Anti-freezing expansion system for catenary strut foundation and preparation process thereof

A technology of anti-frost heaving and catenary, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of low reliability, non-recoverable, short service life, etc., and achieve the effect of reasonable structure, convenient installation, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

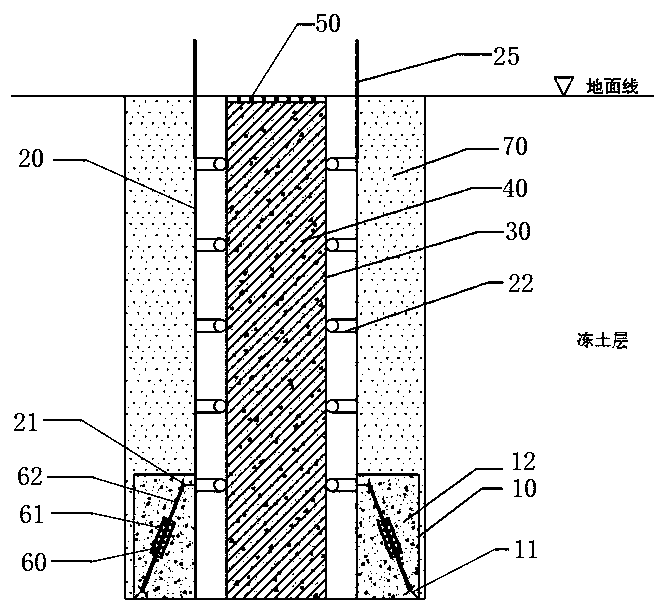

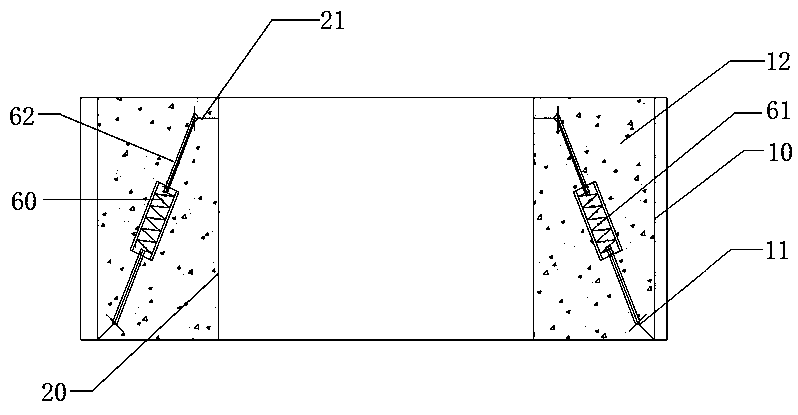

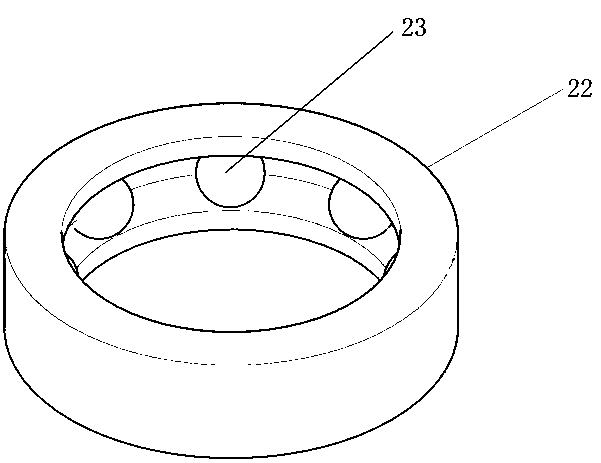

[0059] An anti-frost heave system for catenary pillar foundation, such as Figure 1-3 As shown, it includes a pipe bottom sleeve 10, a frozen drawn steel pipe 20, a rolling structure, a pillar outer sleeve 30, a pillar 40, a flange 50 and a gravel layer 70;

[0060] Wherein, the tube bottom sleeve 10 has a cylindrical structure as a whole. In this embodiment, it is made of stainless steel and is divided into two symmetrical parts, which are fixedly connected by bolt assemblies. Shaped opening, the first spring joint 11 is installed on the inner bottom periphery of the tube bottom sleeve 10, in this embodiment, four first spring joints 11 are evenly installed on the bottom periphery;

[0061] Wherein, the frozen-drawn steel pipe 20 has a cylindrical structure as a whole. In this embodiment, the frozen-drawn steel pipe is composed of two semicircular structures connected by bolts, and the lower end is inserted into the pipe bottom sleeve through the opening at the top of the pip...

Embodiment 2

[0082] An anti-frost heave system for catenary pillar foundations, comprising a pipe bottom sleeve 10, a frozen drawn steel pipe 20, a rolling structure, a pillar outer sleeve 30, a pillar 40, a flange 50 and a gravel layer 70;

[0083] Wherein, the tube bottom sleeve 10 has a cylindrical structure as a whole. In this embodiment, it is made of stainless steel and is divided into two symmetrical parts, which are fixedly connected by welding. The bottom of the tube bottom sleeve 10 is closed, and a round Holes are opened, and first spring joints 11 are installed around the inner bottom of the tube bottom sleeve 10. In this embodiment, four first spring joints 11 are evenly installed around the bottom;

[0084] Wherein, the frozen-drawn steel pipe 20 has a cylindrical structure as a whole. In this embodiment, the frozen-drawn steel pipe is composed of two semicircular structures connected by bolts, and the lower end is inserted into the pipe bottom sleeve through the opening at th...

Embodiment 3

[0104] An anti-frost heave system for catenary pillar foundation, such as Figure 4 and Figure 5 As shown, it includes a pipe bottom sleeve 10, a frozen drawn steel pipe 20, a rolling structure, a pillar outer sleeve 30, a pillar 40, a flange 50 and a gravel layer 70;

[0105] Wherein, the tube bottom sleeve 10 has a cylindrical structure as a whole. In this embodiment, it is made of stainless steel and is divided into two symmetrical parts, which are fixedly connected by bolt assemblies. Shaped openings, the first spring joints 11 are installed on the inner bottom periphery of the tube bottom sleeve 10, in this embodiment, six first spring joints 11 are evenly installed on the bottom periphery;

[0106] Wherein, the frozen-drawn steel pipe 20 has a cylindrical structure as a whole. In this embodiment, the frozen-drawn steel pipe is composed of two semicircular structures connected by bolts, and the lower end is inserted into the pipe bottom sleeve through the opening at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com