Blow molding plate structure

A panel structure and plastic panel technology, applied in the field of blow-molded panel structure, can solve the problems of blow-molded panels that are not conducive to self-adaptive bending, limited use occasions, and poor compression resistance, and achieve novel structure, reduced ground pressure, The effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

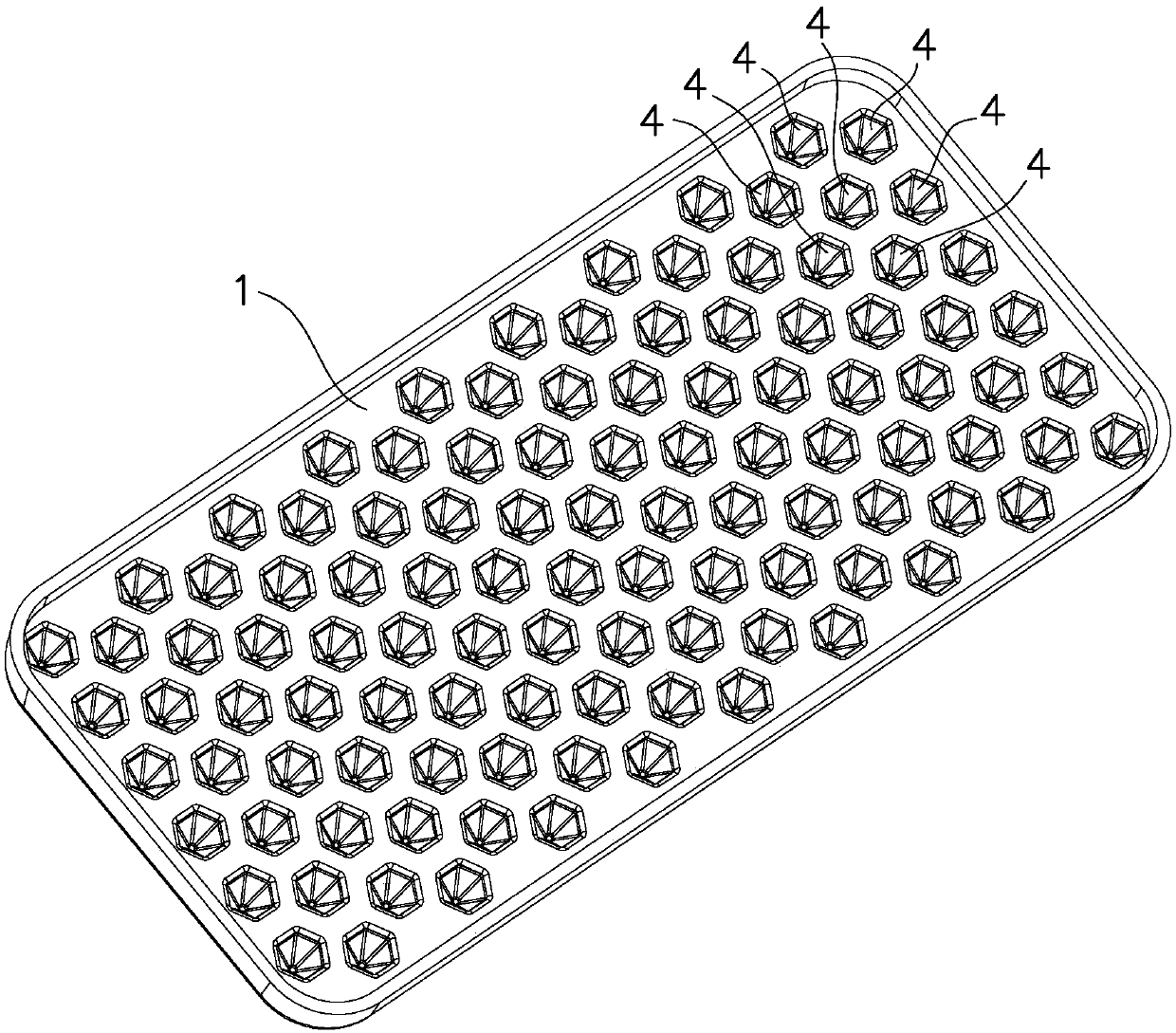

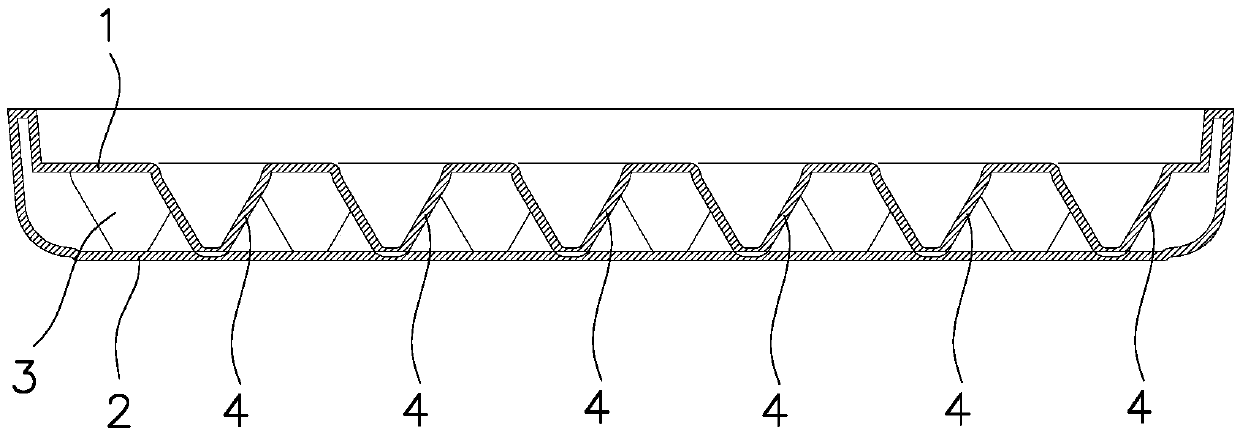

[0025] Such as Figure 1 to Figure 2 As shown, the blow-molded board in this embodiment includes a first surface layer 1 and a second surface layer 2, a hollow structure 3 is formed between the first surface layer 1 and the second surface layer 2, and the first surface layer 1 and the second surface layer 2 are integral Formed structure, a honeycomb structure consisting of concave bumps 4 is molded over the entire area of the first skin 1 . The concave bump 4 is set inwardly from the first surface layer 1, and the head of the concave bump 4 touches the second surface layer 2, and the concave bump 4 gradually moves from the first surface layer 1 to the second surface layer 2. Gather up, and there is a point contact between the head of the concave bump 4 and the second surface layer 2 . After adopting the concave contact point 4, stress conduction can be realized between the first surface layer 1 and the second surface layer 2, thereby obviously improving the structural stren...

