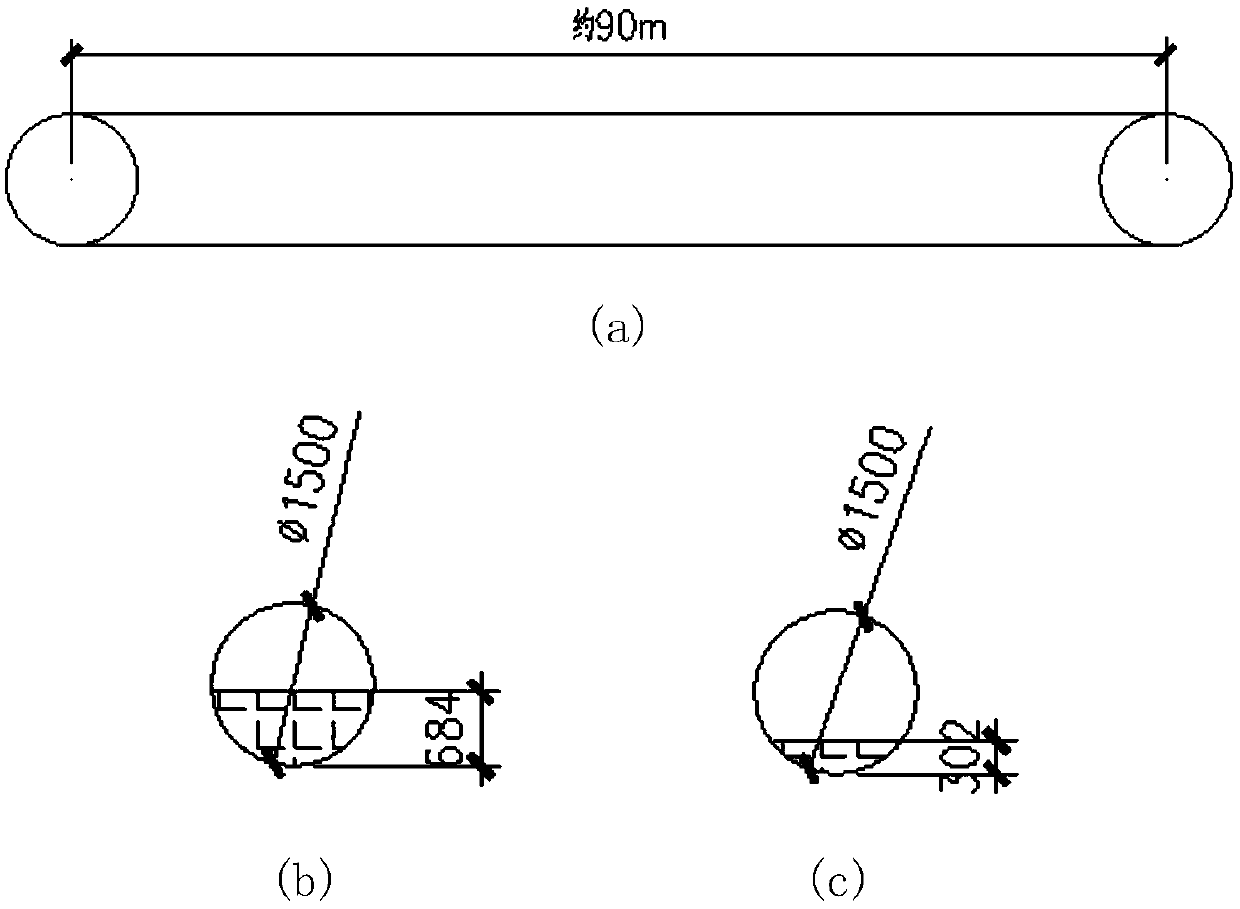

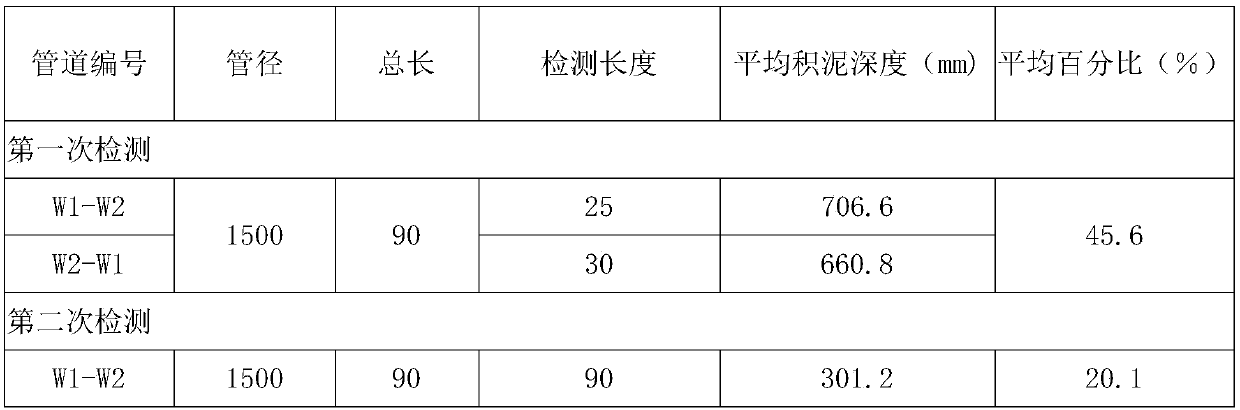

[0035] Example: Large experimental pipe sections such as figure 2 As shown in (a), the pipe is about 90 meters long and 1.5 meters in diameter. Before the experimental pipe section is desilted, the height of the sludge in the pipe is 0.684 meters, as figure 2 (b), dredging and dredging under the condition of continuous flow, after separation, the volume of sludge relative to muddy water is greatly reduced, and the height of sludge in the pipeline is 0.302 meters, see figure 2 (c), the water quality of the chemically treated sewage is clear, and it flows back into the sewage pipe for normal circulation. Judging from the evaluation statistics (see Table 1) of the sonar secondary detection pipeline, the dredging and dredging construction method of the present invention can solve the problem of dredging and dredging large-scale pipelines, and also greatly reduces silt.

[0036] Table 1 Sonar detection pipeline evaluation statistics

[0037]

[0038] Note: W1-W2 direction d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com