Glyoxylic acid continuous oxidation process

An oxidation process, glyoxylic acid technology, applied in organic chemistry, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of poor product quality stability, frequent process operations, and high equipment usage, and achieve stable product quality. Good performance, high selectivity and yield, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

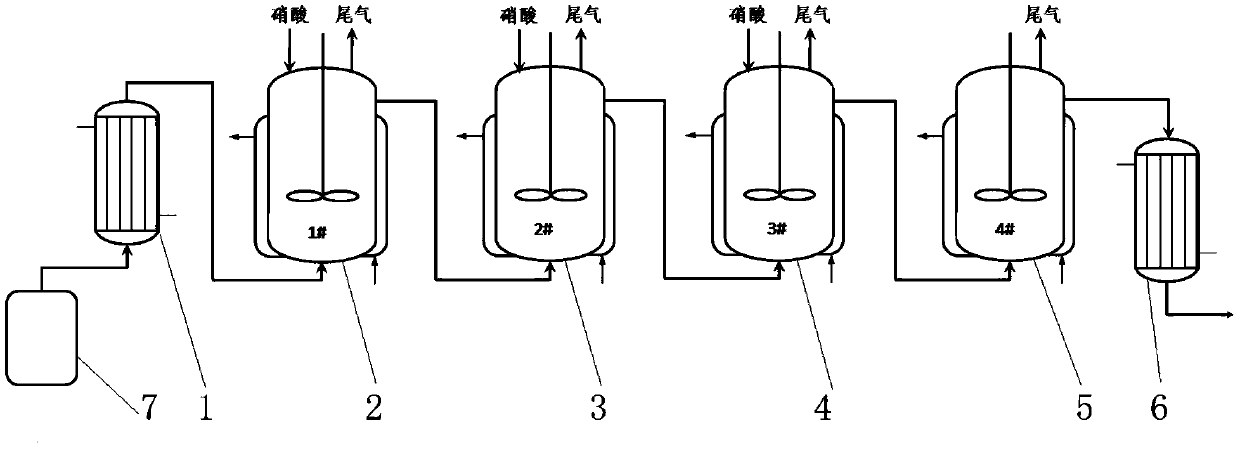

[0026] A kind of glyoxylic acid continuous oxidation technique, the structure of the device that this technique adopts is as figure 1 As shown, it is composed of a preheater 1, an initiation kettle 2, a first oxidation kettle 3, a second oxidation kettle 4, a holding kettle 5 and a cooler 6 connected in sequence, and the preheater is also connected with a mixer 7, and the mixer is used for Mix hydrochloric acid, initiator and glyoxal.

[0027] 100kg of glyoxal aqueous solution with mass concentration of 40wt%, 10kg of hydrochloric acid aqueous solution with mass concentration of 31wt%, and 10kg of nitric acid aqueous solution with mass concentration of 10wt% are continuously mixed through a mixer and heated to 60°C by a heater. Enter the initiator tank, and at the same time, dropwise add nitric acid with a mass concentration of 60wt% at a rate of 25kg per minute under continuous stirring conditions, and then the reaction will begin, and the reaction temperature will be control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com