Two-temperature phase-change temperature-variable swelled vermiculite plate and preparation method thereof

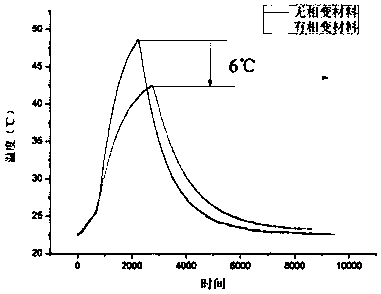

A technology of expanded vermiculite board and expanded vermiculite, which is applied in the field of phase change energy storage materials, can solve the problems of not realizing the integration of structure and function of building materials, increasing the amount of engineering, etc., and achieve the effect of saving packaging steps and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Select 0.8mol / L sodium hydroxide solution to react with diatomaceous earth at 75°C for 1h, take the filtered and dried diatomite and pentadecane and stir at 40°C for 1h, then dissolve the blend at 40°C Ultrasonic treatment at ℃ for 1.5h to prepare diatomite composite phase change material; use 0.7mol / L sulfuric acid to react with expanded vermiculite at 60℃ for 1h, take filtered and dried expanded vermiculite and paraffin at 60℃ The exfoliated vermiculite composite phase change material was prepared by stirring for 2h under the same conditions, and then ultrasonically treating the co-melt at 60°C for 1h.

[0032] The dual-temperature expanded vermiculite board consists of the following components by mass: 15 parts of diatomite composite phase change material, 25 parts of expanded vermiculite composite phase change material, 40 parts of Portland cement, 0.4 part of water reducer, and 30 parts of water.

[0033]The preparation method of the dual-temperature phase-change t...

Embodiment 2

[0040] Select 0.5mol / L sodium hydroxide solution to react with diatomaceous earth at 65°C for 2h, take the filtered and dried diatomite and nonanoic acid and stir at 50°C for 1h, then dissolve the blend at 50°C Under the conditions of ultrasonic treatment for 1.5h, the diatomite composite phase change material was prepared; 0.6mol / L sulfuric acid was selected to react with expanded vermiculite at 75°C for 2h, and the filtered and dried expanded vermiculite and paraffin were heated at 70°C After stirring for 2h, the co-melt was ultrasonically treated at 70°C for 1h to prepare the expanded vermiculite composite phase change material.

[0041] The dual-temperature expanded vermiculite board consists of the following components by mass: 20 parts of diatomite composite phase change material, 30 parts of expanded vermiculite composite phase change material, 60 parts of Portland cement, 0.5 parts of water reducer, and 40 parts of water.

[0042] The preparation method of the dual-tem...

Embodiment 3

[0049] Select 1mol / L sodium hydroxide solution to react with diatomite at 65°C for 3h, take the filtered and dried diatomite and pentadecane and stir at 60°C for 1h, and then dissolve the blend at 60°C Under the conditions of ultrasonic treatment for 1.5h, the diatomite composite phase change material was prepared; 1mol / L sulfuric acid was selected to react with expanded vermiculite at 80°C for 4h, and the filtered and dried expanded vermiculite and paraffin were heated at 80°C After stirring for 2h, the co-melt was ultrasonically treated at 80℃ for 1h to prepare the expanded vermiculite composite phase change material.

[0050] The dual-temperature expanded vermiculite board is composed of the following components by mass: 10 parts of diatomite composite phase change material, 30 parts of expanded vermiculite composite phase change material, 40 parts of Portland cement, 0.5 parts of water reducer, and 35 parts of water.

[0051] The preparation method of the dual-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com