A continuous working device for oil-water separation

A working device and oil-water separation technology, applied in separation methods, liquid separation, immiscible liquid separation, etc., can solve the problem of low oil-water separation efficiency and achieve rapid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

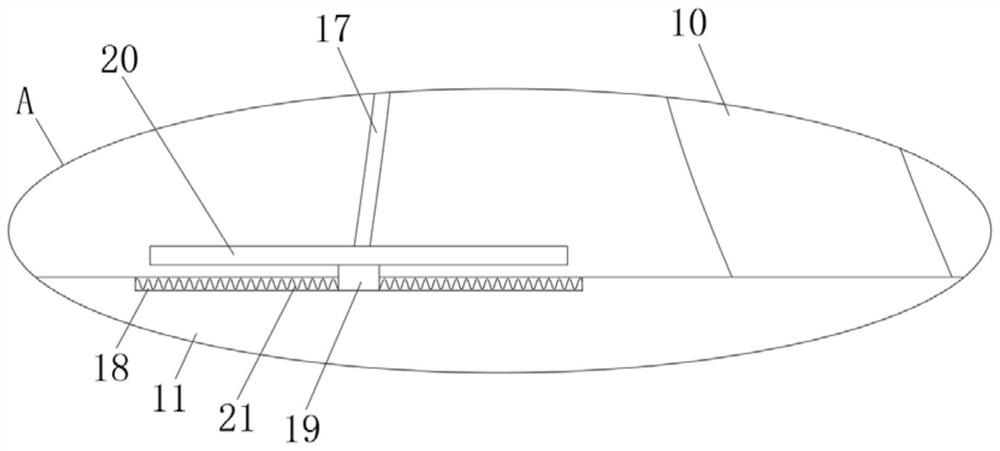

[0018] refer to Figure 1-3 , a continuous working device for oil-water separation, including a turntable 1 and a mixing box 2, the oil extracted from the oil field directly leads to the interior of the mixing box 2, the bottom of the mixing box 2 is sealed and slidingly connected with the box bottom 3, and the side wall of the mixing box 2 It is fixedly connected with the external bracket to make its position stable;

[0019] The lower end of the turntable 1 is concentrically welded and fixed with a motor 16, and a plurality of separation pools 4 are annularly arranged on the turntable 1. A feed pipe 5 is sealed and welded through the middle of the upper end of each separation pool 4, and each feed pipe 5 is welded with the bottom 3 of the box. Fixed, the oil in the mixing box 2 can enter the interior of the separation pool 4 through the feed pipe 5, a round bar 6 is welded in the middle of each separation pool 4, and a follow-up device is slidably connected on the round bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com