Embodiment 2

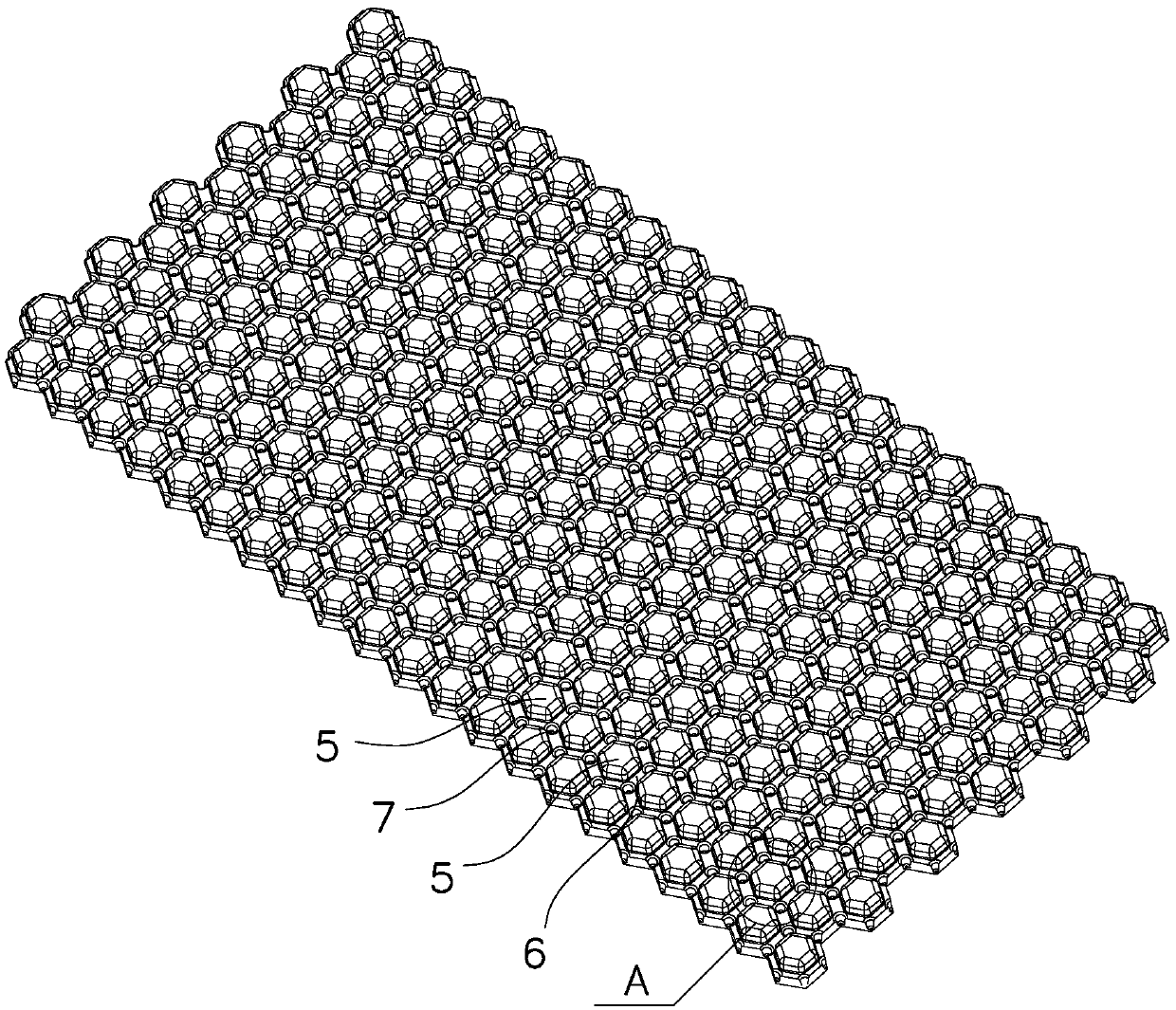

[0029] Such as Figure 3 to Figure 6 As shown, the blow-molded board of this embodiment includes a first surface layer 1 and a second surface layer 2, a hollow structure 3 is formed between the first surface layer 1 and the second surface layer 2, and the first surface layer 1 and the second surface layer 2 are integrally formed structure, a honeycomb structure composed of bumps 5 is molded on the entire area of the first surface layer 1 , and the bumps 5 protrude outward from the first surface layer 1 .

[0030] In this embodiment, the cross section of the bump 5 is a regular hexagon. Correspondingly, a corresponding regular hexagonal groove 6 is naturally formed around a bump 5, so that the overall distribution of the bump 5 is novel, unique and decorative. Strong, enhance the aesthetics of the product. In addition, the groove 6 is concavely formed with contact points 7 that contact the second surface layer 2 , and the contact points 7 are evenly distributed around the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com